- Overzicht

- Aanbevolen producten

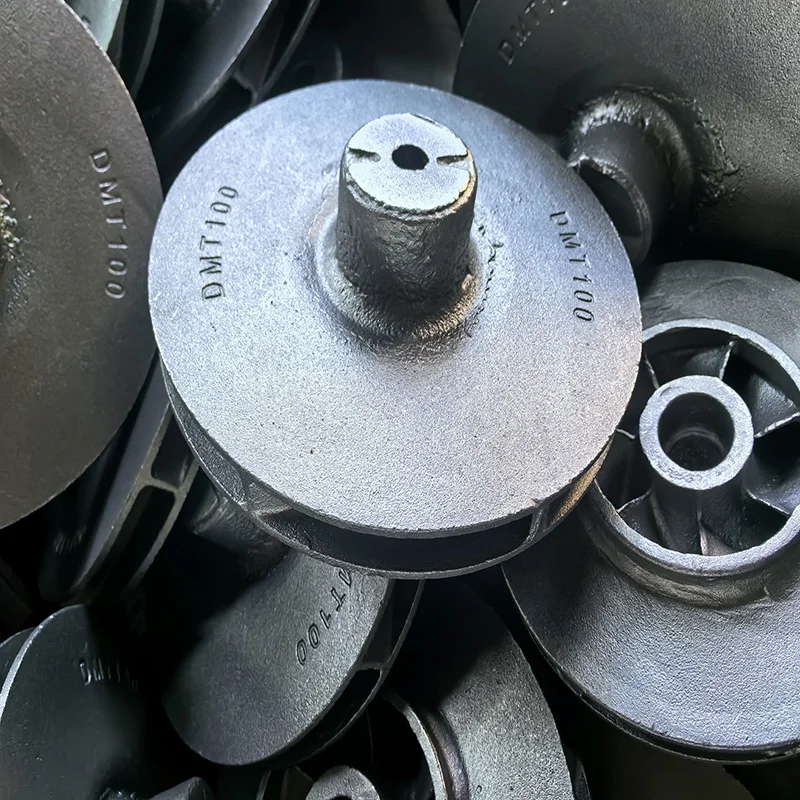

In de sector van het uitgeven van dranken zorgen precisie gietwerkzaamheden in roestvrij staal voor uitzonderlijke kwaliteitsonderdelen voor bierkraanlichamen en wijnkranen. Deze cruciale uitgiftecomponenten vereisen strenge normen qua materiaalzuiverheid, oppervlakteafwerking en dimensionale nauwkeurigheid om optimale prestaties te garanderen in commerciële en residentiële toepassingen. Onze gespecialiseerde gietexpertise levert kraanlichamen die esthetische uitstraling combineren met functionele uitmuntendheid.

Geavanceerde materiaalspecificaties

Onze bierkraan- en wijnkraanafgietsels zijn vervaardigd uit roestvrij staal van voedselkwaliteit, speciaal samengesteld voor toepassingen waarbij het in contact komt met dranken. De roestvrijstalen kwaliteiten SS304L en SS316L bieden uitzonderlijke corrosiebestendigheid tegen zure dranken, reinigingsmiddelen en milieublootstelling -7. Deze laagkoolstofvarianten (meestal minder dan 0,08% koolstofgehalte) voorkomen carbide-uitslag tijdens las- en gietprocessen, wat zorgt voor een constante materiaalintegriteit -4. Het chroomgehalte (18-20%) creëert een passieve oxide laag die oxidatie weerstaat en hygiënische oppervlakken behoudt, terwijl nikkel (8-12%) de austenitische structuur stabiliseert voor verbeterde duurzaamheid -4.

Nauwkeurige productieprocessen

Ons spuitgietproces (verloren was) levert kraandonderdelen met uitzonderlijke dimensionale nauwkeurigheid en oppervlaktekwaliteit -1-5. De methode begint met spuitgegoten wax patronen die de ingewikkelde interne en externe geometrieën van kraanlichamen exact repliceren -4. Deze patronen ondergaan meerdere toepassingen van keramische coating, waardoor een robuuste schaalvorm ontstaat die bestand is tegen de extreme temperaturen van gesmolten roestvrij staal -4.

Het gietproces maakt gebruik van geavanceerde toevoersystemen die zorgen voor volledige vulinstantie van de mal en turbulentie minimaliseren, waardoor defectvorming op kritieke afdichtingsoppervlakken wordt voorkomen -4. Na het gieten worden de componenten gepreciseerd bewerkt om draadprofielen, afdichtingsvlakken en montage-oppervlakken te verfijnen, met toleranties binnen ±0,02 mm voor perfecte montagecompatibiliteit -1. De laatste productiefasen omvatten speciale oppervlaktebehandelingen zoals spiegelglanspolijsten, geborsteld polijsten en elektropolijsten om hygiënische, eenvoudig te reinigen oppervlakken te creëren met ruwheidswaarden tot zo laag als Ra 0,8μm -5.

Verbeterde Prestatiekenmerken

Biertappers en wijnkranen die via onze processen worden vervaardigd, leveren:

Superieure corrosieweerstand: Bestand tegen langdurige blootstelling aan zure wijnen, gekoolzuurde bieren en alkalische reinigingsoplossingen zonder achteruitgang -7

Uitstekende mechanische eigenschappen: Hoge treksterkte (tot 85.000 psi) en hardheid behouden de dimensionele stabiliteit bij herhaald gebruik -9

Optimale hygiëne: Niet-poreuze oppervlakken voorkomen bacteriële kolonisatie en vergemakkelijken het reinigen -7

Temperatuurbestendigheid: Behoudt structurele integriteit over het gehele bereik van drankenservice-temperaturen, van gekoeld tot omgevingsomstandigheden -9

Lange levensduur: Uitzonderlijke slijtvastheid zorgt voor betrouwbare prestaties gedurende uitgebreide gebruikscycli

Kwaliteitsborging en Compliance

Onze productieprocessen omvatten strenge kwaliteitsprotocollen specifiek voor dranktoepassingen:

Materiaalcertificering: Verificatie van roestvrijstaal van voedselkwaliteit volgens internationale normen -1

Afmetingsvalidatie: Controle van kritieke interfaces en afdichtingsoppervlakken met een coördinatenmeetmachine (CMM) -1

Oppervlakteafwerkinganalyse: Profilometerverificatie om naleving te waarborgen van hygiëne-eisen voor oppervlakken -5

Druktest: Validering van de integriteit van vloeistofbehoud onder operationele omstandigheden -4

Schoonheidverificatie: Testen op resterende verontreinigingen om zuiverheidsbescherming van dranken te waarborgen

Technische Toepassingsexpertise

Onze gietdiensten ondersteunen diverse toepassingen voor drankendistributie:

Commerciële tapinstallaties

Barfonteinen die duurzaamheid vereisen onder zware gebruiksomstandigheden

Meertoreninstallaties die consistente dimensionele kenmerken nodig hebben

Direct-aanvoersystemen die precisiebewerkte aansluitingen vereisen

Specialiteitsdranktoepassingen

Wijndistributiekranen met nauwkeurige stroomregelkenmerken

Ambachtbierhendels die esthetische uitstraling combineren met functionele betrouwbaarheid

Krathendelmontageonderdelen die lekvrije werking onder druk garanderen

Hygiënische Ontwerpoplossingen

Naadloze binnenopeningen die bacteriële ophoping in complexe geometrieën voorkomen

Afgeronde hoeken en vloeiende overgangen die effectief reinigen vergemakkelijken

Optimalisatie van oppervlakken voor contact met levensmiddelen, voldoende aan internationale hygiënestandaarden

Voordelen van Industriële Samenwerking

Wij bieden uitgebreide technische ondersteuning aan fabrikanten van drankapparatuur:

Ontwerp voor Fabricage: Optimalisatie van kraanlichaamgeometrieën voor zowel gietefficiëntie als stromingsdynamica

Begeleiding bij Materiaalkeuze: Aanbevelen van geschikte roestvrijstalen kwaliteiten voor specifieke dranktypes

Snelle Prototypenontwikkeling: Versnellen van productontwikkelingscycli via snelle patroonproductie

Productieschaalvergroting: Ondersteuning van eisen variërend van initiële prototypen tot massaproductie

Onze diensten |

Nauwkeurig CNC-frezen, Nauwkeurig CNC-draaien Snel prototypen Plastic injectievorm Metaalstansen, Gietvormen, Silicon- en rubbergietvorm, Aluminiumextrusie, Mouwproductie, enz. |

Materiaal |

Aluminiumlegering: 5052/6061/6063/7075 enz. Messinglegering: 3602/2604/h59/h62/enz. Rostbestendige staallegering: 303/304/316/412/enz. Staallegering: Koolstof/Gietstaal/enz. Andere speciale materialen: Lucite/Nylon/Bakelite/etc Plastic, Hout, Silicone, Rubber, Of zoals gewenst door de klant |

Oppervlaktebehandeling |

Anodiseren, Zandstralen, Verfjen, Poedercoating, Elektroplaten, Sijpel Drukken, Borstelen, Polijsten, Lasergraveerderij... |

Tekeningformaat |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl,etc |

Service Project |

Ontwerp, productie en technische dienstverlening, ontwikkeling en vervaardiging van modellen, enz. |

Testmachine |

Digitale hoogtemeter, schermmeter, driedimensionale meetmachine, projectiemachine, ruwheidstester, hardheidstester enz. |

Kwaliteitsborging |

ISO9001:2015 gecertificeerd TUV |

Verpakking |

Schuim, karton, houten dozen, of zoals de klant vereist |

Leveren |

DHL, FEDEX, UPS, TNT, EMS, SF Of volgens klantenspecificatie |