Custom Metalworking Casting Service Grey Iron Sand Casting Iron Part Aluminum Enclosure Die Casting Product Category

- Overview

- Recommended Products

Selecting the optimal casting process is critical for the performance, cost, and lifecycle of your component. Our comprehensive Custom Metalworking Casting Service offers two foundational manufacturing solutions: Grey Iron Sand Casting for unparalleled durability and Aluminum Enclosure Die Casting for lightweight, high-volume production. Understanding the distinction ensures you get the right part for your application.

Grey Iron Sand Casting: The Standard for Strength and Damping

Material & Performance: We use high-grade grey iron (Grade G3000 and above), renowned for its excellent damping capacity, which absorbs vibrations and reduces noise. It provides outstanding compressive strength and superior wear resistance, making it ideal for components under high static loads and friction. Its natural graphite microstructure also offers good machinability.

Production Process: Utilizing the versatile sand casting process, we create molds from resin-bonded sand. This method is cost-effective for low to medium production volumes and allows for the casting of very large, heavy parts with considerable design flexibility.

Primary Applications: Perfect for automotive brake discs and drums, heavy machinery bases, engine blocks, pump housings, and industrial equipment where vibration dampening and structural integrity are paramount.

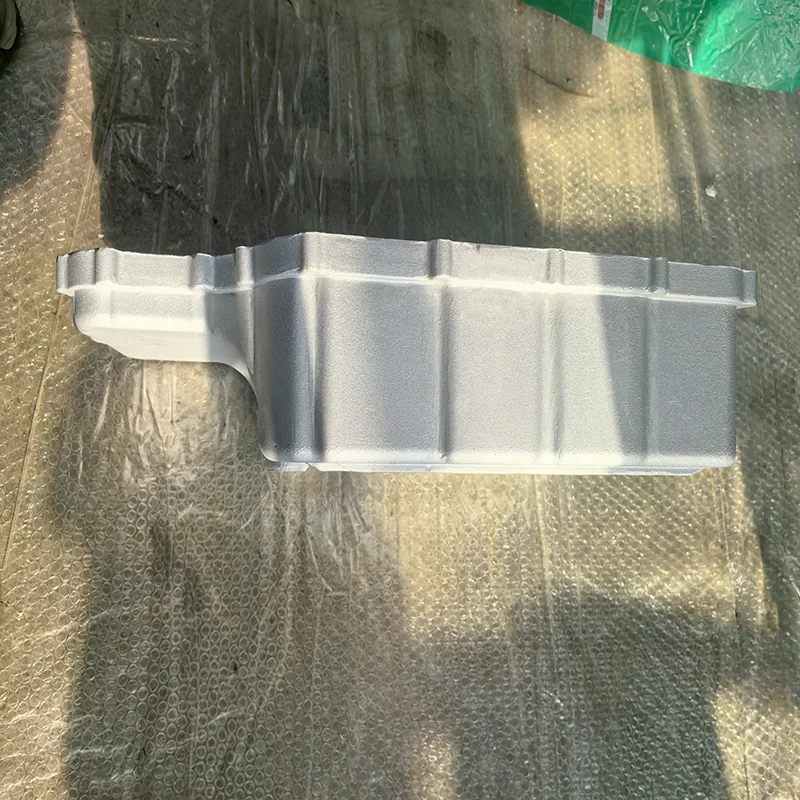

Aluminum Enclosure Die Casting: Precision for Lightweight Enclosures

Material & Performance: Our aluminum die casting employs alloys like A380 and ADC12, celebrated for their high strength-to-weight ratio and good corrosion resistance. These alloys allow for thin walls and complex geometries while maintaining excellent thermal and electrical conductivity.

Production Process: The high-pressure die casting process involves injecting molten aluminum into a precision steel mold at high speed. This results in high-volume production of parts with exceptional dimensional accuracy, smooth surface finish, and fine details.

Primary Applications: Ideal for electronic enclosures, heat sinks, automotive intake manifolds, consumer electronics housings, and telecommunications components where lightweight, shielding, and complex shapes are required.

Partner with our custom metalworking casting service for expert guidance on material and process selection, ensuring your Grey Iron Sand Casting or Aluminum Die Casting product is optimized for quality, performance, and value.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |