In the powertrain systems of industrial machinery and automotive applications, the transmission housing serves as the critical structural component that ensures proper gear alignment and protects internal mechanisms. Our OEM gray cast iron sand casting service delivers transmission housings that combine exceptional durability with cost-effective manufacturing. These components provide the foundation for reliable power transmission across various industries, offering superior vibration damping and long-term dimensional stability under continuous operational stress.

Material Specifications and Performance Characteristics

We utilize high-grade gray cast iron (G3000-G3500) specifically engineered for transmission applications. This material delivers excellent compressive strength (900-1100 MPa) and outstanding vibration damping capacity – approximately 5-10 times greater than steel – which is crucial for reducing noise and minimizing gear resonance. The flake graphite microstructure provides natural lubricity and wear resistance, while maintaining good thermal conductivity for effective heat dissipation. Our G3500 grade offers tensile strength of 350 MPa minimum with Brinell hardness of 200-250, ensuring reliable performance under heavy torque loads and shock conditions encountered in power transmission systems.

Precision Sand Casting Manufacturing Process

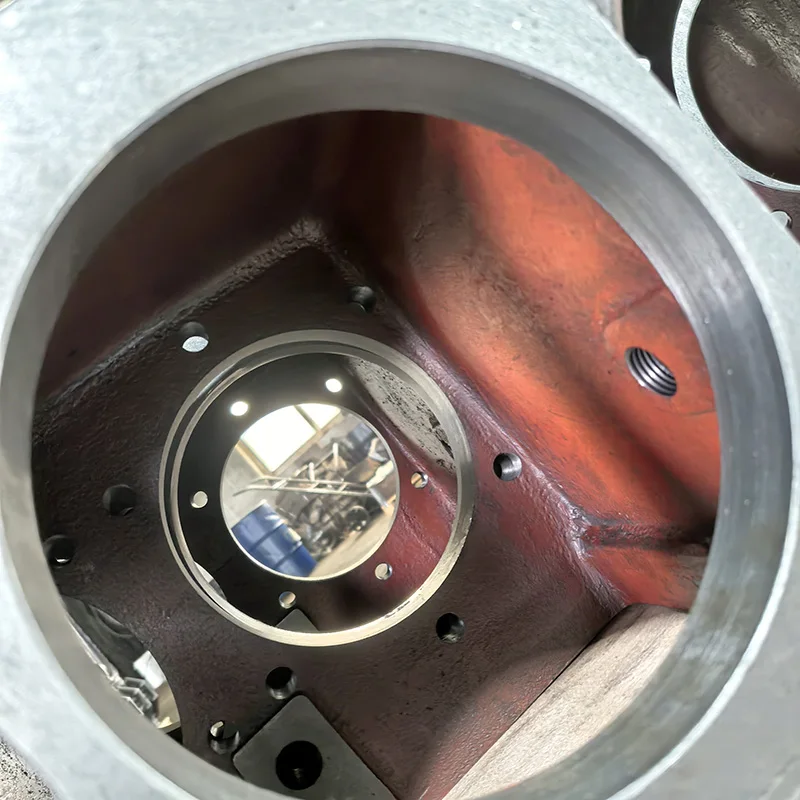

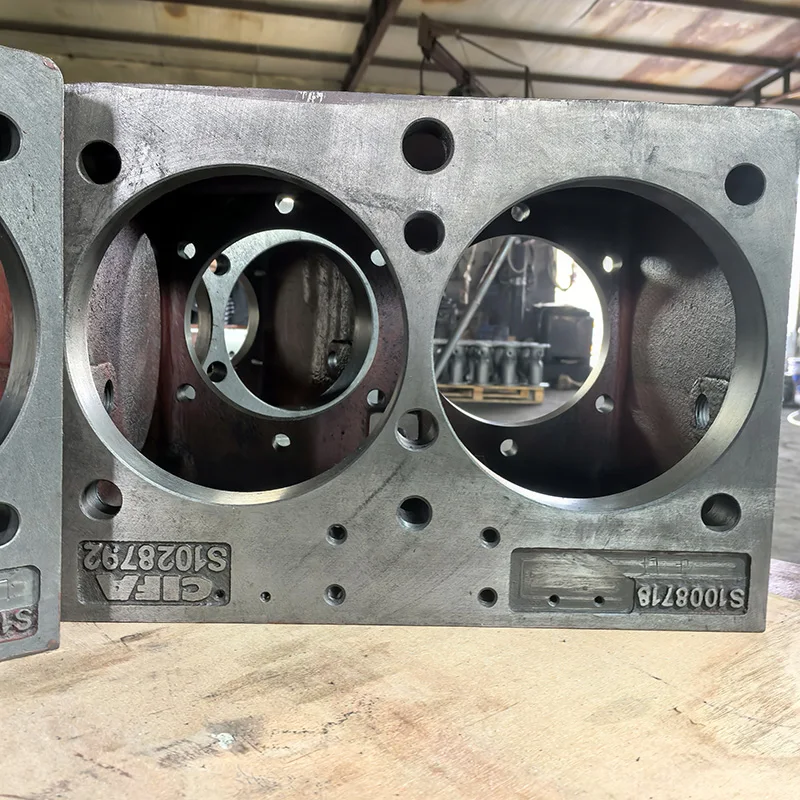

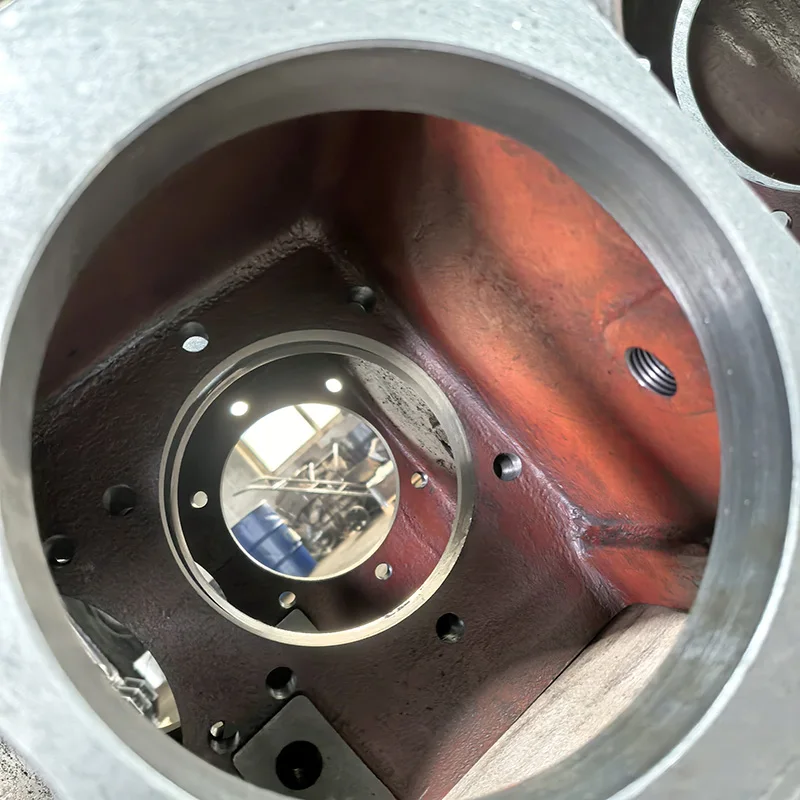

Our manufacturing employs advanced green sand casting technology with automated molding lines that maintain consistent wall thickness and dimensional repeatability. The process begins with precision pattern equipment designed to achieve optimal gating and feeding systems specific to transmission housing geometry. Controlled pouring parameters and real-time thermal monitoring guarantee sound castings free from shrinkage defects and inclusions. Each housing undergoes precision machining on CNC boring mills and machining centers, maintaining bearing bore tolerances within ±0.001 inches and gear mounting surface flatness within 0.001 inches per foot. The process includes comprehensive quality verification through dimensional inspection, ultrasonic testing, and mechanical property validation.

Comprehensive Industrial Applications

Our OEM transmission housings serve vital functions across multiple sectors. The automotive industry utilizes our components for manual and automatic transmission cases, transfer cases, and gearbox assemblies. Agricultural machinery manufacturers specify our housings for tractor transmissions, combine harvester gearboxes, and implement drives. Industrial applications include power transmission systems for conveyor drives, pump transmissions, and heavy equipment gearboxes. The design flexibility of sand casting accommodates complex internal passages, mounting bosses, and reinforcement ribs that would be challenging to produce through other manufacturing methods.

Partner with our foundry for OEM gray cast iron transmission housings that combine manufacturing expertise with application-specific engineering. Our comprehensive approach from design assistance to finished machining ensures components that enhance transmission reliability, reduce noise vibration harshness, and provide long-term value across diverse powertrain applications, supported by stringent quality control and production consistency.