High Quality Stainless Steel CNC Turned Parts with Precision Machining Polishing and Cylindrical Center Hole Casting Services

- Overview

- Recommended Products

In industries where precision, durability, and reliability are non-negotiable, high-quality stainless steel CNC turned parts stand as a critical manufacturing solution. These components form the backbone of advanced machinery across various sectors, delivering unmatched performance through a combination of superior material properties and state-of-the-art manufacturing processes.

Superior Material for Demanding Applications

The foundation of these parts is high-grade stainless steel, such as 303, 304, 316, and 316L. This material is chosen for its excellent mechanical properties, including high tensile strength, remarkable corrosion resistance, and good machinability. Whether facing harsh chemicals, extreme temperatures, or constant wear, stainless steel ensures long-term integrity and functionality, making it ideal for medical, aerospace, automotive, and food processing applications.

Advanced Manufacturing and Finishing Processes

The creation of these parts begins with Precision CNC Machining. Computer Numerical Control (CNC) lathes and turning centers expertly shape raw stainless steel bar stock into complex geometries with tight tolerances, often within microns. This process guarantees consistency and accuracy for every single part in a production run.

For components requiring specific features like a Cylindrical Center Hole, precision machining ensures perfect concentricity and surface finish, which is crucial for assembly and rotational balance. Furthermore, secondary operations like Precision Machining Polishing are applied to enhance the surface. This can range from a standard deburring to a mirror-like finish, which not only improves aesthetics but also further boosts corrosion resistance by eliminating surface imperfections where contaminants could gather.

A Comprehensive Service for Your Projects

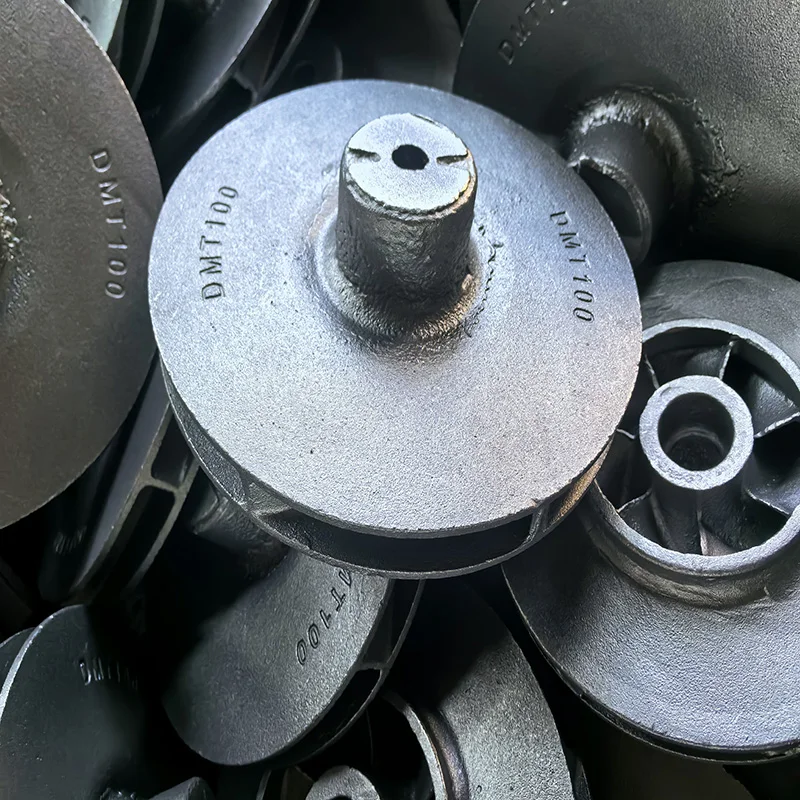

Choosing a supplier that offers integrated Casting Services alongside machining provides a complete manufacturing package. This allows for the production of near-net-shape raw castings that are then finished to exact specifications on CNC turning equipment, optimizing both cost and material usage.

From intricate surgical instrument shafts to robust hydraulic fittings, high-quality stainless steel CNC turned parts are engineered for excellence. By leveraging precision machining, expert polishing, and comprehensive cylindrical hole casting services, manufacturers can secure a reliable source for components that drive innovation and ensure operational success.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |