Customized Aluminum Gravity-Casting Relief Valve Cover Lower Main Valve Cover Casting Services Product

- Overview

- Recommended Products

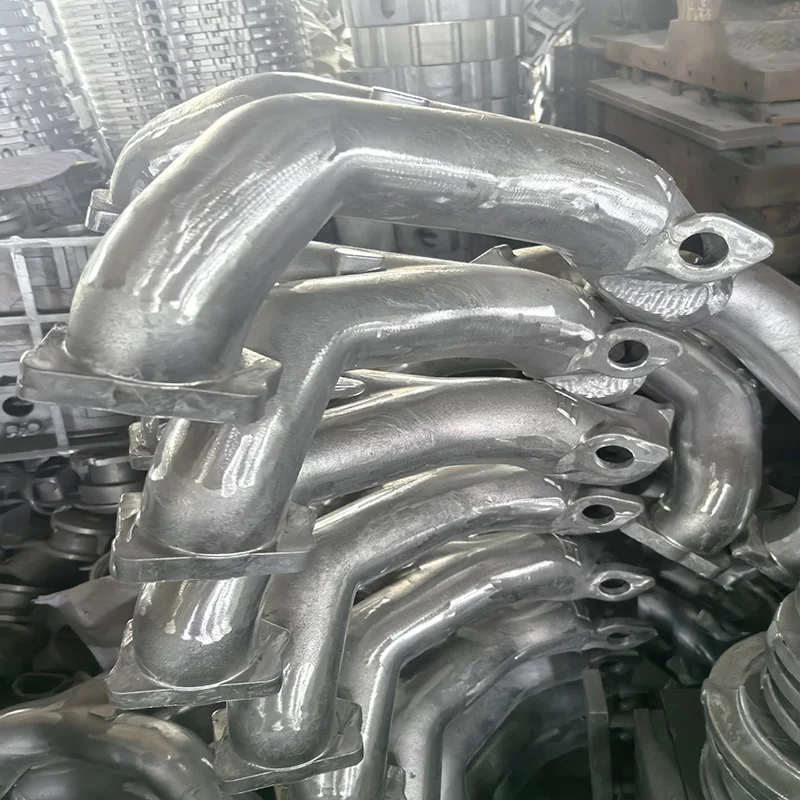

In precision fluid control systems where reliability under pressure is non-negotiable, the integrity of valve components is paramount. Our Customized Aluminum Gravity-Casting Services specialize in producing critical Relief Valve Covers and Lower Main Valve Covers that meet the most demanding performance specifications. Engineered for superior metallurgical integrity and dimensional precision, these castings provide the definitive solution for applications requiring leak-proof operation and long-term durability in challenging environments.

Advanced Material Excellence

We utilize high-strength aluminum alloys, primarily A356-T6 and 319 aluminum, selected for their exceptional combination of lightweight properties and mechanical performance. The A356-T6 alloy undergoes solution heat treatment and artificial aging to achieve a typical tensile strength of 45 ksi (310 MPa) and yield strength of 32 ksi (220 MPa), providing outstanding structural capability. These alloys offer excellent corrosion resistance, particularly in aqueous and chemical environments, while maintaining good thermal conductivity to dissipate operational heat effectively. The material's enhanced fatigue resistance ensures reliable performance under cyclic pressure conditions.

Precision Gravity Casting Manufacturing Process

Our gravity casting process represents the optimal manufacturing method for valve components requiring superior metallurgical properties. The controlled mold filling technique eliminates turbulence and gas entrapment that can compromise component integrity. The process begins with precision-machined permanent molds coated with ceramic-based releases to achieve exceptional surface finish. Molten aluminum is poured at carefully controlled temperatures, with tilt-pour systems ensuring laminar flow into the mold cavity. This method produces components with denser microstructure, reduced porosity, and enhanced mechanical properties compared to alternative casting methods, while maintaining tight dimensional tolerances of ±0.005 inches per inch.

Optimized Performance Characteristics

Valve covers produced through our customized gravity casting process deliver:

Superior pressure tightness for leak-free operation

Enhanced structural integrity under high-pressure conditions

Excellent resistance to corrosion and erosion

Consistent mechanical properties throughout the component

Superior surface finish minimizing post-casting machining requirements

Outstanding thermal stability maintaining dimensional accuracy

Critical Application Versatility

Our customized aluminum gravity-cast valve covers serve essential functions across multiple industries:

Hydraulic Systems: Relief valve covers for pressure control units and accumulator assemblies

Process Industries: Lower main valve covers for chemical processing, refinery, and pipeline valves

Marine and Offshore: Critical valve components for seawater systems and ballast control

Power Generation: Safety and relief valve applications in steam and turbine systems

Industrial Machinery: Custom valve solutions for compressed air and hydraulic circuits

By choosing our Customized Aluminum Gravity-Casting Services for your Relief Valve Cover and Lower Main Valve Cover requirements, you secure components engineered for maximum reliability in critical pressure-containing applications. Our technical expertise ensures each casting delivers optimal performance, extended service life, and uncompromising quality for your most demanding fluid handling systems.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |