Professional High-Precision CNC Machining Auto Parts and Motor Spare Parts Casting Services Product Category

- Overview

- Recommended Products

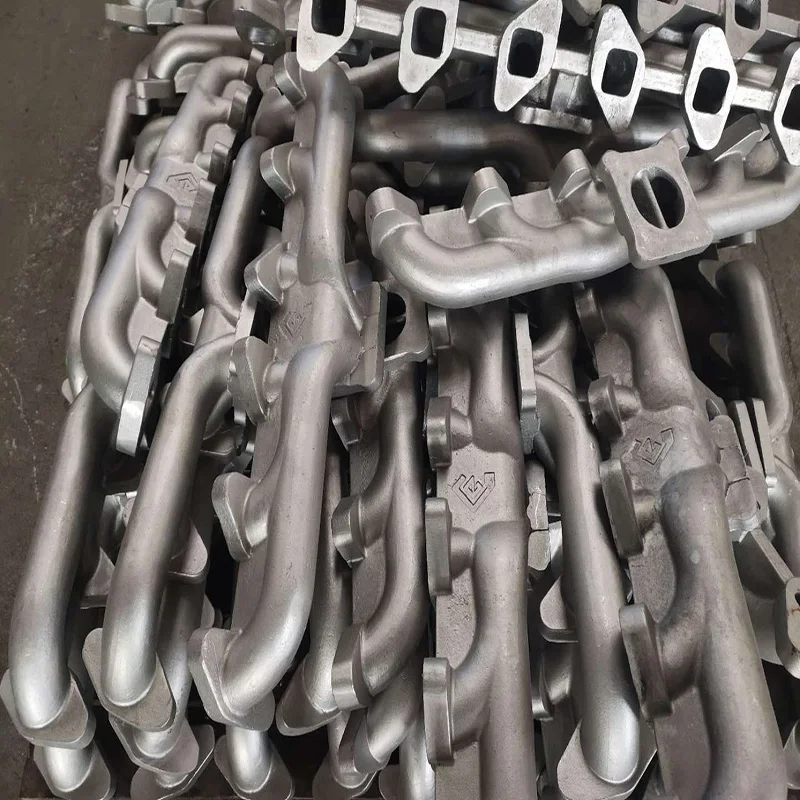

Our professional high-precision CNC machining services specialize in manufacturing critical auto parts and motor spare parts through integrated casting and precision machining processes. We deliver components that meet the stringent requirements of modern automotive and motor industries, combining superior materials with advanced manufacturing technologies.

Material Engineering Excellence

We utilize premium materials specifically engineered for automotive and motor applications:

Aluminum Alloys: A380, ADC12 for lightweight structural components

Ductile Iron: GGG40, GGG50 for high-strength engine components

Stainless Steel: 304, 316 for corrosion-resistant applications

Carbon Steel: 1045, 4140 for high-wear resistance parts

Brass and Bronze: For electrical and bearing applications

Special Alloys: Custom formulations for specific performance requirements

Integrated Manufacturing Technology

Our comprehensive production process combines casting with precision machining:

Precision Casting Phase

Die Casting Process: High-pressure automation for aluminum components

Sand Casting: Resin-bonded molds for iron and steel parts

Investment Casting: Precision method for complex geometries

Quality Verification: Initial dimensional and material inspection

CNC Machining Operations

5-axis simultaneous machining centers

CNC turning with live tooling capabilities

High-speed milling for complex contours

Precision grinding for critical surfaces

Automated quality control systems

Performance Characteristics

Dimensional Precision: ±0.01mm tolerance capability

Surface Quality: Ra 0.8-3.2μm achievable finishes

Mechanical Strength: Optimized for specific load conditions

Thermal Resistance: Stable performance under temperature cycling

Wear Resistance: Enhanced durability for moving components

Corrosion Protection: Suitable for various operating environments

Quality Assurance Protocol

IATF 16949 quality management system

Material certification and traceability

Statistical process control implementation

CMM dimensional verification

Surface roughness and hardness testing

Performance validation under simulated conditions

Automotive Applications

Engine Components: Cylinder heads, blocks, and manifolds

Transmission Systems: Gearbox housings and internal components

Suspension Parts: Control arms and steering components

Braking Systems: Calipers and mounting brackets

Electrical Systems: Sensor housings and connectors

Motor Spare Parts Category

Housing Components: End shields and motor frames

Rotor Assemblies: Core components and shaft connections

Bearing Systems: Housings and retention components

Cooling Systems: Fan shrouds and heat dissipation parts

Mounting Solutions: Brackets and installation hardware

Technical Advantages

Reduced weight with maintained strength

Improved heat dissipation characteristics

Enhanced corrosion resistance

Superior dimensional stability

Excellent machinability for secondary operations

Consistent batch-to-batch quality

Customization Capabilities

Prototype development within 15 working days

Design for manufacturability optimization

Small batch production from 50 pieces

Volume manufacturing up to 100,000+ annually

Just-in-time delivery programs

Comprehensive technical support

Our professional high-precision CNC machining and casting services provide automotive and motor industries with reliable, high-performance components that meet the evolving demands of modern transportation and industrial applications. Through continuous process improvement and technological innovation, we ensure our clients receive components that deliver exceptional performance and longevity.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |