- Overview

- Recommended Products

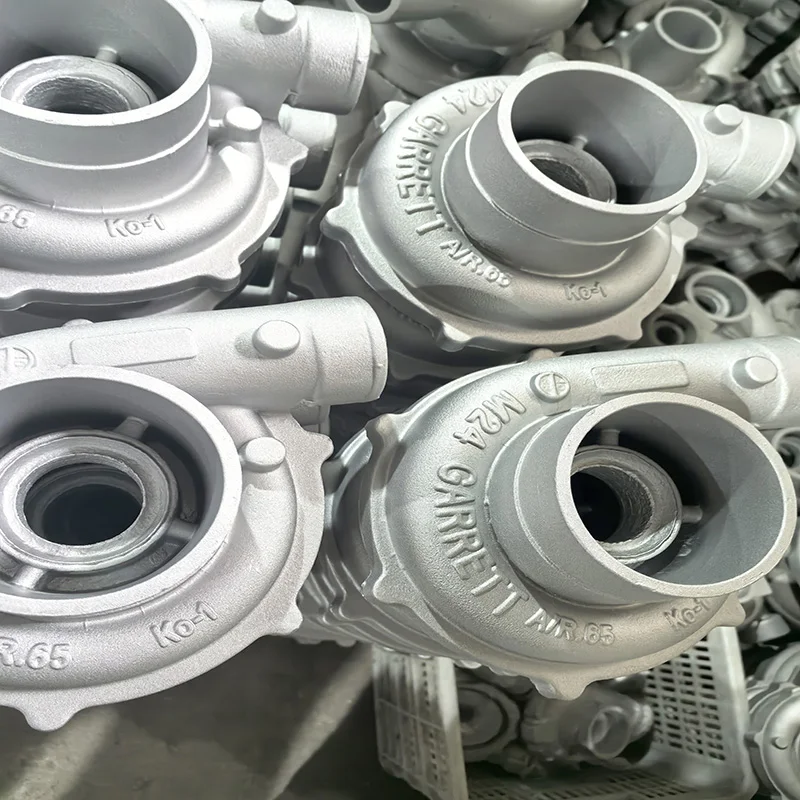

In the competitive landscape of precision manufacturing, achieving the perfect synergy of high-volume production and exceptional accuracy is the ultimate goal. Our Top Quality CNC Machining Die Casting Series represents this pinnacle, offering a seamless integration of high-pressure die casting with precision CNC machining. This end-to-end service is engineered for industries where dimensional perfection, superior surface finishes, and robust mechanical properties are non-negotiable, providing a reliable solution from prototype to mass production.

Premium Materials for Demanding Applications

Our die casting series utilizes high-performance materials, primarily focusing on aluminum and zinc alloys, chosen for their specific advantageous properties:

Aluminum Alloys (e.g., A380, ADC12): Celebrated for their excellent strength-to-weight ratio, good corrosion resistance, and high thermal and electrical conductivity. These alloys are ideal for creating lightweight yet strong components with complex geometries.

Zinc Alloys (e.g., Zamak 3, Zamak 5): Known for their high impact strength, exceptional dimensional stability, and superior castability for thin walls. They offer excellent surface quality for plating and finishing.

Advanced Two-Stage Manufacturing Process

The "Top Quality" designation is earned through our rigorous, two-phase manufacturing protocol:

-

High-Pressure Die Casting: The process begins with injecting molten metal under intense pressure into precision-engineered steel molds (dies). This method produces near-net-shape parts with:

Rapid Production Cycles: Enabling high-volume output.

Complex, Thin-Wall Geometries: Creating intricate shapes impossible with other methods.

Excellent Surface Finish: Minimizing post-processing requirements.

-

Precision CNC Machining: The die-cast parts then undergo meticulous CNC machining. This critical secondary operation is where true precision is achieved, including:

Holding Critical Tolerances: Machining features like bore diameters and thread pitches to exact specifications.

Creating Precise Features: Drilling and tapping holes, milling flat surfaces, and achieving perfect perpendicularity.

Deburring and Finishing: Ensuring the final part is clean, smooth, and ready for assembly or coating.

Unmatched Performance Advantages

The combination of these processes delivers components with distinct advantages:

Dimensional Accuracy and Repeatability: CNC machining ensures every part in the series is identical and within spec.

Enhanced Structural Integrity: The dense, fine-grained structure from die casting provides a strong base.

Cost-Effectiveness at Scale: Die casting is efficient for high volumes, while targeted CNC machining minimizes waste.

Design Flexibility: Achieve complex forms via casting and precise functional features via machining.

Ideal for High-Stakes Industries

Our Top Quality Series is trusted in sectors such as:

Automotive: Engine brackets, transmission housings.

Aerospace: Lightweight structural components.

Electronics: Heat sinks, device housings.

Consumer Goods: High-durability appliance and tool parts.

Elevate your product quality and manufacturing efficiency. Contact us today to explore how our Top Quality CNC Machining Die Casting Series can provide the precision and reliability your projects demand.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |