High Quality Custom Metal Foundry Steel Ductile Iron Sand Casting Precision Parts in Aluminum Alloy

- Overview

- Recommended Products

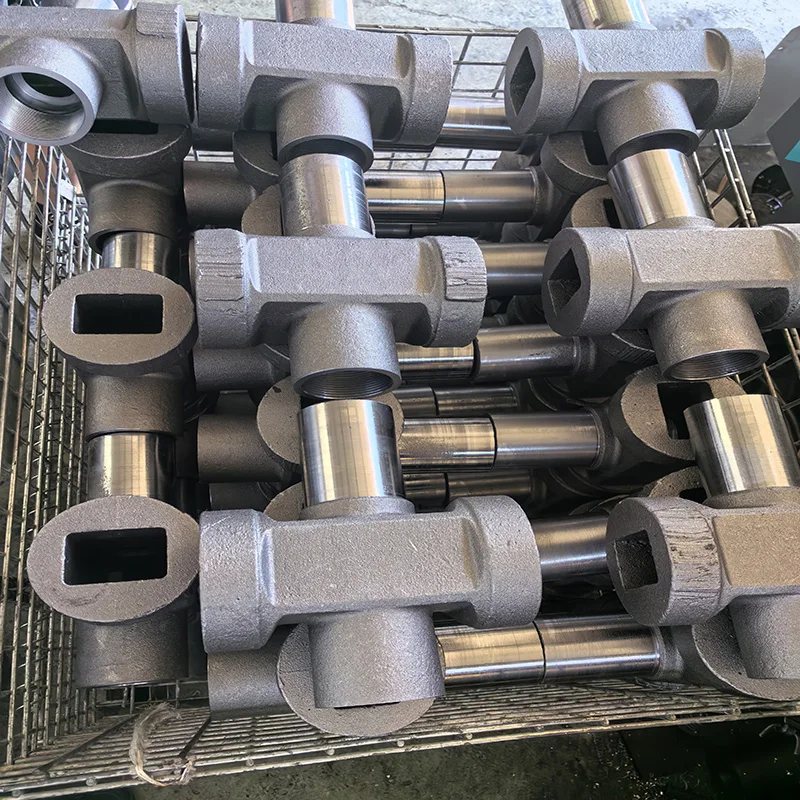

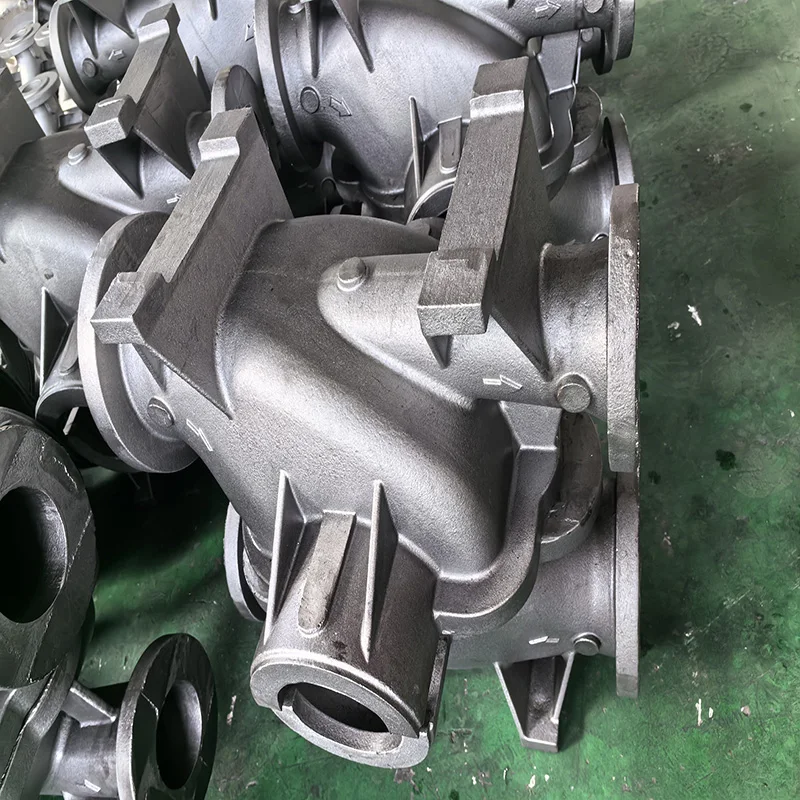

In today's demanding industrial landscape, component reliability directly impacts operational success. Our High Quality Custom Metal Foundry provides comprehensive casting solutions specializing in Steel, Ductile Iron Sand Casting, and Precision Parts in Aluminum Alloy. We deliver engineered components that meet rigorous performance standards across diverse applications, combining material expertise with advanced manufacturing capabilities to become your trusted casting partner.

Advanced Material Selection

Our foundry masters three primary material systems to meet specific application requirements. For Steel components, we offer carbon and low-alloy steels (1020, 1045, 4140, 8630) providing excellent strength and impact resistance. Our Ductile Iron castings (grades 65-45-12, 80-55-06, 100-70-03) deliver the optimal balance of strength, ductility, and wear resistance with superior machinability. For lightweight applications, our Aluminum Alloy precision parts (A356, 356, 319, 535) offer exceptional strength-to-weight ratios, corrosion resistance, and thermal conductivity, making them ideal for diverse industrial applications.

Precision Manufacturing Process

Our sand casting capabilities utilize advanced chemically-bonded molding systems, including phenolic urethane no-bake and furan sand systems, ensuring dimensional accuracy and superior surface finish. The process incorporates computer simulation to optimize solidification patterns and minimize potential defects. For aluminum components, we employ both green sand and permanent mold processes, selected based on production volume and geometric complexity. All castings undergo rigorous quality control, including dimensional verification, liquid penetrant testing, and radiographic examination when specified.

Enhanced Performance Characteristics

Components produced through our foundry services deliver:

Exceptional mechanical properties tailored to application requirements

Superior surface finish minimizing post-casting machining

Consistent dimensional accuracy across production runs

Excellent structural integrity under static and dynamic loading

Outstanding wear and corrosion resistance in demanding environments

Reliable performance across temperature extremes

Comprehensive Application Spectrum

Our casting services support critical components across multiple sectors:

Heavy Equipment: Ductile iron gear cases, steel mounting brackets, aluminum hydraulic components

Transportation Industry: Aluminum alloy engine brackets, ductile iron suspension parts

Energy Sector: Steel valve bodies, ductile iron pump casings

Industrial Machinery: Aluminum alloy compressor parts, ductile iron press frames

Marine Applications: Corrosion-resistant aluminum fittings and bronze components

By leveraging our High Quality Custom Metal Foundry expertise in Steel, Ductile Iron Sand Casting, and Precision Aluminum Alloy Parts, you gain a manufacturing partner committed to delivering components that excel in performance, reliability, and value. Our technical capabilities ensure your castings meet the most demanding specifications while optimizing production efficiency and total cost of ownership.

OEM Service |

Investment Casting |

Die Casting |

Sand Casting |

Stamping/Forging |

||||

Weight |

5g-50kg |

0.5kg-1000kg |

0.5kg-1ton |

|||||

Capacity |

200ton/month |

500ton/month |

1000ton/month |

200ton/month |

||||

Machining tolerance |

±0.01-0.03mm |

±0.02mm |

||||||

Surface roughness |

6.4 Raum/254 Rauinches |

3.2 Raum/125 Rauinches |

12.5 Raum |

|||||

MOQ |

200 pcs |

1000 pcs |

200 pcs |

1000 pcs |

||||

Material for cast |

304 316 stainless steel carbon steel |

A380 A356 aluminum aluminum alloy zinc alloy |

Iron grey iron ductile iron aluminum |

Stainless aluminum brass carbon steel |

||||

Add-Value Service |

Add-Value Service |

|||||||

Coating |

Anodizing Zinc plating |

Paining |

Powder coating |

Electroplating |

||||

Machining |

Turning |

Milling |

Drilling |

Boring |

||||

Cutting&Forming |

Key cutting |

EDM |

Welding |

|||||

Heat Treatment |

Hardening |

Normalizing |

Quenching&Tempering |

Annealing |

||||