- Overview

- Recommended Products

Material Excellence and Performance Characteristics

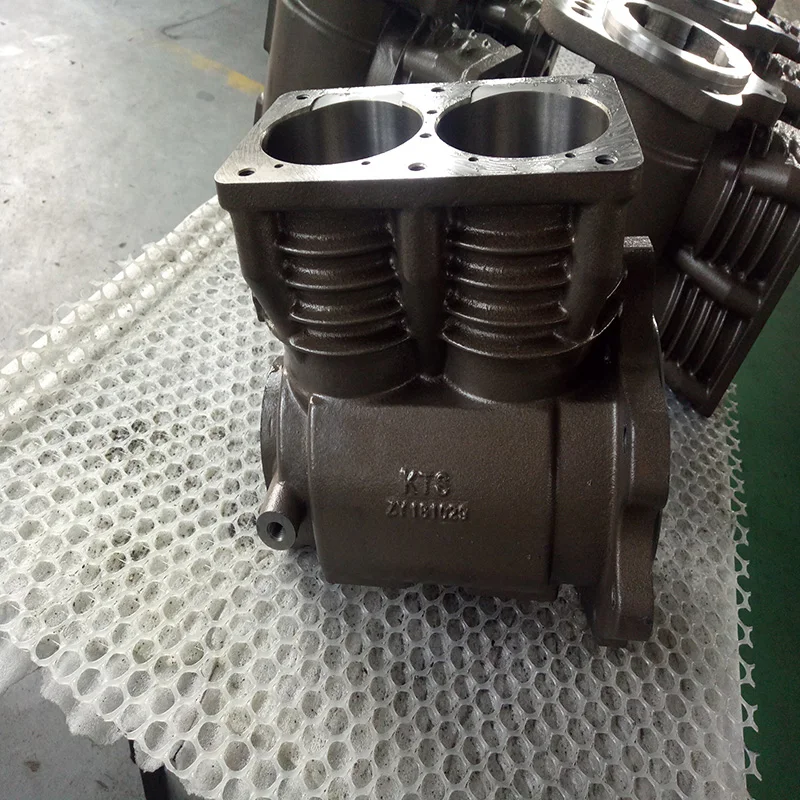

Our foundry utilizes high-grade ductile iron (Grades 50007, 60003, 70002) characterized by its unique spherical graphite microstructure within an iron matrix. This advanced material delivers superior mechanical properties including tensile strength ranging from 500-700 MPa, impressive elongation capabilities (7-2%), and exceptional impact resistance. The nodular graphite formation provides ductile iron with remarkable fatigue strength and vibration damping capacity, outperforming standard gray iron in applications requiring both strength and durability. These material characteristics ensure excellent wear resistance, pressure integrity, and reliable performance under thermal cycling conditions.

Advanced Green Sand Casting Process

We employ state-of-the-art green sand casting technology utilizing automated molding systems with high-pressure compaction to create precise, repeatable molds. Our process begins with carefully controlled sand mixtures combining silica sand, bentonite clay, water, and additives to achieve optimal mold strength and permeability. The controlled pouring process ensures proper filling of complex mold cavities, while our rigorous quality control monitors every stage from pattern making to final shakeout. Post-casting, components undergo heat treatment (annealing, normalizing, or quenching/tempering) to achieve desired microstructures and mechanical properties, followed by precision machining of critical surfaces to meet exact dimensional requirements.

Comprehensive Industrial Applications

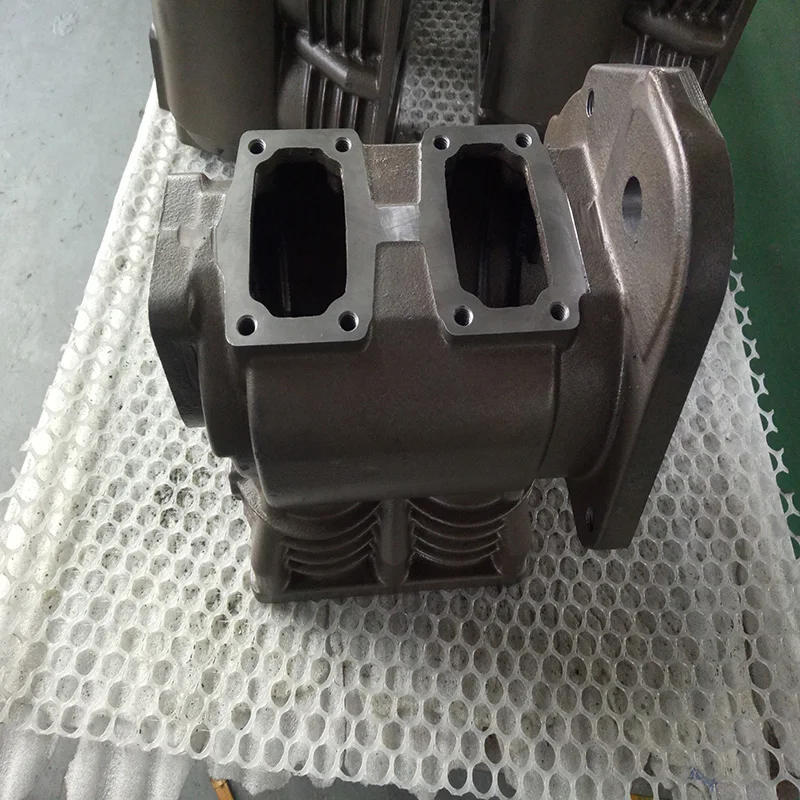

Our green sand-cast ductile iron products serve diverse applications across multiple industries. In automotive and transportation, we produce steering knuckles, brake calipers, and suspension components that demand high strength-to-weight ratios. The agricultural sector utilizes our castings for tractor transmission cases, implement gears, and harvester components requiring exceptional wear resistance. Additionally, we manufacture valve bodies, pump housings, and compressor parts for fluid handling systems, along with heavy machinery components including gear blanks, sheaves, and hydraulic press frames where durability and reliability are paramount.

Partner with our green sand casting foundry for ductile iron products that deliver uncompromising quality and performance. Our commitment to manufacturing excellence, combined with the inherent advantages of ductile iron, provides engineering solutions that enhance product longevity, reduce maintenance requirements, and offer superior value across countless industrial applications.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |