Pengxin

Presentiamo il Volano per Auto Pengxin in Ghisa (GG25) Realizzato con Fusione in Sabbia con Ingranaggio Montato - un componente automobilistico di alta qualità e affidabile, progettato per offrire prestazioni e durata eccezionali per il tuo veicolo.

Realizzato con materiale in ghisa di alta qualità, questo volano è stato prodotto con fusione in sabbia per garantire resistenza e lunga durata. Il materiale GG25 offre un'elevata resistenza all'usura e un'ottima dissipazione del calore, rendendolo ideale per resistere alle sollecitazioni della guida quotidiana.

Il Volano per Auto Pengxin presenta una superficie lavorata con precisione che assicura un montaggio perfetto e un funzionamento regolare. L'ingranaggio è installato in modo impeccabile sul volano, creando Pengxin un collegamento robusto e sicuro che non slitta né si consuma prematuramente.

Questo volano è specificamente progettato per un'installazione semplice, rendendolo una scelta adatta sia ai meccanici fai-da-te che ai professionisti. La costruzione resistente e la precisione delle lavorazioni garantiscono una prestazione affidabile su cui poter contare negli anni a venire.

Che tu guidi un'auto compatta, un camion pesante o qualsiasi veicolo intermedio, il volano per auto Pengxin in ghisa (GG25) realizzato con tecnica di fusione in sabbia con ingranaggio installato è la scelta ideale per migliorare le prestazioni e l'affidabilità del tuo veicolo. Dì addio ai pattini di frizione e ai cambi marcia irregolari e sperimenta un trasferimento di potenza uniforme e affidabile con il volano per auto Pengxin.

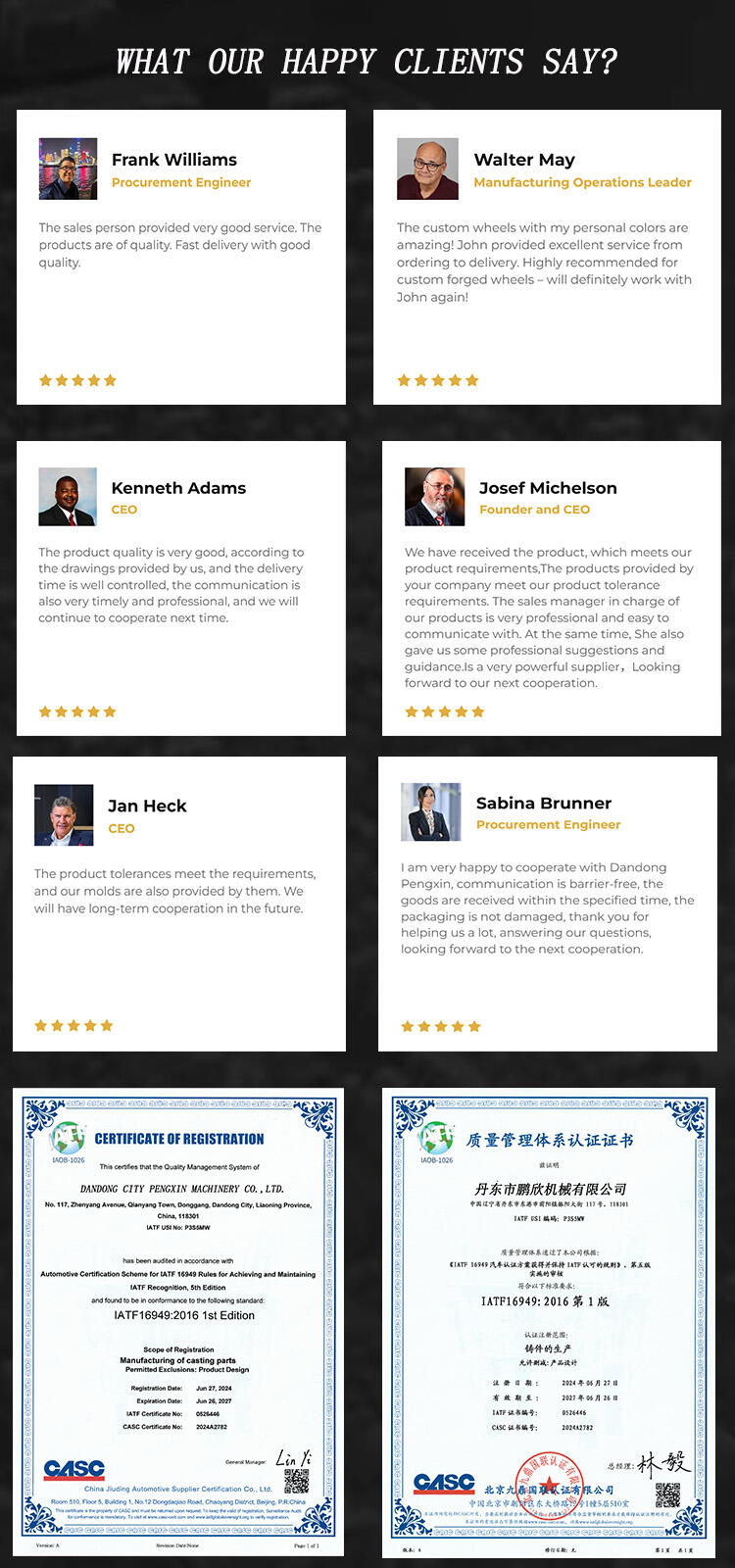

Fidati del marchio Pengxin per componenti automobilistici di alta qualità, progettati per superare gli standard del settore. Con l'impegno per l'eccellenza e la soddisfazione del cliente, Pengxin garantisce che ogni prodotto venga sottoposto a test rigorosi e ispezioni per rispettare gli standard più elevati di qualità e prestazioni.

Aggiorna il sistema di trasmissione del tuo veicolo con il volante della macchina Pengxin Cast Iron (GG25) Sand Casting Car Flywheel con installazione dell'anello di marcia e prova la differenza che l'ingegneria e la costruzione di qualità possono fare. Prendi il controllo delle prestazioni e dell'affidabilità del tuo veicolo con Pengxin, il marchio di cui ti puoi fidare per i ricambi per auto di alta qualità.

Perché siamo considerati esperti OEM nei collettori di scarico |

Ogni anno sviluppiamo oltre 100 diversi tipi di collettori di scarico |

|

|

|

Processo produttivo Dandong Pengxin per collettore di scarico |

Preparazione del Disegno: La Base della Precisione, Scansione 3D e Disegno: I nostri ingegneri professionisti utilizzano scanner avanzati per convertire i campioni in disegni 2D/3D (7–10 giorni). |

|

|

|

Sviluppo di Modello e Campione: Dove l'Investimento di Tempo Dà Ritorno |

Complessità: I collettori di scarico richiedono spesso 3–5 set di modelli in metallo (contro 1 set per fusioni più semplici). Tempi di Consegna: 35–40 giorni per modelli multi-cavità; 25–30 giorni per design più semplici. |

|

|

|

Ordini Iniziali e Produzione Seriale: Crescere in modo Responsabile |

Assegnazione delle Macchine: Un ordine di manifold potrebbe occupare 2–3 macchine per la modellazione. La nostra struttura con 16 macchine priorizza gli ordini urgenti e collabora con fonderie partner per i nuclei ausiliari. |

|

|

|

Come gli investitori possono mitigare i ritardi |

Pianificare 8–12 settimane per lo sviluppo di modelli/campioni. Ridurre questa tempistica comporta rischi per la qualità. Le prime serie richiedono il 20–30% in più di tempo a causa dell'affinamento dei processi. Dopo l'approvazione, i tempi di consegna si stabilizzano. |

|

|

|

Chi siamo

Dandong Pengxin Machinery Co., Ltd., fondata nel 1958, è un'azienda privata specializzata in fusione, lavorazione meccanica e assemblaggio. Con una superficie totale di 66.000 m², di cui 40.000 m² dedicati a officine, possiede beni per 40 milioni di dollari e conta 330 dipendenti, tra cui 46 tecnici. La capacità annuale raggiunge le 100.000 tonnellate.

Dotata di tecnologie avanzate come la modellazione ad alta pressione e le linee di produzione giapponesi FBO Ⅲ, può produrre fino a 30.000 tonnellate/anno. Le strutture includono forni elettronici a 12 impulsi, macchine CNC e un centro di controllo qualità dotato di strumenti precisi.

Vende in oltre 80 paesi e regioni del mondo, servendo grandi aziende come John Deere, Mercedes-Benz e Weir. Pengxin accoglie con favore collaborazioni, dando priorità alla qualità, al servizio e alla soddisfazione del cliente.

Pre-vendita

Definisci le tue esigenze di acquisto → Conferma il disegno dell'ordine → Fornisci una soluzione personalizzata → Emetti un preventivo → Crea il modello → Fornisci campioni → Produzione in serie dopo l'approvazione dei campioni

In vendita

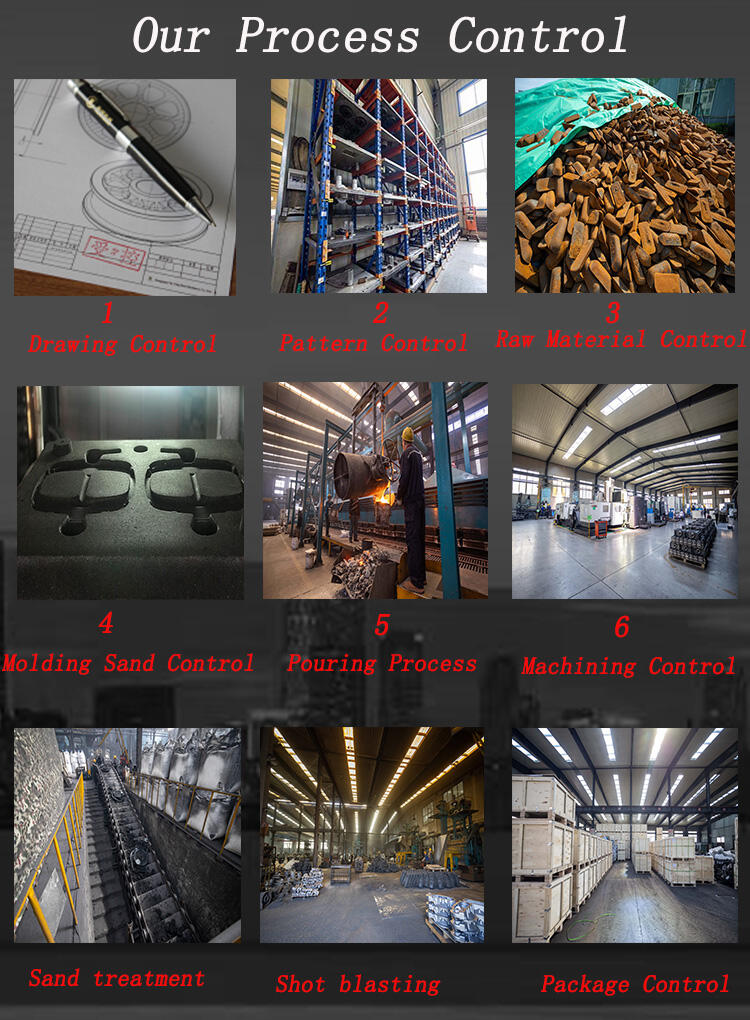

Controllo del Disegno → Controllo del Modello → Controllo delle Materie Prime → Controllo della Sabbia da Moulding → Controllo del Processo di Colata → Controllo di Fusione Grezza e Lavorazione Meccanica → Controllo di Altri Requisiti → Controllo di Imballaggio e Consegna

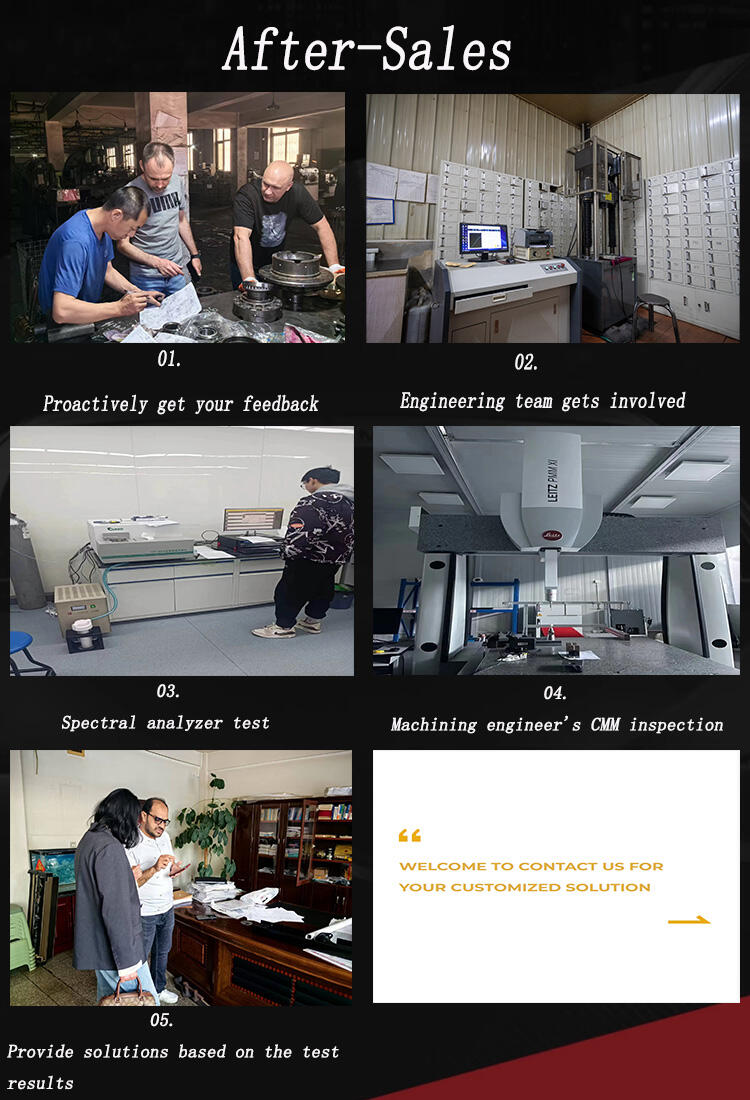

Post-vendita

Otteniamo proattivamente il tuo feedback → Il team di ingegneria si attiva → L'ingegnere metallurgico esegue analisi metallografiche e spettrografiche in base alle barre di prova disponibili in inventario → L'ingegnere di produzione effettua l'ispezione con macchina a coordinate (CMM) basata sui campioni disponibili in inventario → Forniamo soluzioni basate sui risultati dei test

risultati → Contattaci per ricevere una soluzione personalizzata

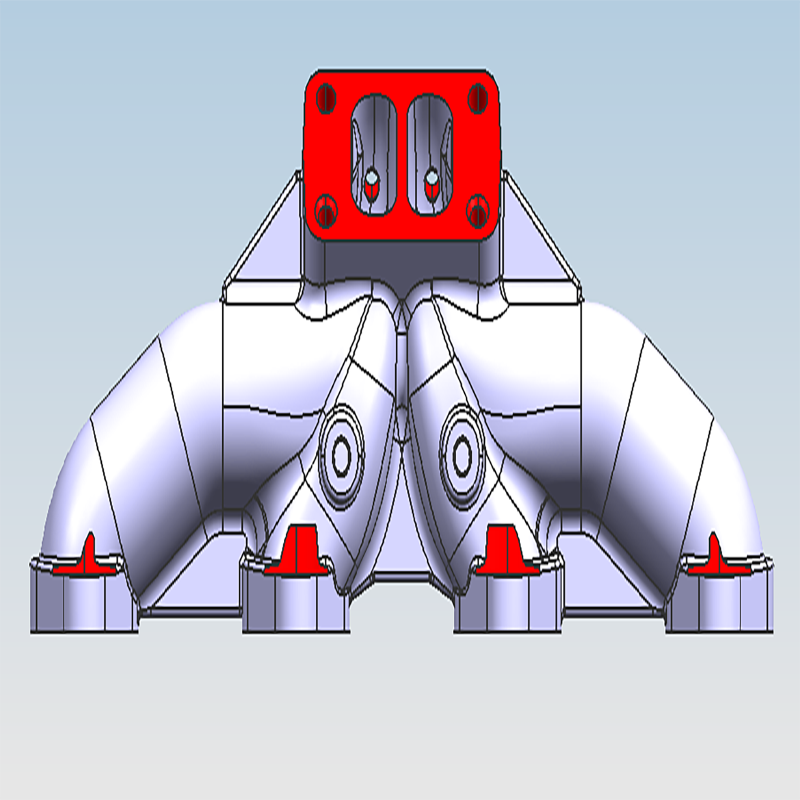

I progetti di processo derivano dai disegni tecnici

Utilizzando i progetti 3D forniti dai clienti, i nostri ingegneri sviluppano modelli di stampi precisi e svolgono analisi complete di simulazione della fusione prima della produzione

scanner 3D

Molti clienti distributori non dispongono di disegni 2D – Il team di ingegneria di Dandong Pengxin converte con competenza i campioni fisici in disegni tecnici precisi grazie a processi professionali di scansione e reverse engineering.

Stampo metallico per collettore di scarico, Fusione in sabbia rivestita

Esclusiva del settore: Soluzioni complete per collettori di scarico di lunghezza superiore a 1 metro invece che segmentate

assemblaggio.

Stampo metallico per collettore di scarico, Fusione in sabbia

il 90% dei nostri collettori di scarico viene prodotto in modo economico utilizzando macchine per la stampa, mantenendo bassi sia i costi degli stampi che di fusione.

Cassa Nucleo Collettore Scarico

Dandong Pengxin Machinery utilizza una tecnologia proprietaria di formatura a nucleo per produrre rapidamente gusci per fusioni e condurre test di colata dopo il completamento dello stampo, riducendo significativamente i tempi di consegna.

