- Overview

- Recommended Products

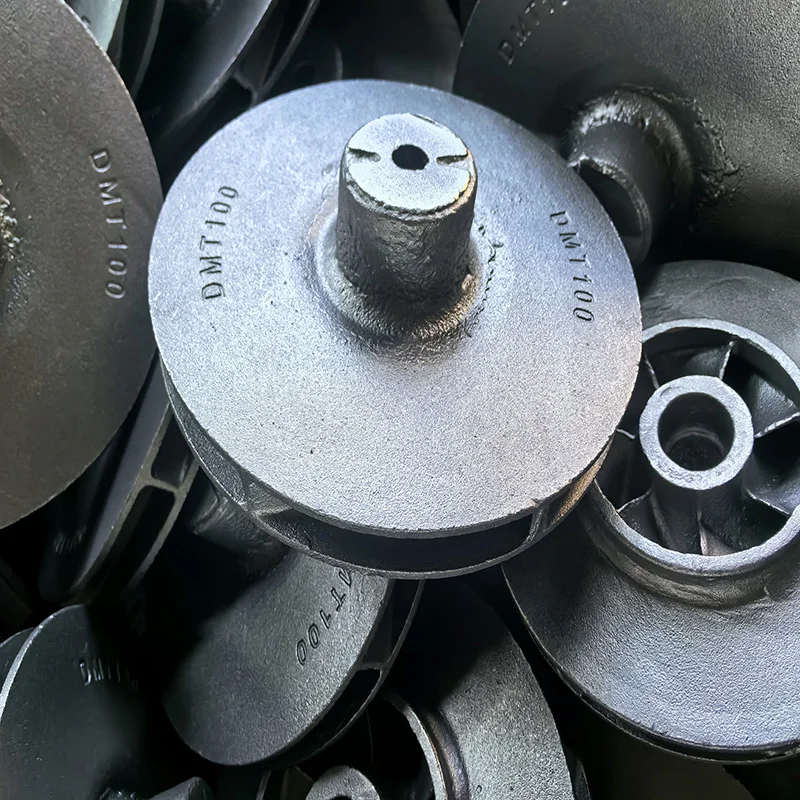

In agricultural machinery maintenance and repair operations, engine valves represent critical components that directly impact tractor performance, fuel efficiency, and operational reliability. Our custom casting services specialize in producing diesel engine valves for tractor applications, delivering precision components that withstand extreme temperature fluctuations, mechanical stress, and continuous operation demands. These specialized parts ensure optimal combustion chamber performance while maintaining dimensional stability under the rigorous conditions encountered in agricultural operations.

Material Excellence and Performance Characteristics

We utilize heat-resistant martensitic stainless steels (X45CrSi9-3, X53CrMnNiN21-9) and nickel-based superalloys specifically engineered for diesel engine valve applications. Our standard X45CrSi9-3 steel valves provide tensile strength of 950-1150 MPa at room temperature, maintaining mechanical integrity at operating temperatures up to 650°C. The material's chromium-silicon composition ensures exceptional oxidation resistance and wear characteristics against valve seat interfaces. Specialized coatings including chromium plating (15-40 μm) and aluminum diffusion coatings enhance surface hardness to 800-1000 HV while improving corrosion resistance in aggressive combustion environments. The materials demonstrate excellent thermal fatigue resistance, withstanding continuous thermal cycling between 200°C and 750°C throughout the valve's service life.

Precision Manufacturing Process

Our manufacturing integrates investment casting technology with precision machining to produce valves with optimal metallurgical structure and dimensional accuracy. The investment casting process begins with wax pattern injection using precision-designed molds that create the complex valve geometry with dimensional stability within ±0.005 inches. Ceramic shell building with multiple zircon-based layers ensures mold integrity during the vacuum-assisted pouring process. Following casting, each valve undergoes precision CNC machining on specialized lathes and grinding equipment, maintaining stem diameter tolerances within ±0.0015 inches and seat angle accuracy within ±0.5°. Heat treatment processes including solution annealing and tempering optimize the material's microstructure, while final surface treatments including polishing and coating application ensure optimal performance characteristics.

Tractor Diesel Engine Applications

Our custom cast engine valves serve critical functions in agricultural tractor diesel engines ranging from 50 to 500 horsepower. The components are engineered for both intake and exhaust applications in direct injection and common rail diesel systems, with designs optimized for specific combustion chamber configurations. Our manufacturing capabilities accommodate various valve sizes from 30mm to 60mm head diameter, with stem diameters of 6mm to 12mm to match original equipment specifications. The valves maintain reliable performance under continuous operation in demanding agricultural conditions including dust-laden environments, variable load operations, and extended service intervals characteristic of modern tractor usage.

Partner with our manufacturing expertise for custom cast tractor diesel engine valves that combine material superiority with precision engineering. Our comprehensive approach from alloy selection to finished components ensures valves that enhance engine performance, reduce maintenance frequency, and provide reliable service throughout extended operational lifetimes, supported by complete material certification and performance validation.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |