- Overview

- Recommended Products

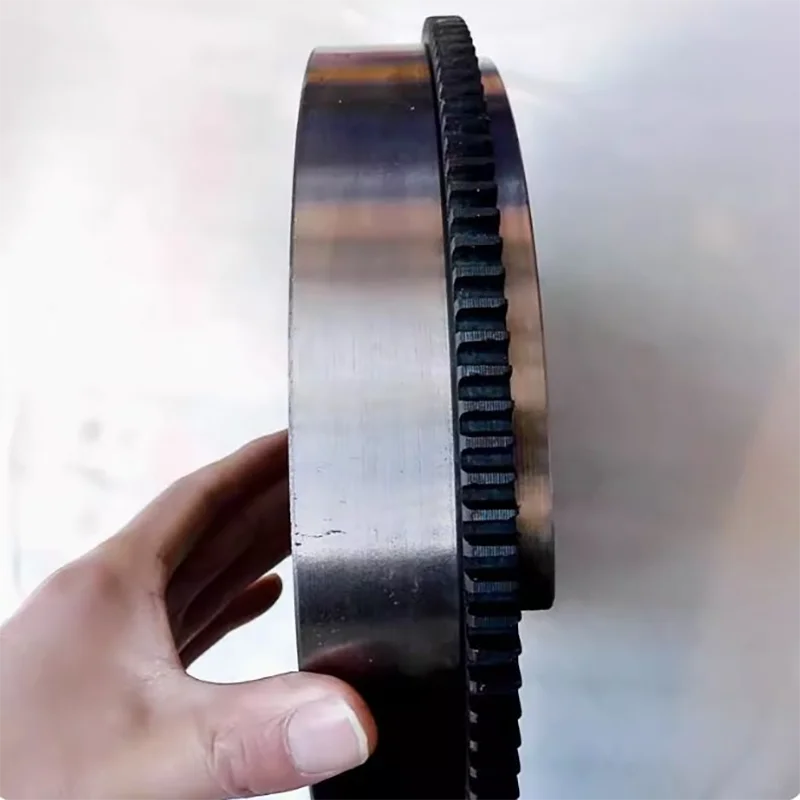

For owners and technicians maintaining TOYOTA vehicles equipped with the robust 15B diesel engine, the flywheel assembly is a critical drivetrain component that ensures reliable engine starting and smooth power transfer. The High Quality 15B Flywheel Assembly, bearing part number 13450-58070, is engineered as a direct OEM replacement, guaranteeing perfect fitment, durable performance, and long-term reliability for commercial and utility vehicles.

Premium Material for Durability and Performance

This flywheel assembly is manufactured from high-grade cast iron, specifically chosen for its exceptional strength, superior wear resistance, and excellent vibration-damping properties. The material's high thermal capacity prevents warping and heat spotting caused by repeated clutch engagement and disengagement. This ensures a consistent friction surface, promoting smooth clutch operation and preventing chatter, which is essential for the demanding operational cycles of diesel engines in vehicles like the Toyota Coaster or Dyna truck.

Precision Engineering and Balanced Manufacturing

The production of this flywheel involves a precision casting process to create a dense, homogeneous structure, followed by meticulous CNC machining. Critical surfaces, including the friction face and mounting flange, are machined to exact OEM tolerances to ensure perfect flatness and runout. This guarantees optimal contact with the clutch disc and correct alignment with the crankshaft. A core part of the manufacturing process is dynamic balancing, where the assembly is balanced to a high standard to eliminate vibrations that can damage transmission bearings and cause driveline noise, ensuring smooth engine operation.

Direct Application for Reliable Operation

The 15B Flywheel Assembly (13450-58070) is a direct-fit component designed for specific TOYOTA models powered by the 15B diesel engine. It is an integral part of the clutch system, providing the friction surface for the clutch disc and connecting the engine's power to the transmission input shaft. This assembly is the definitive solution for repairs necessitated by a worn, cracked, or heat-damaged original flywheel. Its reliable performance is crucial for smooth vehicle operation, especially in stop-start driving conditions and under heavy load.

Choose this high-quality flywheel assembly to restore the integrity and performance of your TOYOTA's drivetrain. It delivers the durability, precision balancing, and exact fit required for dependable service, minimizing downtime and ensuring driver comfort.

About Us

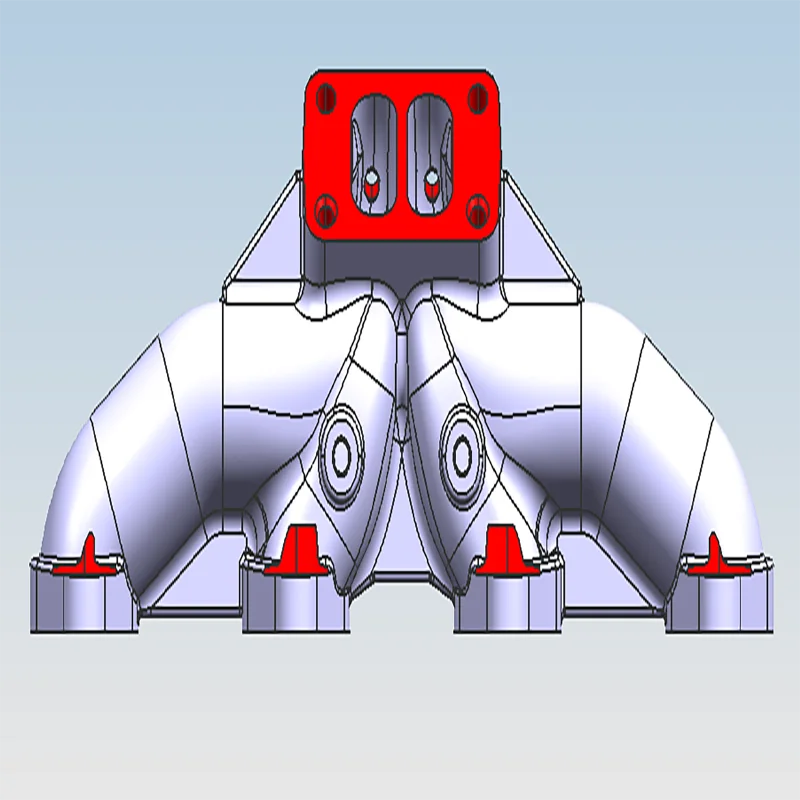

Why are we called OEM experts in Exhaust Manifolds |

We develop over 100 different types of exhaust manifolds every year |

||||||

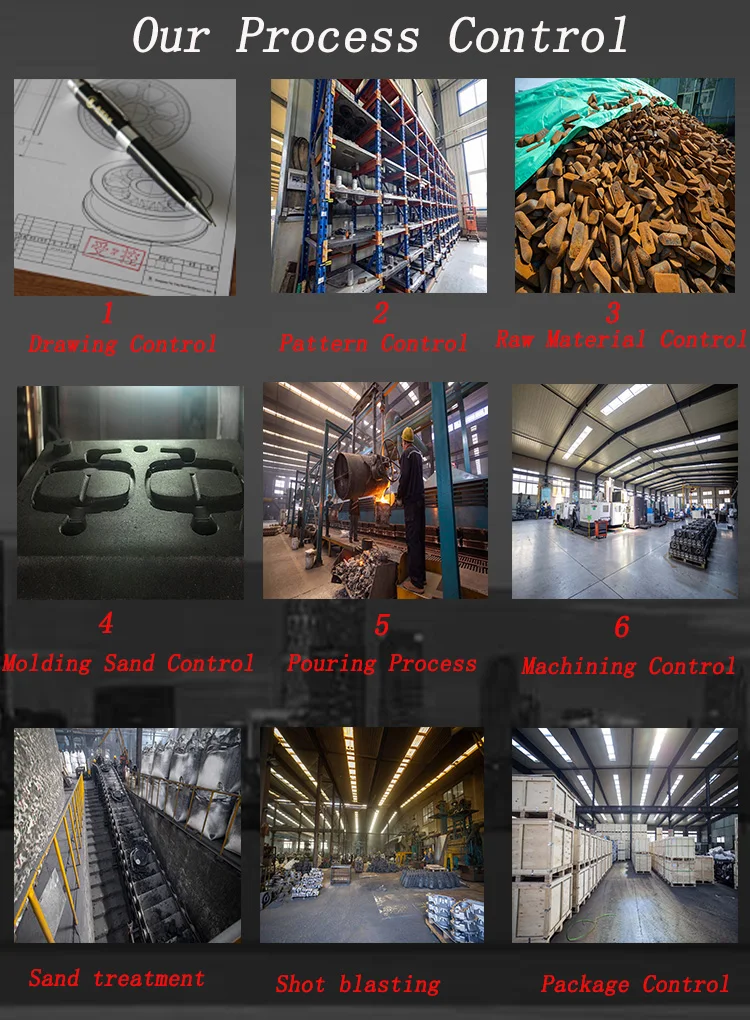

Dandong Pengxin Production Process for Exhaust Manifold |

Drawing Preparation: The Foundation of Precision,3D Scanning & Drafting: Our professional engineers use advanced scanners to convert samples into 2D/3D drawings (7–10 days). |

||||||

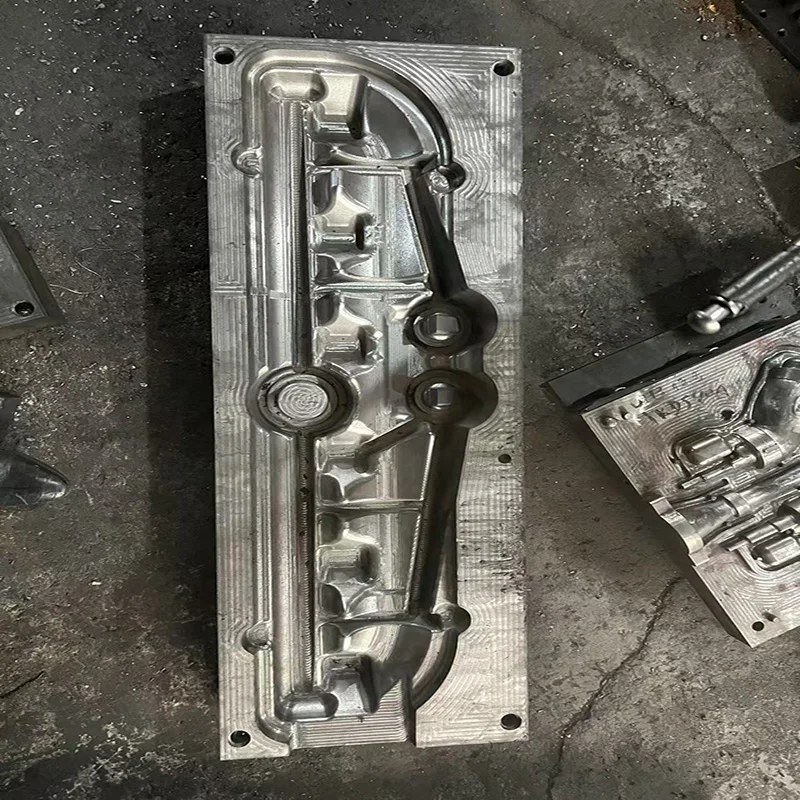

Pattern & Sample Development: Where Time Invested Pays Off |

Complexity: Exhaust manifolds often require 3–5 sets of metal patterns (vs. 1 set for simpler castings).Lead Time: 35–40 days for multi-cavity patterns; 25–30 days for simpler designs. |

||||||

Initial Orders & Batch Production: Scaling Responsibly |

Machine Allocation: One manifold order may occupy 2–3 molding machines. Our 16-machine facility prioritizes urgent orders and collaborates with partner foundries for auxiliary cores. |

||||||

How Investors Can Mitigate Delays |

Allocate 8–12 weeks for pattern/sample development. Compressing this risks quality failures. First batches take 20–30% longer due to process fine-tuning. Post-approval, lead times stabilize. |

||||||

Pre-sales

On Sale

After-Sales

results→Welcome to contact us for your customized solution.

How did Dandong Pengxin Become a Top Manufacturer of Exhaust Manifold

Process designs derive from engineering drawings

3D scanners

Metal Mold for Exhuast Manifold,Coated sand casting

Metal Mold for Exhaust Manifold,Sand Casting

Exhaust Manifold Core Box

Shell Molding Machine

Coated sand casting

Molding Machines

R&D

Production Capacity

Pattern Control

Abaqus,Moldflow and Moldex 3D, simulate feeding system, reduce casting defects and improve efficiency.

Raw Material Control

Machining Control