Macchina per Fusione a Cappello

Per affrontare i colli di bottiglia produttivi in cui ogni collettore occupa 2-3 macchine per la stampa, adottiamo soluzioni doppie: la nostra flotta di 16 macchine consente una pianificazione flessibile, mentre le fonderie partner forniscono capacità supplementare di produzione di nuclei in sabbia per ordini urgenti, garantendo tempi di consegna affidabili.

Fusione con sabbia rivestita

Dandong Pengxin è specializzata nella fusione di precisione con sabbia rivestita in resina, producendo oltre 50.000 tonnellate metriche annue di componenti automobilistici. Le nostre linee automatizzate producono fusioni di grado CT7-8 con pareti di 3-6 mm e finiture Ra 12-25μm. Certificata IATF 16949 e ISO9001

Macchine per la modellazione

Dispongono di quattro macchine per la fusione in sabbia di ghisa e due linee di stampaggio automatiche FBO III. La capacità produttiva è di 120 stampi all'ora, 9000 tonnellate all'anno. La dimensione degli stampi è di 605×505×200/200mm

Esposizione della forza produttiva della nostra fabbrica

Ricerca e Sviluppo

La nostra azienda possiede un Centro Tecnico a livello provinciale, oltre a un team di ricerca e sviluppo composto da 15 persone, con un'esperienza media di oltre 20 anni in Ricerca e Sviluppo. Possiamo aiutare i clienti a progettare gratuitamente in base alle loro esigenze, oppure produrre in base ai disegni o ai campioni

Capacità produttiva

Presso Pengxin-Casting, il controllo del processo inizia già nella fase di pianificazione e sviluppo dei prodotti. Supportiamo i nostri clienti nell'eseguire tutti i test e le ispezioni richiesti in laboratorio. È scontato che i nostri impianti siano certificati secondo gli standard ISO 9001 e IATF16949, in linea con un sistema di gestione della qualità validato. Poiché ci sforziamo di attuare la nostra politica dello zero errore, è possibile fare affidamento sulle seguenti misure di controllo del processo: Controllo dei Disegni → Controllo del Modello → Controllo delle Materie Prime → Controllo della Sabbia da Moulding → Controllo del Processo di Colata → Controllo del Grezzo e della Lavorazione Meccanica → Controllo di Altri Requisiti → Controllo dell’Imballaggio e della Consegna

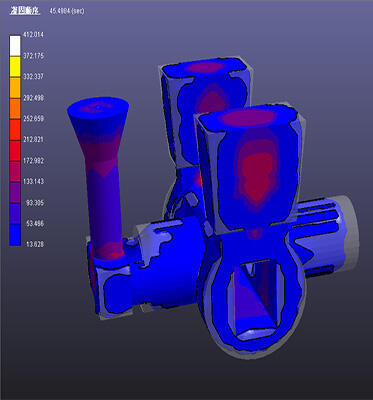

Controllo dei Modelli

Simuliamo il sistema di alimentazione per verificare il design del modello a partire dal processo di riempimento e dalla solidificazione del materiale; in questo modo possiamo ridurre il ciclo di sviluppo dello stampo, diminuire il numero di prove dello stampo e migliorare la qualità del prodotto. I software che utilizziamo includono

abaqus, Moldflow e Moldex 3D, simulano il sistema di alimentazione, riducono i difetti di fusione e migliorano l'efficienza

Controllo delle materie prime

Verifichiamo le proprietà chimiche all'arrivo del nuovo materiale grezzo

Controllo di lavorazione

Tutte le dimensioni misurate al 100% Analisi spettrale del materiale grezzo e rilevazione con raggi X Dimensioni critiche misurate con macchina a coordinate

Il nostro controllo di processo

Dandong Pengxin Foundry - Il tuo partner affidabile per soluzioni di fonderia. Sostenuti da oltre 67 anni di esperienza metallurgica, forniamo fusioni di precisione, tra cui collettori di scarico e carter turbo, grazie a tecnologie avanzate di sabbia rivestita con resina e di fusione a gravità. La nostra struttura con capacità di 50.000 tonnellate è dotata di macchine per la formatura automatizzate, produzione robotizzata di gusci e analisi spettrali per garantire la qualità, servendo clienti automobilistici e industriali a livello globale con produzioni certificate IATF 16949. Specializzati in fusioni a parete sottile (3-6 mm) con finiture Ra12-25μm, il nostro team di ingegneri sviluppa soluzioni ottimizzate, dal prototipo alla produzione di massa, supportati da progettazione interna degli stampi e sviluppo rapido dei campioni entro 15 giorni.