- Overview

- Recommended Products

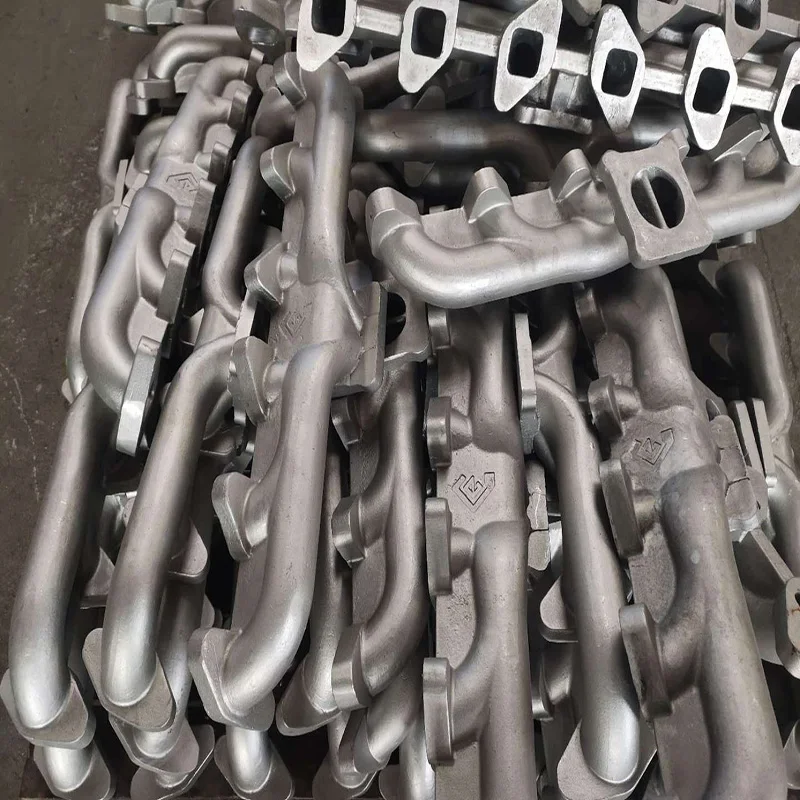

As a specialized manufacturer in precision components, we provide comprehensive CNC milling services for stainless steel rapid prototype machining parts combined with high-quality casting services. Our integrated manufacturing approach enables us to deliver precision components that bridge the gap between prototype development and production, ensuring seamless transition from concept to final product while maintaining the highest quality standards.

Material Excellence and Performance Characteristics

We work with premium stainless steel grades specifically selected for prototyping and production applications:

300 Series Stainless Steel

Our 304 and 316 stainless steel alloys offer excellent corrosion resistance and good mechanical properties. 304 stainless steel provides tensile strength of 515-620 MPa, while 316 stainless steel, enhanced with 2-3% molybdenum, delivers superior resistance to chlorides and industrial chemicals, making it ideal for marine and chemical processing applications.

400 Series Stainless Steel

We utilize 410 and 420 martensitic stainless steels for applications requiring higher strength and wear resistance. These alloys can be heat treated to achieve tensile strength up to 1650 MPa, providing exceptional durability for components subject to heavy wear and high stress conditions.

Precipitation-Hardening Grades

For critical applications demanding high strength and corrosion resistance, we offer 17-4PH stainless steel, which can be heat treated to achieve tensile strength of 1310 MPa while maintaining good dimensional stability and corrosion resistance.

Advanced Manufacturing Process

Our production methodology integrates state-of-the-art machining with precision casting:

CNC Milling Technology

We operate multi-axis CNC milling centers (3-axis, 4-axis, and 5-axis) capable of producing complex geometries with tight tolerances (±0.025mm). Our advanced milling capabilities include:

High-speed machining for efficient material removal

Precision contouring for complex surfaces

Micro-milling for intricate details

Simultaneous multi-axis machining for complex parts

Rapid Prototyping Process

Our rapid prototyping services ensure quick turnaround times without compromising quality:

CAD/CAM programming for fast design implementation

Rapid toolpath generation and optimization

Real-time machining monitoring

Quick-change fixture systems reducing setup times

Quality Assurance and Precision Validation

We maintain rigorous quality control throughout our manufacturing process:

First article inspection and comprehensive reporting

In-process dimensional verification

Surface finish analysis using profilometers

Material certification to ASTM standards

CMM validation for complex geometries

Applications and Industry Solutions

Our services support diverse industry requirements:

Aerospace: Prototype components and precision flight parts

Medical: Surgical instrument prototypes and medical device components

Automotive: Engine component prototypes and transmission parts

Industrial: Machinery components and equipment prototypes

Electronics: Enclosure prototypes and heat dissipation components

By combining advanced CNC milling technology with high-quality casting services, we deliver precision components that meet the most demanding requirements for both prototype development and production applications. Our engineering team works closely with clients to optimize designs for manufacturability, ensuring efficient production, reliable performance, and cost-effective solutions from initial concept through final production.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |