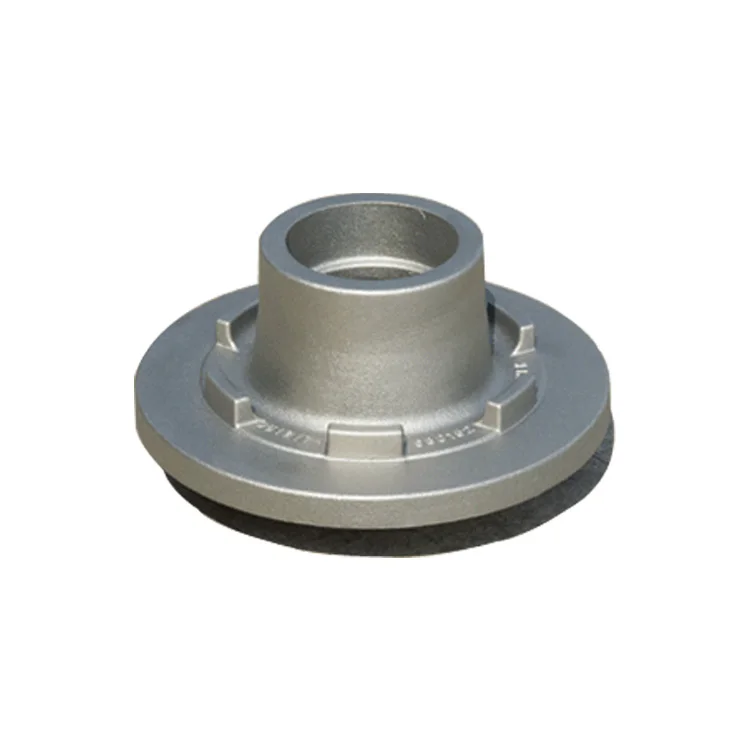

OEM Factory High Precision Steel Metal Iron Valve Handwheel Sand Casting for Industrial Applications

- Overview

- Recommended Products

In industrial fluid control systems, valve handwheels represent critical interface components where ergonomic design meets functional reliability. Our OEM factory specializes in high-precision sand casting of steel, metal, and iron valve handwheels that combine superior mechanical properties with operational safety. Through advanced sand casting technology and rigorous quality control, we deliver handwheel components that ensure smooth valve operation, long service life, and compatibility with diverse industrial environments.

Premium Material Selection

We offer comprehensive material options to meet specific application requirements:

Carbon Steel Castings: ASTM A216 WCB grade providing excellent strength and impact resistance

Stainless Steel Alloys: CF8/CF8M (304/316 equivalent) for superior corrosion resistance

Ductile Iron Components: ASTM A536 65-45-12 delivering optimal strength-to-weight ratio

Gray Iron Castings: ASTM A48 Class 35B for cost-effective solutions with good machinability

All materials undergo strict chemical composition control and mechanical property verification to ensure consistent performance in demanding industrial applications.

Advanced Sand Casting Manufacturing Process

Our precision-focused production system ensures quality at every stage:

-

Pattern Design & Manufacturing

CNC-machined wood, epoxy, and metal patterns with precise draft angles

3D printed prototypes for design validation and customer approval

Custom core box development for complex spoke geometries

-

Molding Technology

Resin sand molding for superior surface finish and dimensional accuracy

Automated green sand molding lines for high-volume production

No-bake sand systems for large and complex handwheel configurations

-

Casting Excellence

Controlled pouring with degassing and inoculation treatment

Real-time thermal monitoring during solidification

Optimized gating and risering systems for sound casting structure

-

Post-Casting Processing

Stress relieving heat treatment for dimensional stability

CNC machining of hub surfaces, keyways, and mounting features

Shot blasting and surface treatment for corrosion protection

Balancing verification for smooth rotational operation

Performance Advantages

Ergonomic Design: Optimized spoke configuration and rim diameter for comfortable operation

High Strength & Durability: Robust construction withstands repeated operational stresses

Excellent Corrosion Resistance: Suitable for various industrial environments and media

Superior Machinability: Precision-machined interfaces ensure perfect fit with valve stems

Reliable Performance: Proven durability in continuous industrial service

Quality Assurance Protocol

ISO 9001:2015 certified quality management system

Dimensional verification using coordinate measuring machines

Liquid penetrant testing for surface defect detection

Mechanical property testing for each production batch

Complete material traceability and certification documentation

Technical Applications

Industrial valve manufacturing and repair

Oil and gas pipeline systems

Chemical and petrochemical processing plants

Water treatment and distribution systems

Power generation and marine applications

Our engineering team provides comprehensive OEM support from design optimization through production, ensuring perfect compatibility with your valve systems and operational requirements. We maintain flexible production capabilities from prototype development to mass production, with full compliance with international quality standards. Contact our technical specialists today to discuss your valve handwheel requirements and benefit from our high-precision sand casting expertise for your industrial applications.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |