- Overview

- Recommended Products

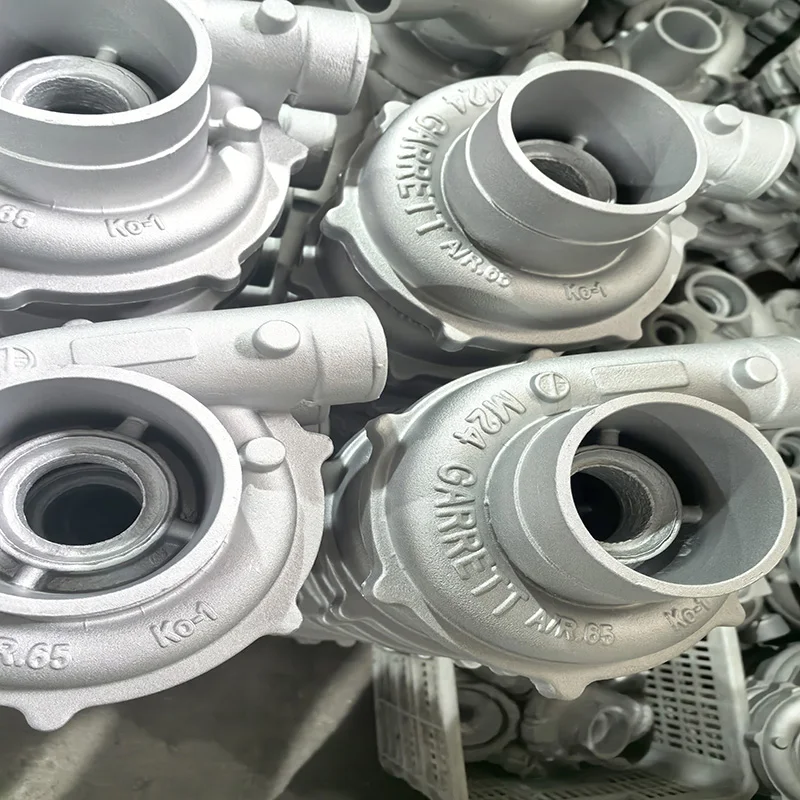

In the world of precision aluminum components, the choice of casting method and finishing technique directly impacts performance, aesthetics, and cost. Our specialized services in Aluminum Die Casting and Aluminum Gravity Casting, complemented by professional Bead Blasting Services, provide a comprehensive manufacturing solution for a wide spectrum of industrial applications. We engineer parts that meet stringent specifications for durability, dimensional accuracy, and surface quality.

Advanced Processes for Specific Performance Needs

Understanding the distinction between our two core processes is key to selecting the optimal solution for your project:

Aluminum Die Casting Parts: This high-pressure process forces molten aluminum into a steel mold at extreme velocity. It is ideal for high-volume production of complex, thin-walled components with exceptional dimensional consistency and fine detail. Die-cast parts offer high strength and a very good as-cast surface finish, making them suitable for components where intricate features and rapid production are critical.

Aluminum Gravity Casting: Utilizing permanent steel molds, this process relies on gravity to fill the cavity. It produces parts with a denser internal structure, superior metallurgical integrity, and reduced porosity compared to die casting. Gravity casting is the preferred method for components requiring enhanced pressure tightness, better mechanical properties, and superior weldability, often for aerospace, automotive, and military applications.

High-Strength Aluminum Alloys

We employ a range of premium alloys, including A380 for die casting for its excellent fluidity and A356 for gravity casting for its outstanding strength-to-weight ratio and heat treatability. These materials ensure components possess excellent corrosion resistance, good thermal conductivity, and structural integrity.

Bead Blasting: The Key to a Premium Finish

Our in-house Bead Blasting Services are a critical value-added step. This process involves propelling fine glass or ceramic beads at the component's surface to achieve a uniform, satin-smooth matte finish. Bead blasting effectively:

Removes minor surface imperfections and oxidation.

Creates a consistent, non-directional texture ideal for subsequent coatings like anodizing or painting.

Enhances the visual appeal, providing a clean, professional look.

Applications Across Industries

Our castings are vital in sectors such as:

Automotive: Transmission cases, engine brackets, and intake manifolds.

Telecommunications: Heat sinks and electronic enclosures.

Power Tools: Durable housings and gearboxes.

Medical Equipment: Robust and cleanable device housings.

By integrating casting and finishing, we ensure a seamless workflow and guaranteed quality. Partner with us for aluminum components that deliver on both technical performance and aesthetic appeal.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |