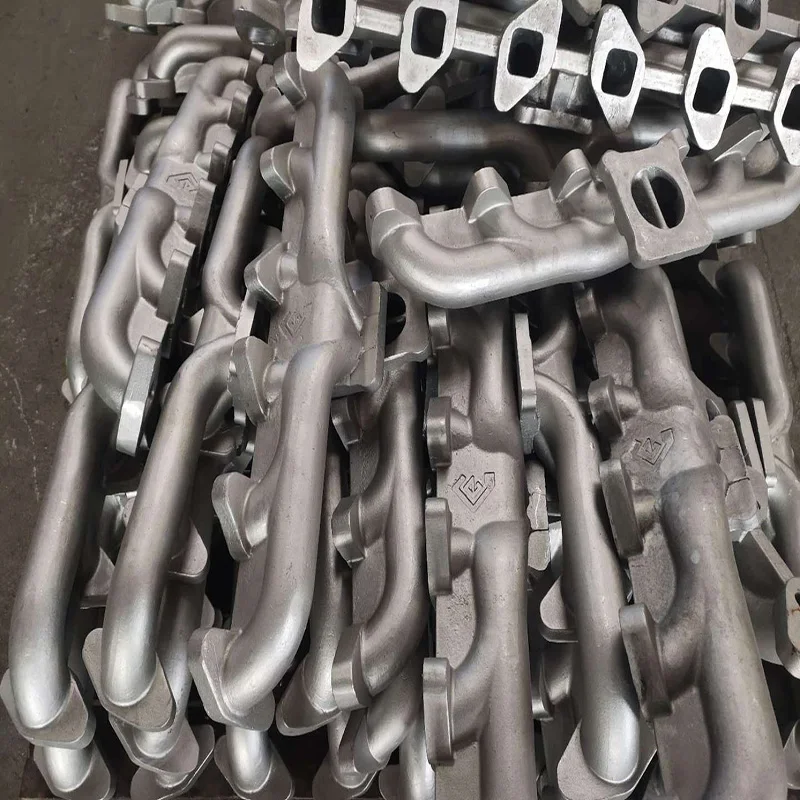

Carbon Steel and Stainless Steel 304 316 Lost Wax Investment Casting with Custom Thickness & OEM/ODM Accepted

- Overview

- Recommended Products

In precision manufacturing where complex geometries and superior surface finish are paramount, lost wax investment casting stands as a premier solution. Our specialized services utilize high-performance materials including carbon steel and stainless steel 304/316 to produce components with custom thickness and comprehensive OEM/ODM support. This advanced manufacturing approach delivers exceptional dimensional accuracy and mechanical properties for demanding applications across aerospace, medical, automotive, and industrial sectors.

Premium Material Selection

We offer engineered material solutions to meet diverse operational requirements:

Carbon Steel Grades

Mild to Medium Carbon Steel: Delivering excellent machinability and balanced strength for general industrial components

High-Carbon Steel: Providing superior wear resistance and hardness for cutting tools and wear parts

Stainless Steel Series

304 Stainless Steel: Offering excellent corrosion resistance and formability for food processing and chemical equipment

316 Stainless Steel: Featuring enhanced corrosion resistance with molybdenum addition, ideal for marine and pharmaceutical applications

Advanced Lost Wax Investment Casting Process

Our precision manufacturing workflow ensures consistent quality:

-

Pattern Creation

Injection of wax patterns using precision molds

Assembly of complex pattern clusters for multiple components

-

Shell Building

Successive ceramic coating applications

Controlled drying and hardening processes

-

Dewaxing & Firing

Advanced steam autoclave dewaxing systems

High-temperature furnace firing for shell strengthening

-

Casting & Finishing

Controlled atmosphere melting and pouring

Precision shell removal and cut-off operations

Heat treatment and surface finishing per specifications

Customization & Quality Assurance

Custom Thickness: Capability to produce walls from 1.5mm to 100mm+

OEM/ODM Services: Complete engineering support from design to production

Quality Certifications: ISO 9001:2015 quality management system

Comprehensive Testing: X-ray, liquid penetrant, and dimensional inspection

Performance Advantages

Complex Geometry: Capable of producing intricate shapes impossible with other methods

Superior Surface Finish: Achieving Ra 3.2 μm or better as-cast

Excellent Dimensional Accuracy: Maintaining tolerances of ±0.005 mm/mm

Material Integrity: Homogeneous microstructure with minimal defects

Industry Applications

Aerospace: Turbine blades, engine components

Medical: Surgical instruments, implantable devices

Automotive: Turbocharger parts, transmission components

Industrial: Valve bodies, pump impellers, machinery parts

Partner with us for precision investment casting solutions that combine material expertise with advanced manufacturing capabilities. Contact our engineering team today to discuss your custom project requirements and discover how our OEM/ODM services can bring your designs to life with uncompromising quality.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |