- Overview

- Recommended Products

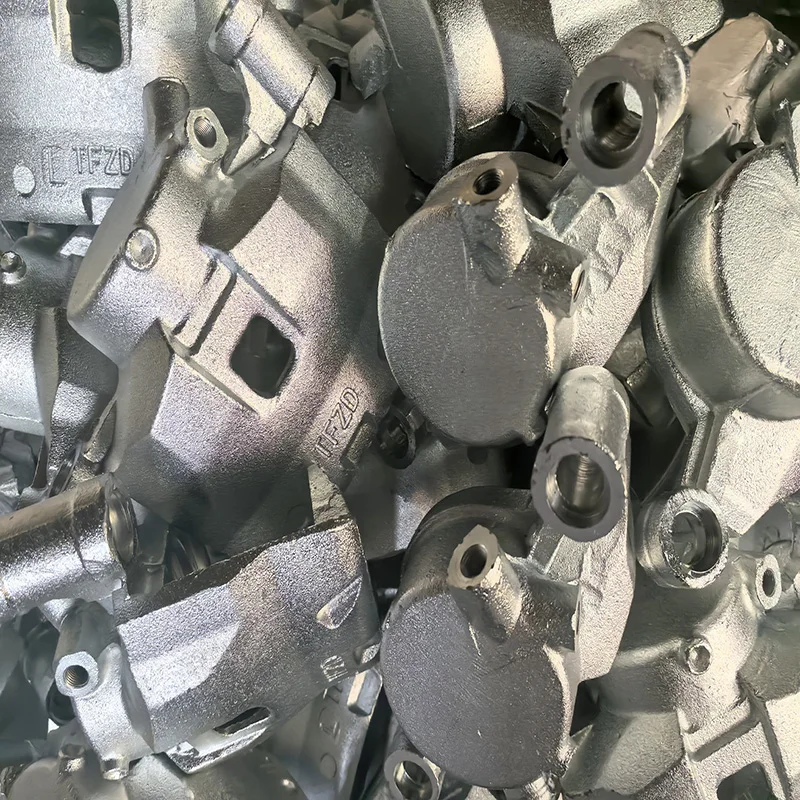

In the critical world of flow control, the valve bonnet serves as a primary seal and structural component, housing the stem and ensuring safe operation under pressure. Our Cast Iron Valve Bonnet, produced through expert sand casting services, offers a robust and cost-effective solution for a wide range of industrial applications. This product exemplifies the perfect marriage of a time-tested material with a versatile manufacturing process to deliver uncompromising reliability.

Superior Material: High-Strength Cast Iron

The performance of this bonnet begins with its material. We primarily use Grade 250 Gray Cast Iron and Ductile (Nodular) Iron. Gray Iron (ASTM A48) is chosen for its excellent castability, good machinability, and outstanding damping capacity, which absorbs vibration. For more demanding applications, Ductile Iron (ASTM A536) is employed. Its spherical graphite inclusions provide superior tensile strength, impact resistance, and elongation, offering performance characteristics approaching those of steel, but with greater castability and at a lower cost.

Performance and Engineering Integrity

Designed to be the backbone of a reliable valve assembly, our cast iron bonnets are engineered for:

Pressure Integrity: Manufactured to withstand specified pressure ratings (e.g., ANSI Class 125/150) without deformation or leakage.

Corrosion Resistance: Suitable for a wide range of media, including water, oil, steam, and gases, with optional coatings for enhanced protection.

Dimensional Stability: The rigid cast iron construction ensures the valve stem alignment is maintained, guaranteeing smooth operation and long-term seal integrity.

Advanced Sand Casting and Finishing Process

Our bonnets are produced using high-quality sand casting techniques. This process involves creating a precise mold from a resin-bonded sand mixture, which allows for great flexibility in design and the production of complex geometries. After the molten iron is poured and solidifies, the casting undergoes critical post-processing:

Shot Blasting: Cleans the surface and improves fatigue resistance.

Heat Treatment: (For Ductile Iron) Annealing is applied to enhance ductility and machinability.

Precision Machining: CNC milling and turning operations are performed on all critical sealing surfaces, flange faces, and thread bores to ensure exact dimensional accuracy and a perfect fit with the valve body and packing.

Wide-Ranging Industrial Applications

Our sand-cast iron valve bonnets are essential components across numerous industries, including:

Water & Wastewater: For gate, globe, and check valves in distribution and treatment systems.

Oil & Gas: Used in low-pressure pipeline and processing applications.

Chemical Processing: Suitable for handling various chemicals with appropriate lining or coating.

HVAC and Plumbing: A standard in commercial and industrial building systems for steam and water control.

General Industrial Machinery: For pumps, compressors, and other fluid handling equipment.

For a durable, high-performance, and economically efficient valve bonnet, our cast iron sand casting services provide the ideal solution. Trust in a product built for longevity and reliability in demanding environments.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |