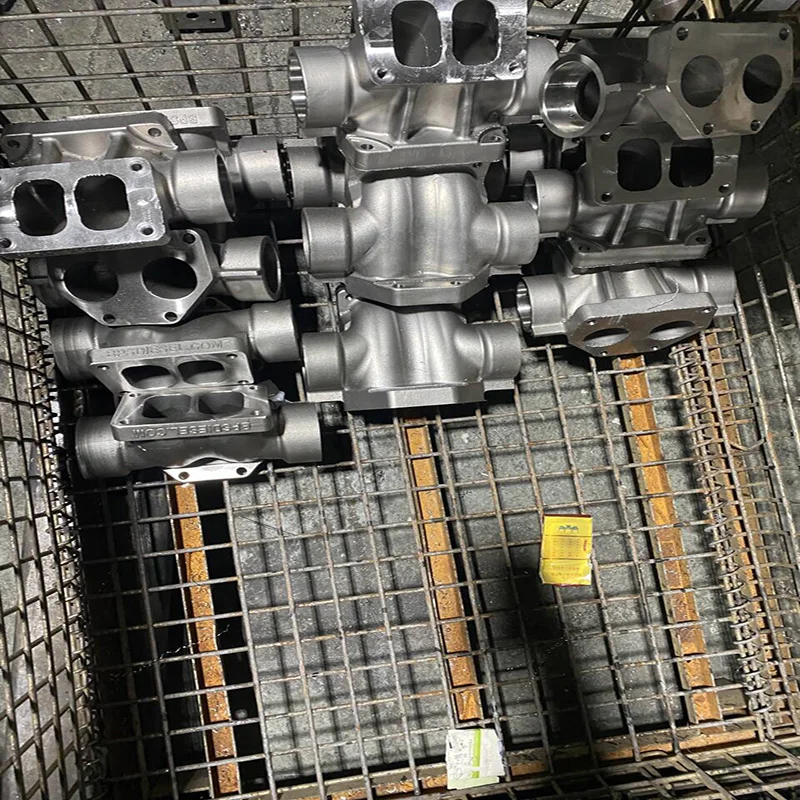

In today's demanding industrial landscape, components must withstand extreme conditions while maintaining precise dimensional stability. Our China foundry specializes in precision investment casting services for complex stainless steel parts, delivering exceptional quality and performance for critical applications across aerospace, medical, automotive, and industrial sectors. We combine advanced manufacturing technology with rigorous quality control to produce components that meet the most stringent international standards.

Premium Stainless Steel Materials

We offer comprehensive stainless steel alloy selection to match specific application requirements:

304/L Stainless Steel: Delivers excellent corrosion resistance and formability for general applications

316/L Stainless Steel: Provides enhanced corrosion resistance with molybdenum addition, ideal for chemical and marine environments

17-4PH Stainless Steel: Precipitation-hardening grade offering high strength (up to 1100 MPa) and good corrosion resistance

420 Stainless Steel: Martensitic grade providing high hardness and wear resistance after heat treatment

All materials undergo spectroscopic analysis and certification to ensure compliance with ASTM, ISO, and other relevant standards, guaranteeing consistent mechanical properties and chemical composition.

Advanced Investment Casting Process

Our manufacturing leverages state-of-the-art investment casting technology:

Pattern and Mold Creation

Rapid prototyping using 3D printed patterns for complex geometries

Multi-layer ceramic shell building with controlled humidity and temperature

Automated slurry systems ensuring consistent shell thickness

Casting and Finishing

Vacuum and air melting in controlled atmosphere furnaces

Precision pouring with temperature monitoring ±10°C

Automated shell removal and cut-off operations

Heat treatment including solution annealing and aging per material requirements

Precision Engineering Capabilities

We maintain exceptional dimensional control and surface quality:

Tolerance capabilities: ±0.005 inches per inch (standard), ±0.002 inches (precision)

Surface finish: 125-250 Ra as-cast, 32-63 Ra with secondary processing

Minimum wall thickness: 0.5 mm for most alloys

Weight range: from 0.01 kg to 50 kg per piece

Comprehensive Secondary Operations

Our integrated services include:

CNC machining of critical features and mounting surfaces

Heat treatment for optimized mechanical properties

Non-destructive testing (X-ray, dye penetrant, ultrasonic)

Surface treatments (passivation, electroplating, painting)

Assembly and welding of multi-component systems

Quality Assurance and Applications

Each component undergoes rigorous validation:

First article inspection with comprehensive reporting

Statistical process control throughout manufacturing

Material traceability with full documentation

Performance testing under simulated service conditions

Our precision cast stainless steel parts serve demanding applications including:

Aerospace: turbine blades, engine components, structural parts

Medical: surgical instruments, implantable devices, equipment housings

Automotive: turbocharger components, fuel system parts, sensors

Industrial: valves, pumps, fluid handling components, food processing equipment

By leveraging China's manufacturing advantages while maintaining international quality standards, we deliver complex stainless steel parts that combine superior performance with cost-effectiveness. Our engineering team works closely with clients from design optimization through production, ensuring optimal manufacturability and performance for each unique application.

About Us