- Overview

- Recommended Products

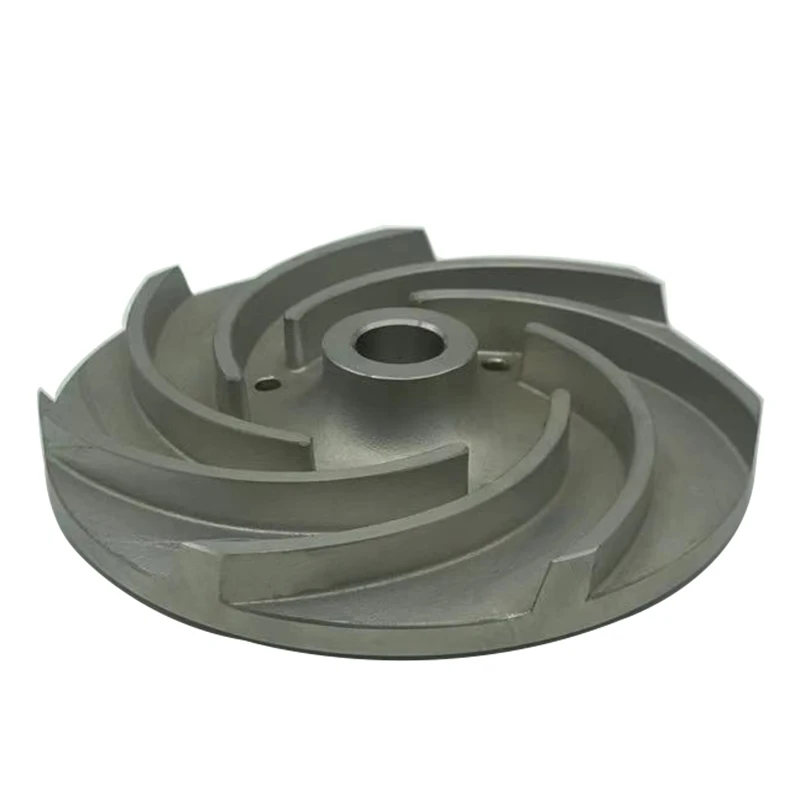

In sectors where failure is not an option, the combination of a superior material and a precision-driven process is critical. As a specialized manufacturer, we focus on producing customized components using AISI 316 stainless steel via the precision investment casting method. This synergy delivers unparalleled performance for the most demanding applications, offering design freedom, corrosion resistance, and exceptional dimensional accuracy in both prototype and mass production volumes.

Mastering the AISI 316 Stainless Steel Alloy

AISI 316 is an austenitic stainless steel renowned for its enhanced performance, primarily due to the addition of 2-3% Molybdenum. This key alloying element significantly boosts its resistance to pitting and crevice corrosion in chloride-laden environments. Our controlled melting and casting practices ensure the final cast alloy (equivalent to ASTM A743/CF8M) maintains its optimal chemical composition, providing excellent strength and stability from cryogenic temperatures up to approximately 800°C.

The Precision Investment Casting Advantage

Our core expertise lies in the investment casting (lost-wax) process, ideal for creating complex, intricate, and high-tolerance parts that are difficult or costly to machine from solid bar stock.

Tooling & Pattern Creation: We produce custom, injection-molded wax patterns using dies designed from your 3D CAD models, enabling limitless design customization.

Shell Building: Each wax pattern assembly is repeatedly dipped in ceramic slurries and stuccoed to build a robust, refractory mold.

Dewaxing & Casting: The mold is heated to remove the wax, and molten AISI 316 stainless steel is poured into the resulting cavity.

Finishing & Processing: The ceramic shell is removed, and castings are separated. We then offer a full range of secondary operations, including heat treatment, precision CNC machining of critical features, and surface finishing like passivation or electropolishing.

Key Properties and Performance Benefits

Superior Corrosion Resistance: Excellent resistance to a wide range of chemicals, seawater, and acidic conditions.

High Strength and Toughness: Maintains good mechanical properties at both low and high temperatures.

Excellent Surface Finish and Dimensional Accuracy: Achieves tight tolerances (ISO CT6-CT7) and smooth surfaces, reducing finishing costs.

Design Freedom: Creates complex internal passages, thin walls, and integrated geometries without the constraints of traditional machining.

Diverse Industrial Applications

Our custom AISI 316 investment castings are vital in numerous industries, including:

Marine & Offshore: Pump impellers, valve trim, propeller blades, and fittings.

Chemical & Pharmaceutical Processing: Reactor vessels, mixer shafts, and valve bodies.

Food & Beverage Equipment: Processing machinery parts requiring high hygiene and corrosion resistance.

Medical & Surgical Instruments: Complex, biocompatible instrument housings and components.

Oil & Gas: Critical components for downhole and subsea applications.

Leverage our expertise to produce high-integrity, custom AISI 316 components that enhance your equipment's reliability and service life. Contact us today to initiate a design review and receive a comprehensive quote for your project.

Our Services |

CNC Precision Milling Machining,CNC Precision Turning Machining, Rapid Prototyping Plastic Injection Mould Metal Stamping, Die Casting, Silicone And Rubber Mould, Aluminum Extrusion, Mould Fabrication,etc |

Material |

Aluminum Alloy:5052/6061/6063/7075 etc Brass Alloy: 3602/2604/h59/h62/etc Stainless Steel Alloy: 303/304/316/412/etc Steel Alloy: Carbon/Die Steel/etc Other Special Materials: Lucite/Nylon/Bakelite/etc Plastic, Wood, Silicone, Rubber,Or as per the customers’ requirements |

Surface Treatment |

Anodizing, Sandblasting, Painting, Powder coating, Electroplating, Silk Printing, Brushing, Polishing, Laser Engraving... |

Drawing Format |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl,etc |

Service Project |

To provide project design, production and technical service, mould development and fabrication, etc |

Testing Machine |

Digital Height Gauge, caliper, Three Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

Quality Assurance |

ISO9001:2015 Certified TUV |

Packing |

Foam, Carton, Wooden boxes, or as per the customer’s requirements |

Deliver |

DHL, FEDEX, UPS, TNT, EMS, SF Or according to customers′ requirement |