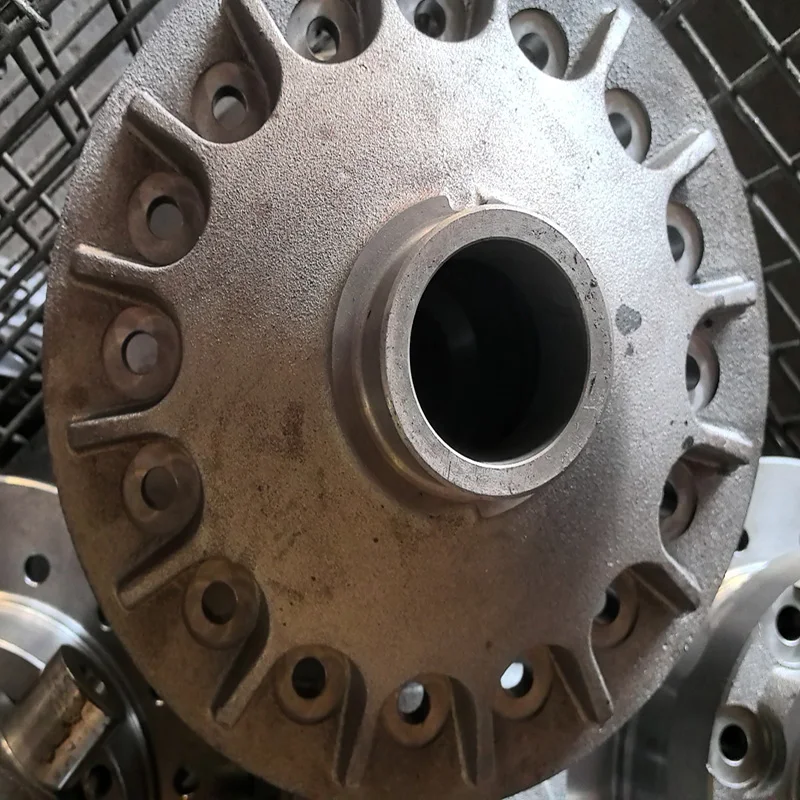

YA6 Customized Automotive Hub for Pickups CNC Machining Casting Services Quality Assured Auto Parts

- Overview

- Recommended Products

As a specialized manufacturer in automotive components, we provide customized YA6 series hubs specifically engineered for pickup applications. Our integrated CNC machining and casting services deliver precision hubs that ensure superior performance, reliability, and longevity for light truck and pickup platforms operating under demanding conditions.

Material Excellence and Performance Characteristics

We utilize high-grade ductile iron (Grade 65-45-12) and forged steel alloys specifically selected for automotive hub applications. The ductile iron provides excellent tensile strength of 448 MPa and yield strength of 310 MPa, while maintaining good impact resistance with 12% elongation. Our material composition ensures:

Superior fatigue resistance for extended service life

Excellent wear resistance against bearing contact surfaces

Optimal weight-to-strength ratio for vehicle unsprung mass

Enhanced corrosion resistance for all-weather operation

Consistent performance across temperature variations from -40°C to 120°C

Advanced Manufacturing Process

Our production methodology combines precision casting with CNC machining:

Precision Casting Technology

We employ resin sand casting processes that enable:

Consistent wall thickness maintaining structural integrity

Complex internal geometries for weight optimization

Superior surface finish reducing machining requirements

Minimal porosity ensuring maximum strength

CNC Machining Integration

Our comprehensive machining capabilities include:

Precision turning of bearing mounting surfaces (IT6 tolerance)

Multi-axis milling for complex flange geometries

Deep hole drilling for stud and bolt applications

Thread machining for secure component attachment

Surface grinding for critical sealing interfaces

Quality Assurance and Performance Validation

Each hub undergoes rigorous testing and validation:

Magnetic particle inspection for surface defect detection

Ultrasonic testing for internal integrity verification

Coordinate measuring machine dimensional analysis

Dynamic balancing testing for rotational components

Hardness testing confirming material specifications

Salt spray testing for corrosion resistance validation

Application-Specific Engineering

Our YA6 series hubs are specifically designed for:

Light Truck Applications: Heavy-duty construction for payload capacity

Off-Road Use: Enhanced strength for rough terrain operation

Commercial Fleets: Extended service life for high-mileage applications

Performance Pickups: Optimized design for modified vehicles

Replacement Market: Direct OEM specification compliance

By combining advanced casting technology with precision CNC machining, we deliver automotive hubs that exceed industry standards for performance, reliability, and durability. Our engineering team works directly with customers to develop customized solutions that meet specific application requirements, ensuring perfect fitment, optimal performance, and quality-assured operation for pickup truck applications worldwide.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |