- Overview

- Recommended Products

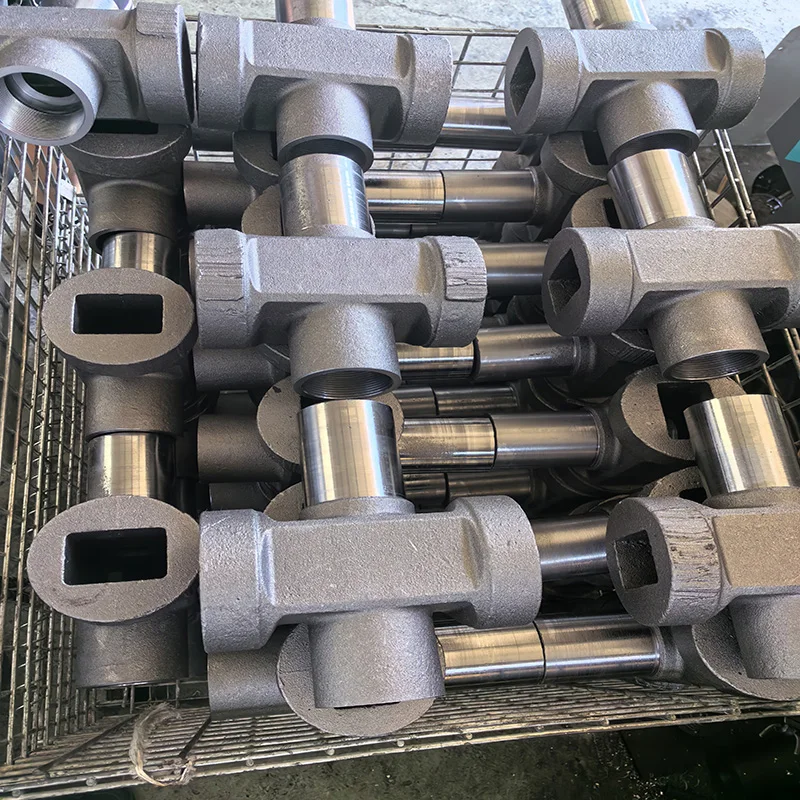

In the world of industrial machinery, safeguarding the heart of the system—the motor—is paramount. A Sand Casting Cast Iron Motor Casing provides the essential, robust enclosure that ensures operational integrity, safety, and longevity. This foundational manufacturing process delivers housings renowned for their strength and reliability, protecting vital motor components from harsh operating environments.

The material choice of high-quality cast iron is central to the casing's performance. Typically, grades like grey cast iron are utilized for their exceptional damping capacity, which absorbs vibrational energy and reduces noise—a critical factor for smooth motor operation. Cast iron also offers outstanding compressive strength and excellent machinability, allowing for precise finishing of bearing seats and mounting surfaces to ensure perfect alignment and fit.

The production of these durable casings relies on the versatile and cost-effective sand casting process. This method involves creating a mold from compacted sand, which is formed around a pattern of the desired casing. For complex internal geometries, sand cores are inserted into the mold. Once the molten cast iron is poured and solidifies, the sand mold is broken away, yielding a single, solid casting. This process is highly adaptable, making it ideal for producing large, heavy-duty motor casings in both low and high volumes, from small industrial motors to massive turbine enclosures.

The application of sand-cast iron motor casings is universal across heavy industries. They are the standard enclosure for motors in mining equipment, pumping stations, industrial fans, conveyor systems, and agricultural machinery. Their rugged construction protects internal windings and rotors from contaminants like dust, moisture, and physical impact, ensuring uninterrupted operation in demanding conditions.

Opting for a sand-cast cast iron motor casing means investing in proven protection and performance. It is the trusted solution for engineers seeking a durable, cost-effective, and reliable housing that extends the service life of critical motor assets.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |