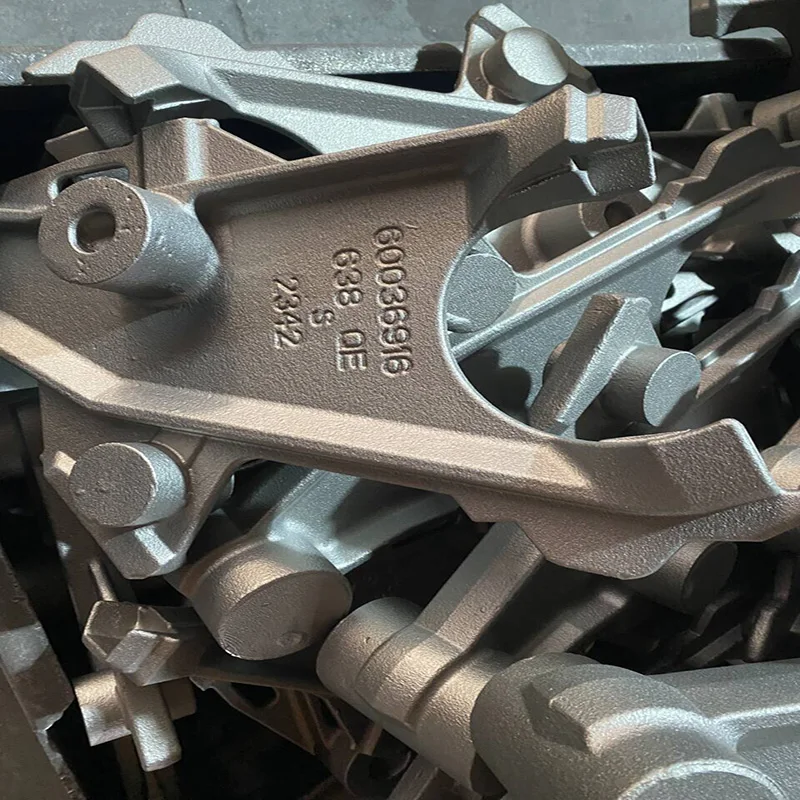

Premium Casting Services Stainless Steel and Carbon Steel Butterfly Valve High Quality Product

- Overview

- Recommended Products

As a specialized manufacturer in fluid control components, we provide premium casting services for stainless steel and carbon steel butterfly valves that meet the most demanding industrial standards. Our manufacturing expertise combines advanced casting technology with precision engineering to deliver butterfly valves that ensure reliable performance, exceptional durability, and optimal flow control in various fluid handling applications.

Material Excellence and Performance Characteristics

We utilize high-grade stainless steel (304, 316, 316L grades) and carbon steel (WCB, WCC grades) specifically engineered for butterfly valve applications. Our stainless steel valves offer excellent corrosion resistance with tensile strength of 515-620 MPa, making them ideal for aggressive media and corrosive environments. The carbon steel variants provide superior mechanical strength with tensile strength of 485-655 MPa, ensuring reliable performance in high-pressure applications. These materials demonstrate:

Exceptional resistance to pitting and crevice corrosion

Excellent mechanical properties across temperature ranges

Superior wear resistance for long service life

Good machinability for precision component manufacturing

Reliable performance under cyclic loading conditions

Advanced Casting Manufacturing Process

Our production methodology employs sophisticated casting techniques optimized for valve components:

Investment Casting Technology

We utilize precision investment casting that enables production of complex valve body geometries with exceptional dimensional accuracy. This advanced process ensures:

Superior surface finish quality (Ra 3.2-6.3 μm)

Tight dimensional tolerances (±0.13 mm per 25 mm)

Minimal machining requirements and material waste

Consistent reproduction of intricate flow passages

Sand Casting Capabilities

For larger valve sizes and specific applications, we employ resin sand casting technology that delivers:

Cost-effective production of valve bodies

Excellent structural integrity

Flexibility in design modifications

Suitable for various production volumes

Quality Assurance and Performance Validation

Each butterfly valve undergoes rigorous quality control:

Pressure testing to API 598 standards

Material composition verification through spectrochemical analysis

Dimensional validation using coordinate measuring machines

Surface inspection for defect detection

Mechanical property testing confirming specifications

Industrial Applications and Solutions

Our premium cast butterfly valves serve diverse applications:

Water Treatment Plants: Control valves and isolation valves

Chemical Processing: Corrosion-resistant valves for aggressive media

Oil and Gas Industry: High-pressure valves for pipeline applications

Power Generation: Main steam and auxiliary system valves

Marine Applications: Seawater-resistant valves and shipboard systems

By combining advanced casting technology with comprehensive quality assurance, we deliver butterfly valves that provide reliable performance, extended service life, and optimal flow control efficiency. Our engineering team works closely with clients to develop customized valve solutions that meet specific application requirements, ensuring perfect performance, superior quality, and cost-effective operation in various industrial fluid handling systems.

OEM Service |

Investment Casting |

Die Casting |

Sand Casting |

Stamping/Forging |

||||

Weight |

5g-50kg |

0.5kg-1000kg |

0.5kg-1ton |

|||||

Capacity |

200ton/month |

500ton/month |

1000ton/month |

200ton/month |

||||

Machining tolerance |

±0.01-0.03mm |

±0.02mm |

||||||

Surface roughness |

6.4 Raum/254 Rauinches |

3.2 Raum/125 Rauinches |

12.5 Raum |

|||||

MOQ |

200 pcs |

1000 pcs |

200 pcs |

1000 pcs |

||||

Material for cast |

304 316 stainless steel carbon steel |

A380 A356 aluminum aluminum alloy zinc alloy |

Iron grey iron ductile iron aluminum |

Stainless aluminum brass carbon steel |

||||

Add-Value Service |

Add-Value Service |

|||||||

Coating |

Anodizing Zinc plating |

Paining |

Powder coating |

Electroplating |

||||

Machining |

Machining |

Milling |

Drilling |

Boring |

||||

Cutting&Forming |

Key cutting |

EDM |

Welding |

|||||

Heat Treatment |

Hardening |

Normalizing |

Quenching&Tempering |

Annealing |

||||