- Overview

- Recommended Products

In the competitive appliance manufacturing industry, the quality and performance of core components define product excellence. Our professional factory offers specialized casting services dedicated to producing customized gas stove parts for OEM partners. We leverage advanced casting technologies and stringent quality control to deliver components that meet precise specifications for durability, efficiency, and aesthetic appeal.

Premium Materials for Superior Performance

We select materials based on the functional requirements of each stove part, primarily utilizing:

Die-Cast Aluminum Alloys (e.g., A380, ADC12): Ideal for burner caps, valve bodies, and ignition covers. These alloys offer an excellent strength-to-weight ratio, superior heat dissipation, and good corrosion resistance, ensuring consistent performance under repeated thermal cycling.

Gray Iron (Class 25-35): Used for heavy-duty components like stove grates, base frames, and support bodies. Gray iron provides exceptional heat resistance, high compressive strength, and outstanding wear resistance, maintaining structural integrity under high temperatures and daily use.

Advanced Casting and Finishing Processes

Our manufacturing process is tailored to achieve high precision and surface quality:

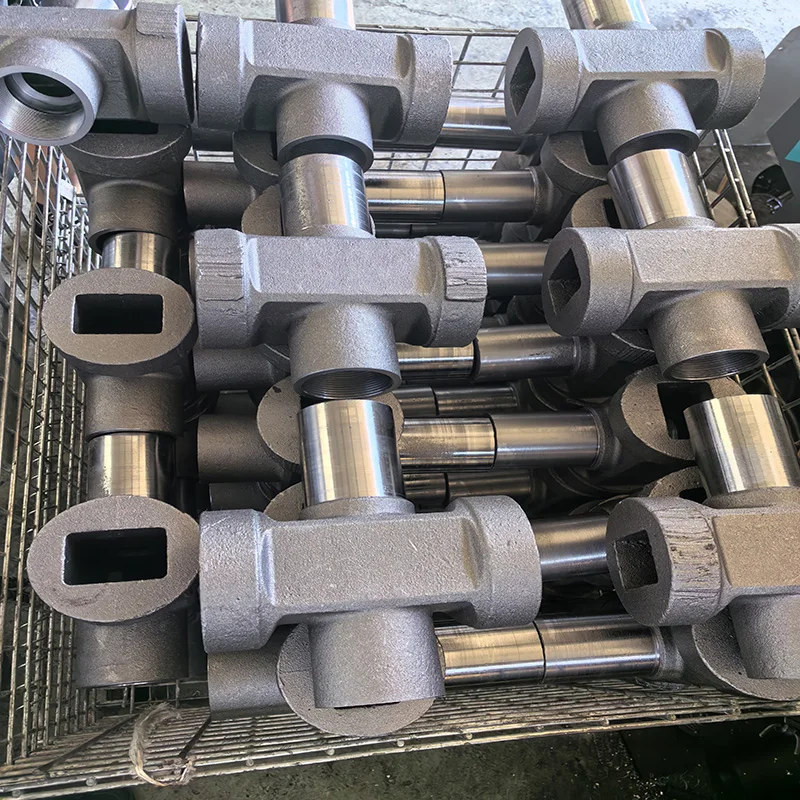

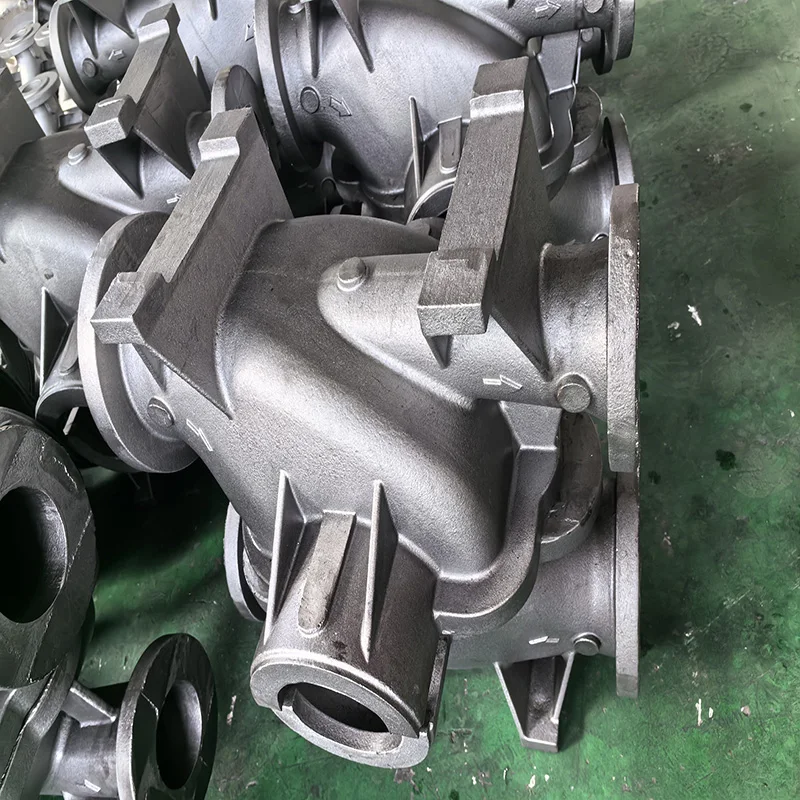

High-Pressure Die Casting: For aluminum parts, this process ensures rapid production of complex shapes with thin walls, excellent dimensional stability, and smooth surfaces—critical for burner efficiency and aesthetic details.

Resin Sand Casting: Applied for iron parts like grates and frames, this method allows for high-dimensional accuracy and superior surface finish, accommodating intricate designs and heavy-section castings.

Precision Machining: Critical mating surfaces and mounting points are machined to ensure perfect fit and alignment during assembly.

Surface Treatment: Parts undergo specialized finishing, including high-temperature powder coating, enamel coating, or polishing, to enhance corrosion resistance, ease of cleaning, and visual appeal.

Comprehensive Range of Gas Stove Components

Our customized gas stove parts are engineered for a wide variety of applications, including:

Burner Caps and Heads

Stove Grates and Pan Supports

Valve Bodies and Control Knobs

Oven Door Hinges and Frames

Base Plates and Manifolds

As a dedicated professional factory, we provide end-to-end solutions from prototyping to mass production. Partner with us for reliable, high-performance casting services that enhance the safety, efficiency, and marketability of your gas stove products.

Our Services |

CNC Precision Milling Machining,CNC Precision Turning Machining, Rapid Prototyping Plastic Injection Mould Metal Stamping, Die Casting, Silicone And Rubber Mould, Aluminum Extrusion, Mould Fabrication,etc |

Material |

Aluminum Alloy:5052/6061/6063/7075 etc Brass Alloy: 3602/2604/h59/h62/etc Stainless Steel Alloy: 303/304/316/412/etc Steel Alloy: Carbon/Die Steel/etc Other Special Materials: Lucite/Nylon/Bakelite/etc Plastic, Wood, Silicone, Rubber,Or as per the customers’ requirements |

Surface Treatment |

Anodizing, Sandblasting, Painting, Powder coating, Electroplating, Silk Printing, Brushing, Polishing, Laser Engraving... |

Drawing Format |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl,etc |

Service Project |

To provide project design, production and technical service, mould development and fabrication, etc |

Testing Machine |

Digital Height Gauge, caliper, Three Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

Quality Assurance |

ISO9001:2015 Certified TUV |

Packing |

Foam, Carton, Wooden boxes, or as per the customer’s requirements |

Deliver |

DHL, FEDEX, UPS, TNT, EMS, SF Or according to customers′ requirement |