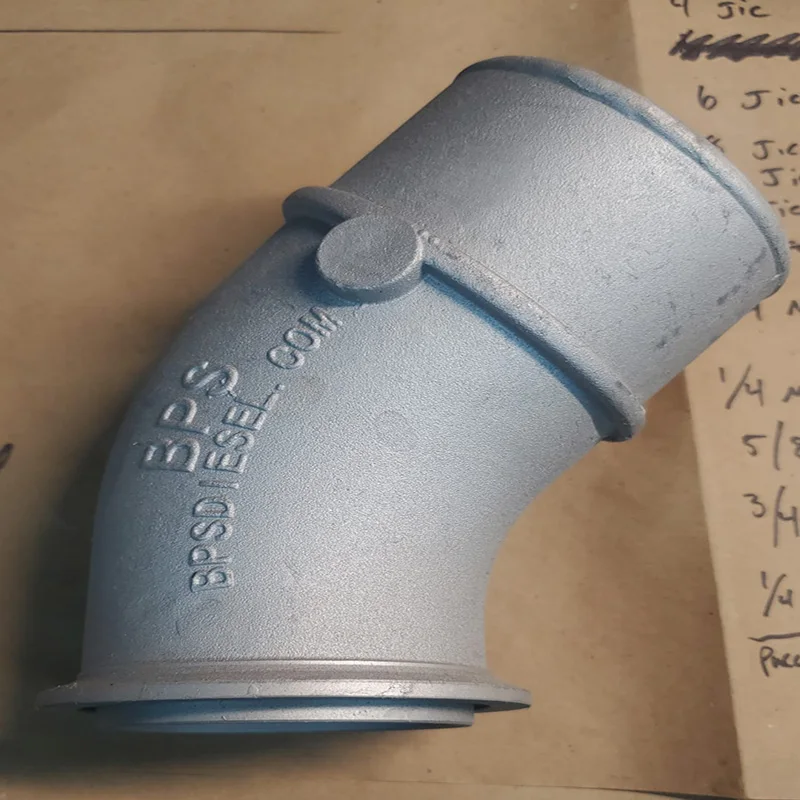

Truck Parts Auto Part Aluminum Alloy Steel Gravity Casting with Sand Blasting Casting Services Product

- Overview

- Recommended Products

Our specialized gravity casting services with integrated sand blasting treatment provide premium aluminum alloy and steel components for truck and automotive applications. This comprehensive manufacturing solution delivers durable, high-performance parts capable of withstanding the rigorous demands of commercial vehicle operations while maintaining precision and reliability.

Material Engineering Excellence

We utilize advanced materials specifically engineered for automotive applications:

A356-T6 Aluminum: Optimal strength-to-weight ratio with excellent corrosion resistance

A380 Aluminum: Superior fluidity characteristics for complex geometries

Ductile Iron GGG40/50: Enhanced impact resistance and load-bearing capacity

Carbon Steel 1045/4140: High strength and wear resistance for structural components

Special Alloy Steels: Custom formulations for specific performance requirements

Integrated Manufacturing Process

Our comprehensive production methodology ensures superior quality:

Gravity Casting Phase

Mold Design: CAD-engineered permanent molds with optimized gating systems

Metal Preparation: Controlled atmosphere melting with precise temperature management

Pouring Process: Tilt pouring technology for laminar metal flow

Solidification Control: Managed cooling rates for optimal microstructure

Heat Treatment: Solution annealing and aging for enhanced properties

Surface Treatment Technology

Automated sand blasting with controlled media selection

Surface profile optimization for coating adhesion

Uniform texture achievement across all surfaces

Comprehensive cleaning and preparation

Quality verification of treated surfaces

Performance Characteristics

Mechanical Strength: 250-500 MPa tensile strength range

Surface Durability: Enhanced wear resistance through surface treatment

Corrosion Resistance: Superior protection against environmental exposure

Dimensional Stability: Maintains precision under thermal cycling

Weight Optimization: Significant weight reduction compared to conventional parts

Fatigue Resistance: Excellent performance under dynamic loading conditions

Quality Assurance Protocol

Material certification and traceability

Non-destructive testing implementation

Dimensional validation with CMM systems

Surface roughness and profile measurement

Mechanical property testing

Final comprehensive inspection

Truck Applications

Engine Components: Bracket supports and mounting systems

Chassis Parts: Structural reinforcements and connection elements

Transmission Systems: Housing components and mounting brackets

Suspension Components: Arms, brackets, and structural elements

Braking Systems: Caliper supports and mounting hardware

Technical Advantages

Enhanced surface preparation for superior coating adhesion

Improved fatigue strength through optimized microstructure

Reduced maintenance requirements through enhanced durability

Excellent impact resistance for heavy-duty applications

Superior corrosion protection in harsh environments

Consistent quality across production batches

Customization Capabilities

Complete design for manufacturability analysis

Prototype development and validation services

Volume production from small batches to mass production

Multiple surface treatment options

Custom packaging and logistics solutions

Technical support and engineering consultation

Our aluminum alloy and steel gravity casting services with integrated sand blasting provide truck manufacturers with components that deliver exceptional performance, durability, and reliability. Through advanced manufacturing techniques and rigorous quality control, we ensure every part meets the stringent requirements of the automotive industry while providing cost-effective solutions for both OEM and aftermarket applications.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |