- Overview

- Recommended Products

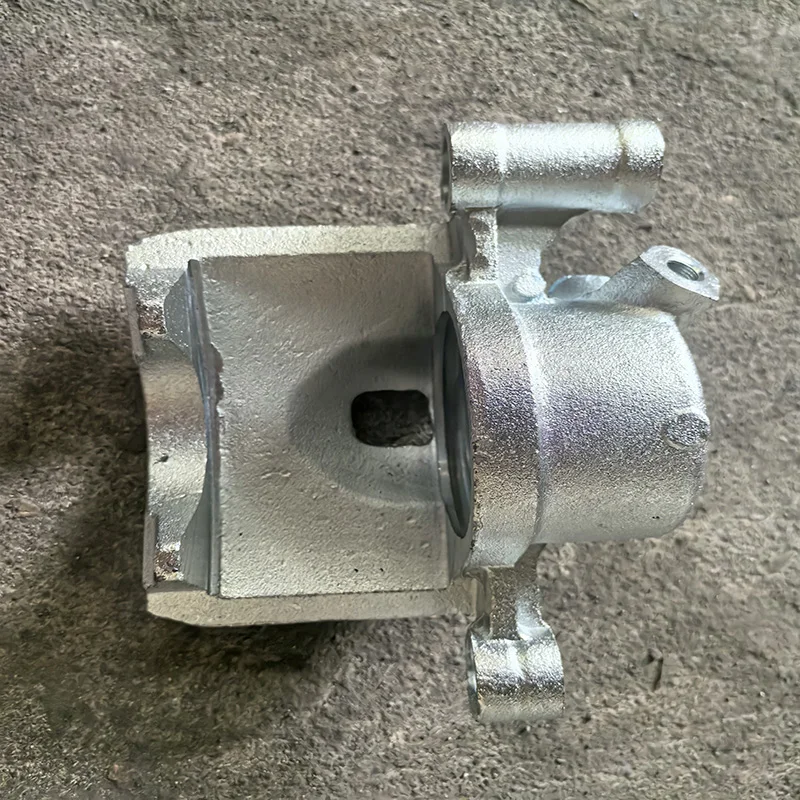

In the realm of mechanical power transmission and energy storage, the flywheel remains an indispensable component for ensuring smooth operational continuity. Our Cast Iron Flywheel, manufactured through premium casting services, represents the perfect synthesis of traditional robustness and modern precision engineering. This product delivers exceptional performance in energy management and rotational stability for a wide spectrum of industrial machinery and automotive systems.

Premium Material: High-Grade Cast Iron

The core of our flywheel's reliability lies in its material composition. We utilize high-grade gray cast iron, specifically Grade G3000 or higher, renowned for its excellent castability and, most importantly, its superior damping capacity. This inherent property allows the material to effectively absorb and dissipate vibrational energy, reducing harmonic oscillations within the drive system. The graphite flakes in the microstructure provide natural lubrication, reducing wear, while the material's high density is ideal for building the necessary moment of inertia in a compact design.

Performance and Engineering Excellence

Engineered for durability and efficiency, our cast iron flywheels deliver critical performance characteristics:

High Moment of Inertia: Optimized mass distribution ensures efficient energy storage, smoothing out pulsations from piston engines and providing consistent rotational force.

Exceptional Damping Capacity: Effectively suppresses torsional vibrations, protecting the engine or drive train from damaging oscillations and reducing noise.

Thermal Stability: Maintains structural integrity and dimensional accuracy under cyclic thermal loads.

Precision-Balanced: Dynamically balanced to high standards (e.g., G6.3 or better) to minimize centrifugal forces and ensure smooth operation at rated speeds, which is crucial for reducing bearing loads and overall system vibration.

Advanced Production and Casting Process

Our flywheels are produced using state-of-the-art green sand casting and no-bake sand casting processes, chosen for their ability to produce dense, defect-free castings with excellent surface finish. The process is meticulously controlled:

Pattern Making: Precision patterns are created to form the complex geometry of the flywheel, including spokes, rim, and hub.

Molding and Pouring: Molds are created from high-quality sand, and molten iron is poured at controlled temperatures to ensure optimal fluidity and solidification.

Heat Treatment: Castings undergo stress-relief annealing to eliminate internal stresses from the cooling process, thereby enhancing dimensional stability and preventing warping during machining.

CNC Machining: Critical surfaces, including the face, friction surface, and bore, are precision-machined on CNC lathes and milling centers. This guarantees exact tolerances for runout, parallelism, and concentricity, ensuring perfect alignment with the crankshaft and clutch assembly.

Primary Applications

Our premium cast iron flywheels are essential components in numerous applications:

Automotive and Diesel Engines: Standard in manual transmission vehicles, from passenger cars to heavy-duty trucks.

Industrial Machinery: Used in punch presses, shears, crushers, and stamping presses to store energy for high-peak power demands.

Power Generators: Serve as energy reservoirs in generator sets to maintain consistent RPM under fluctuating loads.

Agricultural Equipment: Integral to tractors and combines for maintaining consistent power delivery.

Marine Propulsion Systems: Provide rotational stability in marine engine applications.

Invest in a flywheel that guarantees operational smoothness and longevity. Our premium casting services deliver a product that is the cornerstone of efficient kinetic energy management in any mechanical system.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |