Customizable Hob Hydraulic Cylinder Lever Machine Tool Equipment Hydraulic Cylinders Casting Services Product

- Overview

- Recommended Products

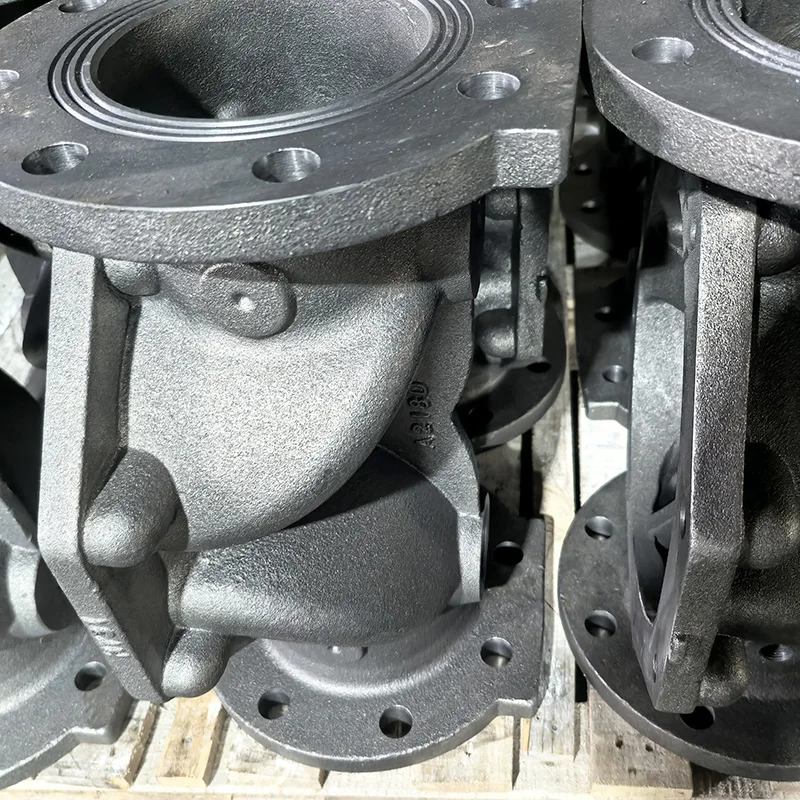

In industrial machinery and equipment manufacturing, hydraulic cylinders serve as critical power transmission components that determine system reliability and operational efficiency. Our Customizable Hob Hydraulic Cylinder Lever Machine Tool Equipment Hydraulic Cylinders Casting Services deliver precision-engineered solutions for demanding industrial applications. These specialized casting services provide robust, high-performance hydraulic cylinders that withstand extreme pressures while maintaining precise dimensional stability in machine tool and equipment applications.

Premium Material Engineering

We utilize high-strength cast iron and alloy steels specifically engineered for hydraulic applications:

Ductile Iron GGG40/50/60: Providing tensile strength of 400-600 MPa with excellent pressure containment capabilities

Gray Iron GG25/30: Offering superior vibration damping with compression strength exceeding 600 MPa

Low-Alloy Steel Grades: Delivering enhanced yield strength and fatigue resistance for high-pressure applications

Special Alloy Variants: Chromium and molybdenum additions for improved wear and corrosion resistance

All materials undergo comprehensive testing including spectrochemical analysis, mechanical property validation, and microstructure examination to ensure compliance with international hydraulic component standards.

Advanced Casting and Manufacturing Process

Our integrated production system combines sophisticated foundry technology with precision machining:

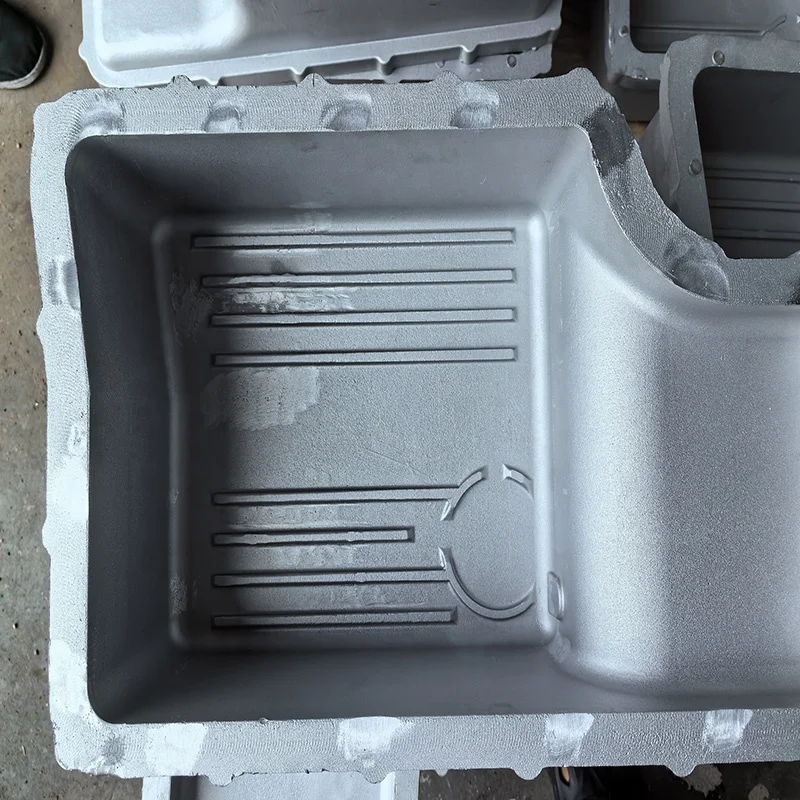

Casting Technology

Resin sand molding with 3D printed cores for complex internal passages

Controlled pouring temperatures (1420-1480°C) ensuring proper fluidity

Computerized solidification simulation preventing shrinkage defects

Real-time thermal monitoring during casting process

Precision Machining

CNC boring of cylinder barrels maintaining straightness within 0.01mm/m

Precision grinding of piston rod surfaces achieving Ra 0.2-0.4 μm

Thread machining to ISO 1179 and ISO 9974 standards

Coordinate measuring machine verification of all critical dimensions

Performance Characteristics

Our hydraulic cylinder castings deliver:

Pressure ratings from 160 to 400 bar depending on application

Surface hardness of 200-250 HB for optimal wear resistance

Dimensional stability under cyclic loading conditions

Excellent machinability for precise component integration

Corrosion resistance suitable for various hydraulic fluids

Quality Assurance Protocol

Each hydraulic cylinder component undergoes rigorous validation:

Ultrasonic testing for internal integrity assessment

Magnetic particle inspection for surface defect detection

Pressure testing to 1.5 times maximum operating pressure

Dimensional verification using laser scanning technology

Material certification with full traceability documentation

Technical Applications

Our customizable hydraulic cylinders serve critical functions in:

Hob and gear cutting machine applications

Industrial press and forming equipment

Material handling system actuators

Construction machinery hydraulic systems

Specialized machine tool equipment

Our engineering team provides comprehensive technical support including:

Custom design for specific pressure and load requirements

Integration with existing hydraulic systems

Port configuration and mounting customization

Seal compatibility optimization

By combining advanced casting technology with precision manufacturing capabilities, we deliver hydraulic cylinders that ensure reliable performance, extended service life, and reduced maintenance costs. Our customizable approach guarantees perfect compatibility with specific equipment requirements while maintaining the highest standards of quality and performance in demanding industrial environments.

Name |

Push pull double acting tie rod welded piston hydraulic cylinder |

Working Pressure |

5800PSI max. |

Bore Dia. |

2''2.5''3''3.5''4''5'' |

Heat Treatment |

Quenching |

Sealing Parts |

From USA Herculesus |

Quality Guarantee |

1 year |

Inspection |

100% inspection before shipping |

Sample |

For free |

Certificate |

ISO9001:2008 |

Packing |

Wooden Box |

Product Keywords |

one way hydraulic cylinder |