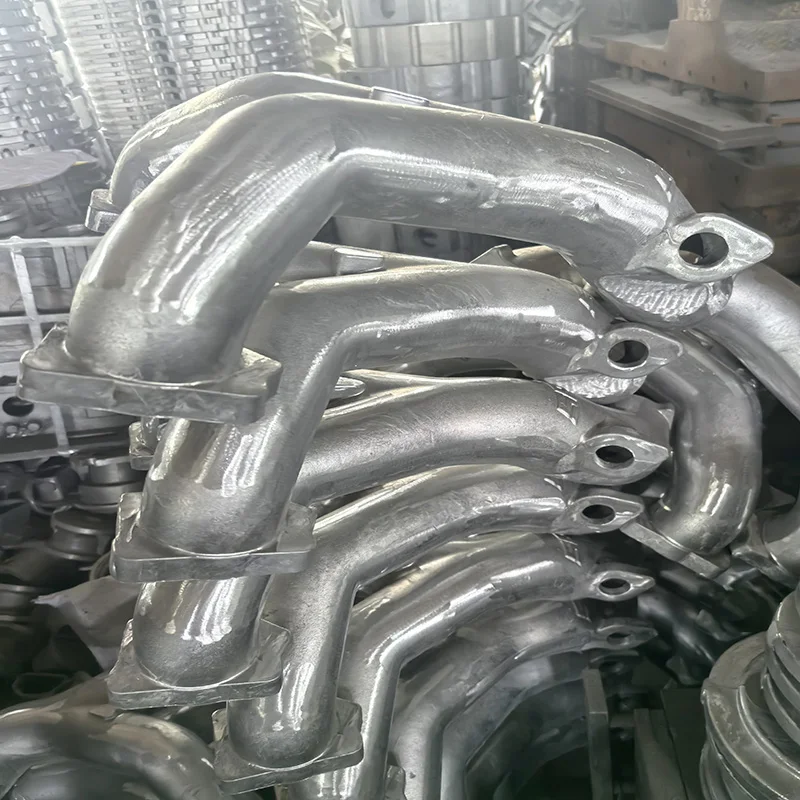

Customized Aluminum Casting Services 16-Cylinder Diesel Engine Intake Manifold & Exhaust Pipe

- Overview

- Recommended Products

In the realm of high-performance heavy machinery and power generation, the demands on a 16-cylinder diesel engine are extreme. Critical to its efficiency and power output are the intake and exhaust systems. Our Customized Aluminum Casting Services specialize in producing high-integrity Intake Manifolds and Exhaust Pipes that meet the rigorous thermal and structural challenges of these powerful engines. We deliver precision-engineered components designed to optimize airflow, manage intense heat, and ensure long-term reliability.

High-Performance Aluminum Alloys for Extreme Conditions

We utilize advanced, heat-treatable aluminum alloys such as A356-T6 and 319, which are specifically selected for this demanding application. These materials offer an exceptional combination of:

High-Temperature Strength: Resists creep and deformation under the intense heat of exhaust gases, maintaining structural integrity.

Excellent Thermal Conductivity: Facilitates efficient heat dissipation from the exhaust pipe and prevents heat soak in the intake manifold, helping to maintain cooler, denser intake air.

Outstanding Strength-to-Weight Ratio: Provides the necessary durability while significantly reducing weight compared to cast iron, contributing to overall engine efficiency.

Superior Corrosion Resistance: Withstands exposure to corrosive exhaust byproducts and environmental elements.

Precision-Controlled Manufacturing Process

Our manufacturing approach is tailored to create complex, leak-free components with intricate internal passages.

Gravity & Low-Pressure Permanent Mold Casting: These processes allow for the production of manifolds and pipes with superior metallurgical integrity, dense microstructure, and excellent dimensional accuracy. The controlled filling minimizes turbulence and porosity, which is critical for preventing gas leaks and ensuring part strength.

Integrated Core Technology: We use sophisticated sand cores to form the complex internal runners and passages of the intake manifold, ensuring smooth airflow for optimal volumetric efficiency.

Complete CNC Machining: As a one-stop service, we provide full machining of all sealing surfaces, flanges, and mounting points. This guarantees perfect fitment to the cylinder heads and turbochargers, which is essential for engine performance and emissions control.

Rigorous Quality Assurance

Every intake manifold and exhaust pipe undergoes stringent testing, including dimensional inspection and pressure leak testing, to ensure it meets the high-pressure and high-temperature requirements of a 16-cylinder diesel engine.

Proven Application in Demanding Sectors

Our custom-cast aluminum components are engineered for:

Marine Propulsion Engines

Stationary Power Generation Units

Locomotive and Heavy-Haul Mining Equipment

Partner with us for your critical engine components. Our customized aluminum casting services deliver the performance, durability, and precision required to keep the most powerful engines operating at their peak.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |