Customized Industrial Aluminum Sand and Gravity Casting Featuring Design Drawing Premium Casting Services Product

- Overview

- Recommended Products

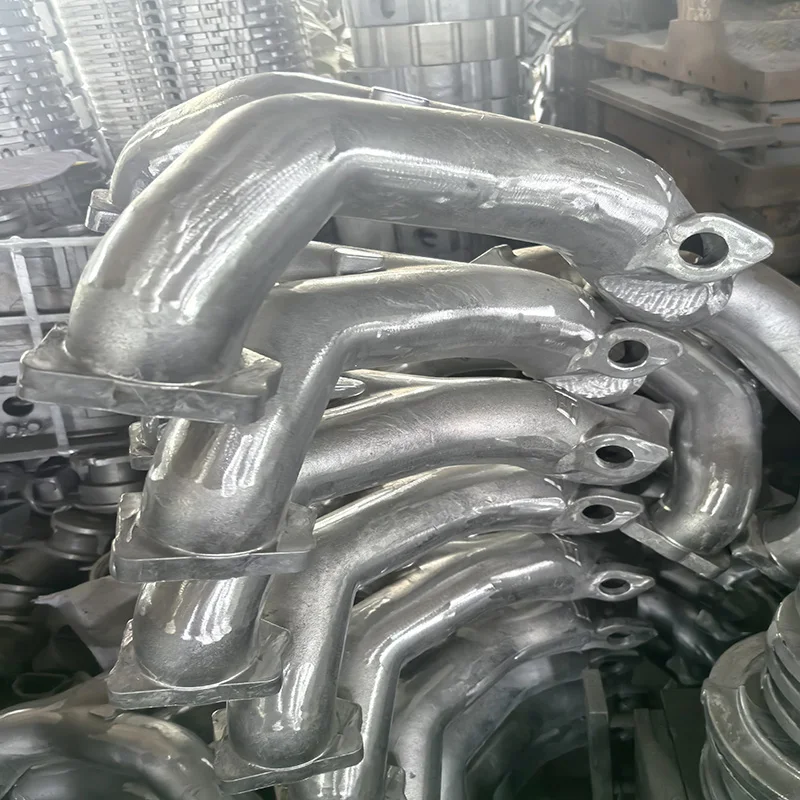

In industrial manufacturing where precision, durability, and customization are critical, Customized Industrial Aluminum Sand and Gravity Casting Services provide the foundational solution for producing high-performance components. By integrating advanced design drawing analysis with proven casting techniques, these services deliver aluminum parts that meet stringent specifications across diverse industries, from automotive to heavy machinery.

Advanced Aluminum Alloys for Superior Performance

The process utilizes high-strength aluminum alloys, primarily from the Al-Si series (such as A356), known for their excellent castability and balanced mechanical properties -1. These alloys are selected for their:

High Strength-to-Weight Ratio: Ideal for applications requiring lightweight yet durable components -10.

Excellent Corrosion Resistance: Suitable for harsh operating environments -10.

Good Thermal Conductivity: Beneficial for heat dissipation in engine and electronic components -10.

Enhanced Mechanical Properties: Achieved through precise control of alloy composition and heat treatment, with T6 heat treatment (e.g., 545°C solidification and 160°C aging) significantly boosting tensile strength and durability -1.

Precision Manufacturing Process: From Design to Finished Product

The casting process begins with a thorough analysis of Design Drawing specifications, ensuring every detail is optimized for manufacturability and performance. This is followed by:

Sand Casting: Ideal for complex geometries, large-sized parts, and low-to-medium volume production -2-6. It uses resin-bonded sand molds to create precise cavities. The process allows for flexibility in design and is cost-effective for prototype development or smaller batches -6. Technologies like 3D printing of sand cores further enable the production of complex internal structures, such as integrated water channels in engine components -6.

Gravity Casting (Metal Mold Casting): This method uses reusable metal molds, typically made from materials like H-13 steel, known for its high-temperature strength and durability, leading to mold lives often exceeding 100,000 cycles -3-7. It offers superior surface finish, dense internal structure -3, and high dimensional consistency, making it suitable for larger production runs -7. The process involves pouring molten aluminum into the mold under gravity, resulting in components with improved mechanical properties due to faster cooling rates -7.

Both processes are often complemented by heat treatment to enhance strength and machining to achieve final dimensional accuracy.

Key Advantages for Industrial Applications

Design Flexibility: Capable of producing components with complex shapes, thin walls, and intricate internal features, validated through prototype simulation -5.

Cost-Effectiveness: Sand casting minimizes initial tooling costs, while gravity casting offers efficiency for higher volumes -4-6.

Quality Assurance: Incorporates process control measures, such as regulating mold temperature in gravity casting -3-7 and employing low-pressure filling in sand casting to minimize gas porosity -6, to ensure casting integrity.

Wide-Ranging Industrial Applications

These casting services are essential in sectors including:

Automotive: Engine blocks, cylinder heads, and structural supports -7.

Aerospace: Large, structurally complex components that benefit from the design freedom of sand casting and the integrity of gravity cast parts -5.

Machinery and Equipment: Pump housings, valve bodies, and heavy-duty machine components -10.

Energy and Electrical: Enclosures and heat sinks that leverage aluminum's good thermal properties -10.

By leveraging Customized Industrial Aluminum Sand and Gravity Casting Services, engineers and manufacturers gain a reliable partnership that transforms design concepts into high-integrity components. This approach ensures not only the feasibility of production but also optimizes performance, durability, and cost-efficiency for critical applications.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |