- Overview

- Recommended Products

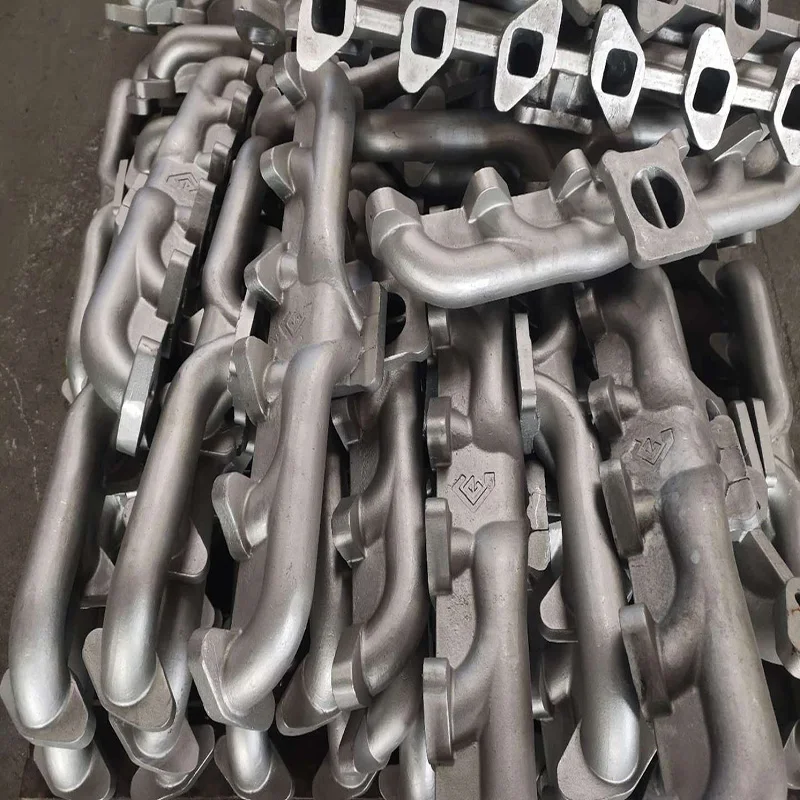

As a premium supplier of high-accuracy lost wax investment casting services, we specialize in producing complex stainless steel components with exceptional dimensional precision and superior surface quality. Our advanced manufacturing capabilities enable us to deliver parts that meet the most stringent requirements for industries where reliability and precision are paramount.

Material Expertise

We process comprehensive stainless steel grades for diverse applications:

304/L Stainless Steel: Excellent general-purpose corrosion resistance

316/L Stainless Steel: Superior chloride resistance with molybdenum enhancement

17-4PH Stainless: Precipitation-hardening for high-strength applications

420 Stainless Steel: Martensitic grade for enhanced hardness and wear resistance

Duplex Stainless: Combined austenitic-ferritic structure for extreme environments

Advanced Lost Wax Process

Our investment casting methodology ensures unmatched precision:

Pattern Creation

Injection Molding: Precision wax patterns with aluminum tooling

Assembly Engineering: Optimized gating and runner systems

Quality Verification: Dimensional inspection of wax assemblies

Shell Building Process

Primary ceramic coating with zirconia base

Secondary backup coats with fused silica

Controlled drying environment maintenance

Shell hardening and strengthening

Casting Operation

Controlled atmosphere melting

Precision pouring temperature control

Automated dewaxing systems

Controlled solidification management

Performance Characteristics

Dimensional Accuracy: CT4-6 tolerance levels achievable

Surface Finish: Ra 1.6-3.2μm standard, Ra 0.8μm with special processing

Mechanical Properties: Tensile strength 515-795 MPa depending on grade

Corrosion Resistance: Excellent performance in harsh environments

Temperature Capability: Continuous service to 800°C for most grades

Minimum Wall Thickness: 0.75mm achievable for complex geometries

Quality Assurance Systems

Spectrochemical material analysis

X-ray and fluorescent penetrant inspection

CMM dimensional verification

Mechanical property testing

Pressure and leak testing

Microstructure examination

Industrial Applications

Aerospace Components: Turbine blades, engine parts, and structural elements

Medical Instruments: Surgical tools, implantable devices, and equipment parts

Food Processing: SANITARY valves, fittings, and processing components

Marine Equipment: Seawater-resistant components and marine hardware

Chemical Processing: Corrosion-resistant valves, pumps, and vessels

Technical Advantages

Complex geometry capability without additional assembly

Superior surface quality reducing finishing costs

Excellent dimensional repeatability across production runs

Material integrity with controlled grain structure

Design flexibility for integrated features

Cost-effective for medium to high complexity parts

Premium Supplier Differentiators

Advanced simulation software for process optimization

Automated shell building systems for consistency

Climate-controlled production environment

Comprehensive documentation and traceability

Technical support throughout product lifecycle

Continuous process improvement commitment

Our high-accuracy lost wax investment casting services represent the pinnacle of stainless steel component manufacturing. Through relentless focus on quality, precision, and customer service, we deliver components that exceed expectations while providing technical excellence and reliable performance in the most demanding applications.

Our Services |

CNC Precision Milling Machining,CNC Precision Turning Machining, Rapid Prototyping Plastic Injection Mould Metal Stamping, Die Casting, Silicone And Rubber Mould, Aluminum Extrusion, Mould Fabrication,etc |

Material |

Aluminum Alloy:5052/6061/6063/7075 etc Brass Alloy: 3602/2604/h59/h62/etc Stainless Steel Alloy: 303/304/316/412/etc Steel Alloy: Carbon/Die Steel/etc Other Special Materials: Lucite/Nylon/Bakelite/etc Plastic, Wood, Silicone, Rubber,Or as per the customers’ requirements |

Surface Treatment |

Anodizing, Sandblasting, Painting, Powder coating, Electroplating, Silk Printing, Brushing, Polishing, Laser Engraving... |

Drawing Format |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl,etc |

Service Project |

To provide project design, production and technical service, mould development and fabrication, etc |

Testing Machine |

Digital Height Gauge, caliper, Three Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

Quality Assurance |

ISO9001:2015 Certified TUV |

Packing |

Foam, Carton, Wooden boxes, or as per the customer’s requirements |

Deliver |

DHL, FEDEX, UPS, TNT, EMS, SF Or according to customers′ requirement |