- Overview

- Recommended Products

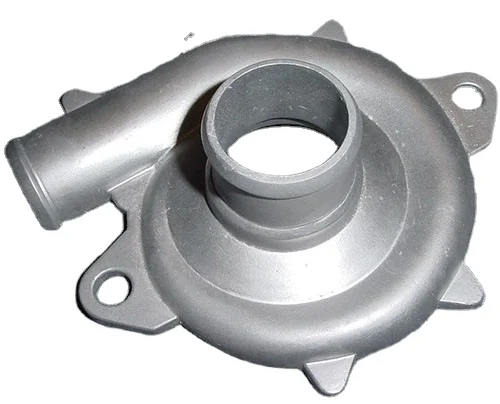

In the demanding realm of turbocharging and turbine technology, the compressor housing plays a pivotal role in engine efficiency and performance. Our specialized Aluminum Casting Services for Turbine Compressor Housing deliver the optimal combination of lightweight design, thermal management, and structural integrity required for high-velocity airflow applications, making them the preferred choice for automotive, aerospace, and power generation industries.

Advanced Aluminum Alloys for Superior Performance

We utilize high-strength aluminum alloys specifically engineered for high-temperature and high-stress environments:

A356-T6: Excellent castability with superior strength-to-weight ratio and proven pressure tightness

C355: Enhanced fatigue resistance and mechanical properties for high-rotation applications

A354: Superior yield strength and impact resistance for demanding operating conditions

These alloys maintain dimensional stability across temperature ranges from -50°C to 250°C while offering excellent corrosion resistance.

Precision-Engineered Manufacturing Process

Our integrated manufacturing approach ensures optimal housing performance:

-

Advanced Casting Techniques

Low-Pressure Die Casting: Ensures dense metallurgical structure with minimal porosity

Sand Casting: Suitable for complex volute geometries and prototype development

Investment Casting: Delivers superior surface finish and dimensional accuracy

-

CNC Machining & Finishing

5-axis machining for precise compressor wheel clearance and mounting surfaces

Bore machining with tolerances within ±0.01mm for optimal wheel alignment

Internal surface finishing to minimize airflow turbulence and maximize efficiency

Critical Performance Characteristics

Our aluminum compressor housings deliver:

Exceptional Heat Dissipation: Rapid thermal transfer prevents heat buildup

High Pressure Containment: Withstands boost pressures exceeding 4 bar

Reduced Inertia: Lightweight design improves turbo response time

Vibration Damping: Minimizes harmonic resonance in high-RPM operation

Quality Assurance & Testing

Every housing undergoes rigorous validation:

X-ray inspection for internal defect detection

Helium mass spectrometer leak testing

Dimensional verification using optical CMM

Pressure testing to 2x operational requirements

Material composition certification

Industry Applications

Automotive Turbochargers: Gasoline and diesel engine applications

Aerospace Auxiliary Power Units: Lightweight turbine systems

Industrial Compressors: Process gas and air handling systems

Marine Propulsion: High-output diesel turbocharging

Our technical engineering team works closely with clients to optimize housing designs for specific airflow requirements, ensuring maximum compressor efficiency and reliability. By leveraging our aluminum casting expertise, manufacturers achieve the perfect balance between performance, durability, and cost-effectiveness in their turbine systems.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |