ISO9001 Skræddersyet Højtkvalitets Sandstøbning Impeller Tjenester ISO9001 Skræddersyet Højtkvalitets Sandstøbning Impeller Tjenester

- Oversigt

- Anbefalede produkter

Inden for fluid dynamik og pumpeindustrien repræsenterer ISO 9001-certificerede sandstøbningsløbehjulstjenester standarden for fremstilling af præcisionskomponenter, der opfylder strenge krav til kvalitetsstyring. Vores certificerede støberi specialiserer sig i produktion af højtydende løbehjul ved hjælp af avancerede sandstøbningsteknologier og sikrer derved konsekvent kvalitet og pålidelighed for kritiske pumpeapplikationer på tværs af flere sektorer.

Udvælgelse af fremragende materialer

Vores ISO 9001-certificerede impellerstøbningsydelser anvender højtkvalitets aluminiumslegeringer, sej jern og rustfrit stål, specielt udviklet til væskehåndtering. Aluminiumslegeringen A356-T6 giver et fremragende styrke-til-vægt-forhold med en trækstyrke på op til 45.000 psi samt fremragende korrosionsbestandighed. Til krævende applikationer anvender vi CF8M rustfrit stål (svarende til 316) med overlegen korrosionsbestandighed i aggressive medier og en trækstyrke på over 70.000 psi. Sejt jern i kvalitet 65-45-12 sikrer forbedret slagstyrke med en brudforlængelse op til 12 %, hvilket gør det ideelt til tunge pumpeoperationer. Alle materialer gennemgår omfattende certificering og sporbarhedsprocedurer i overensstemmelse med ISO 9001-kvalitetsstyringsstandarder.

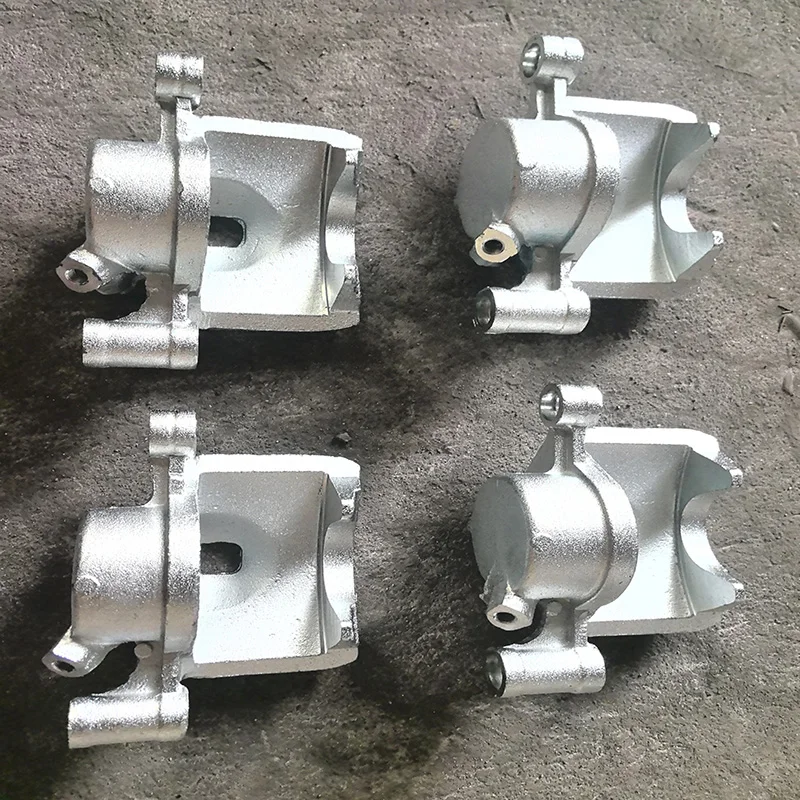

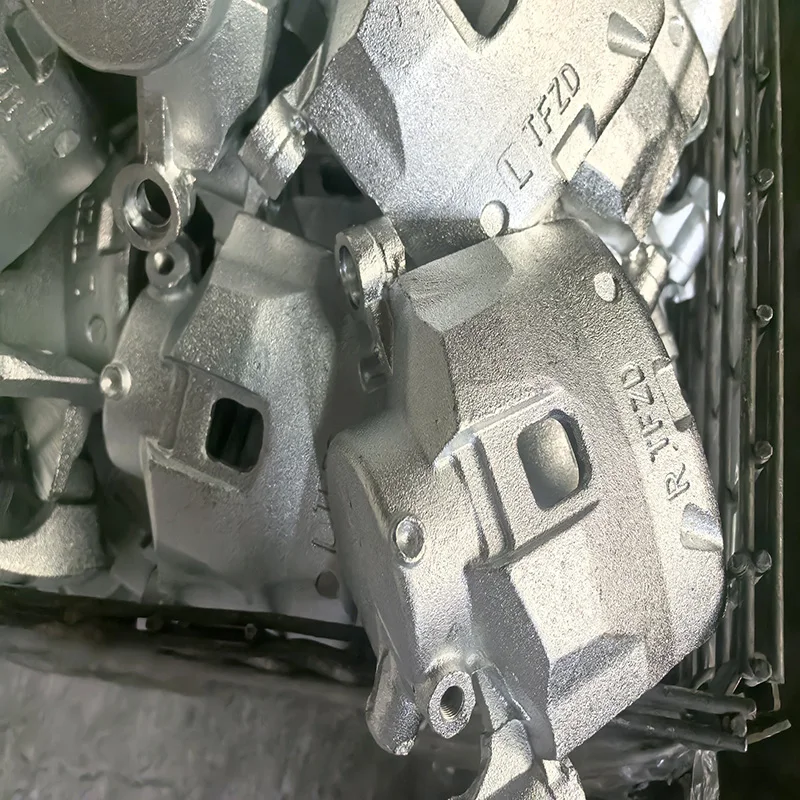

Præcisionsstøbningsteknologi i sand

Vores certificerede sandstøbningsprocesser integrerer nyeste teknologi inden for støberiteknik og streng kvalitetskontrol:

Avancerede formningsystemer

Harpiksbundet formsstøbning ved anvendelse af furan- og fenolharpsystemer sikrer dimensionel nøjagtighed og overlegen overfladekvalitet

Automatiske formstøbningslinjer med en produktionskapacitet på over 120 former i timen sikrer konsekvent kvalitet gennem alle produktionsbatche

CAD-optimeret mønsterdesign inkluderer korrekte udklækningsvinkler, bearbejdningstillæg og strategisk gjæringsudformning for optimal metalstrøm

Overvågning i realtid registrerer kritiske parametre såsom sandsammensætning, fugtindhold og binderforhold

Kvalitetskontrolleret produktion

Spektrografisk analyse bekræfter den kemiske sammensætning for hver smelte, hvorved overholdelse af materialekravene sikres

Styringssystemer til hældning holder optimal metallisk temperatur mellem 680-750 °C afhængigt af legeringskrav

Strategiske køleprotokoller udvikler optimal mikrostruktur og mekaniske egenskaber gennem kontrolleret stivning

Omfattende dokumentation sikrer fuld sporbarhed fra råmateriale til færdig impeller

Forbedret ydelsesevne

ISO 9001-certificerede impeller fremstillet gennem vores processer leverer:

Optimeret hydraulisk effektivitet: Præcisionsstøbte vane profiler og overfladeafslutninger (Ra 125-250 μin) minimerer turbulens og maksimerer pumpeeffektiviteten

Overlegen mekanisk styrke: Modstår centrifugalkræfter og hydrauliske belastninger ved højhastighedsdrift

Udmærket korrosionsbestandighed: Bevarer strukturel integritet ved håndtering af vand, kemikalier og slidende slam

Reduceret kavitationspotentiale: Afbalanceret design og præcist støbning minimerer overfladefejl, der udløser kavitation

Lang levetid: Holdbar konstruktion modstår slid i slidende anvendelser og forlænger vedligeholdelsesintervaller

Kompleks kvalitetsikring

Vores ISO 9001-certificerede kvalitetsstyringssystem sikrer:

Førsteartikelinspektion: Omfattende dimensionel verifikation ved hjælp af koordinatmålemaskiner for alle kritiske funktioner

Ikke-destruktiv testning: Radiografisk og flydende penetrantinspektion, der opdager indre og overfladefejl

Validering af mekaniske egenskaber: Trækhårdhedstest, hårdhedsverifikation og mikrostrukturanalyse i overensstemmelse med ASTM-standarder

Dynamisk afbalancering: Præcisionsafbalancering i henhold til ISO 1940 G6.3-standard eller bedre for sikring af jævn drift ved nominelle hastigheder

Ydelsestest: Verifikation af hydraulisk effektivitet og analyse af flowegenskaber

Teknisk applikations ekspertise

Vores certificerede impellerstøbetjenester understøtter mange industrielle anvendelser:

Behandling af vand og spildevand

Centrifugalpumpeimpeller til rensning af vanddistribution og kloaksystemer

Rør- og omrørerimpeller, der kræver korrosionsbestandighed og mekanisk holdbarhed

Aerationssystemkomponenter, der kræver præcis hydraulisk ydeevne og pålidelighed

Industrielle procesapplikationer

Kemiske procespumper til håndtering af ætsende væsker og opløsningsmidler ved varierende temperaturer

Slammpumpeimpeller med slidstærke design til håndtering af abrasive materialer

Kølevandsomløbssystemer, der kræver effektiv drift og korrosionsbestandighed

Særlige sektorkrav

Marine og offshore-anvendelser, der kræver fremragende korrosionsbeskyttelse i saltvandsmiljøer

Brandsikringssystemer, der kræver pålidelighed og konstant ydeevne i nødssituationer

Fødevare- og farmaceutisk procesindustri, der kræver sanitære design og materialecertificeringer

Fordele ved OEM-samarbejde

Vores ISO 9001-certificering giver kunderne betydelige fordele:

Konsekvent kvalitetssikring: Dokumenterede processer sikrer gentagelig kvalitet i alle produktionsbatche

Teknisk dokumentation: Komplette certificeringspakker inklusive materiale-rapporter, inspektionsprotokoller og overholdelsesdokumentation

Kontinuerlig forbedring: Regelmæssige procesrevisioner og kvalitetsgennemgange driver løbende forbedringer af produkter og processer

Leveringskædens pålidelighed: Certificeret kvalitetsstyring sikrer pålidelig levering og konsekvent komponentydelse

Materiale |

stål, rostfrit stål, aluminium, jern, kulstofstål, kobber, brønse, alloy, etc. |

Tykkelse |

0,1mm til 12mm, som du anmoder om |

Størrelser |

1) Efter kundens tegninger 2) I overensstemmelse med kundens eksemplarer |

Overfladebehandling |

Anodering, galvaniseret, zink, nickel, chrome platering, pulverkoting, maleri, etc. |

Tegningsformat |

DWG, DXF, STEP, STP, STL, AI, PDF, JPG, Skitse. |

Emballage |

Polybag+Carton box+Trækasse/Palle, i overensstemmelse med kundens anmodning |

Forsendelse |

1) Ved kurier, som DHL, TNT, Fedex osv., normalt 5-7 dage til ankomst |

2) Ved luftfart til lufthavn, normalt 3-4 dage til ankomst |

|

3) Ved havn, normalt 15-30 dage til ankomst |

|

Leveringstid |

afhængigt af mængderne, normalt omkring 20 dage. |

Betalingsbetingelse |

T/T, Paypal, Handelsgaranti |

Certifikat |

ISO |

Logo Service |

leveret |

Anvendelse |

brugt i stor udstrækning inden for byggeri, industri og bilindustri. |