- Overview

- Recommended Products

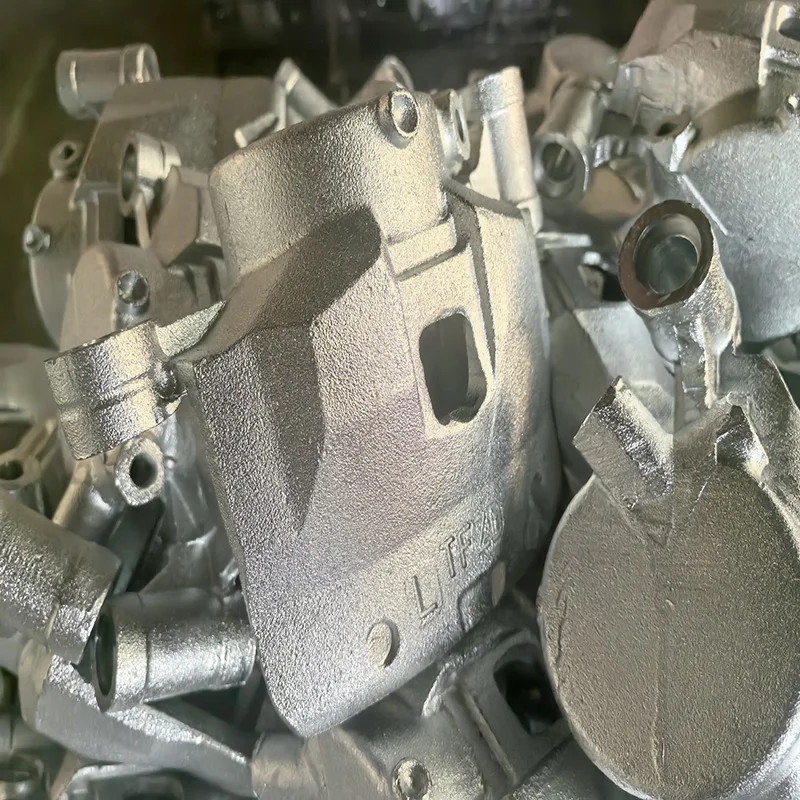

In the high-stakes environment of forced induction, the turbocharger bearing housing stands as a critical component, directly influencing performance, reliability, and longevity. Our Premium Casting Services specialize in manufacturing high-integrity Cast Iron Bearing Housings that meet the extreme demands of modern turbocharger applications. We deliver a product engineered for superior thermal management, structural stability, and dimensional precision, ensuring optimal performance in both automotive and industrial turbocharging systems.

Advanced Material for Extreme Conditions

The bearing housing operates under severe thermal cycling and mechanical stress. We utilize high-grade Ductile Iron (Spheroidal Graphite Iron), specifically chosen for its exceptional combination of properties:

High-Temperature Strength: Maintains structural integrity and load-bearing capacity at sustained elevated temperatures, resisting creep and deformation.

Excellent Thermal Conductivity: Facilitates efficient heat dissipation from the bearing cartridge and shaft, crucial for preventing oil coking and bearing failure.

Outstanding Wear Resistance: Withstands the constant micro-movement and friction from the bearing assembly, ensuring long service life.

Good Machinability: Allows for the precision machining of critical oil and coolant galleries, as well as bearing bores, to tight tolerances.

Precision-Controlled Production Process

Our manufacturing process is tailored to create housings with flawless internal integrity and complex internal passages.

Sand Casting Technique: We employ high-precision sand casting with chemically-bonded molds. This method is ideal for forming the complex geometries of coolant jackets and oil passages in a single, robust piece.

Process Control: Rigorous control over molding, pouring temperatures, and cooling rates ensures a dense, homogeneous microstructure free from shrinkage, porosity, or inclusions that could lead to catastrophic failure under pressure.

Integrated Machining: As a one-stop service, we provide complete CNC machining. This includes precision boring of the bearing cartridge seat, finishing of sealing surfaces, and drilling of all necessary ports, guaranteeing perfect fit and function.

Rigorous Quality Assurance

Every bearing housing undergoes stringent inspection, including dimensional checks and non-destructive testing (NDT) such as liquid penetrant testing, to verify surface integrity. This ensures the component is free from defects that could compromise its function in a high-RPM environment.

Application-Specific Engineering

Our cast iron bearing housings are designed for:

Automotive & Performance Turbochargers

Heavy-Duty Diesel & Marine Turbochargers

Industrial Turbochargers and Turbo-Compressors

By leveraging our Premium Casting Services, you secure a critical turbocharger component built for durability and performance. Partner with us for a reliable supply of bearing housings that enhance turbocharger efficiency and service life.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |