- Overview

- Recommended Products

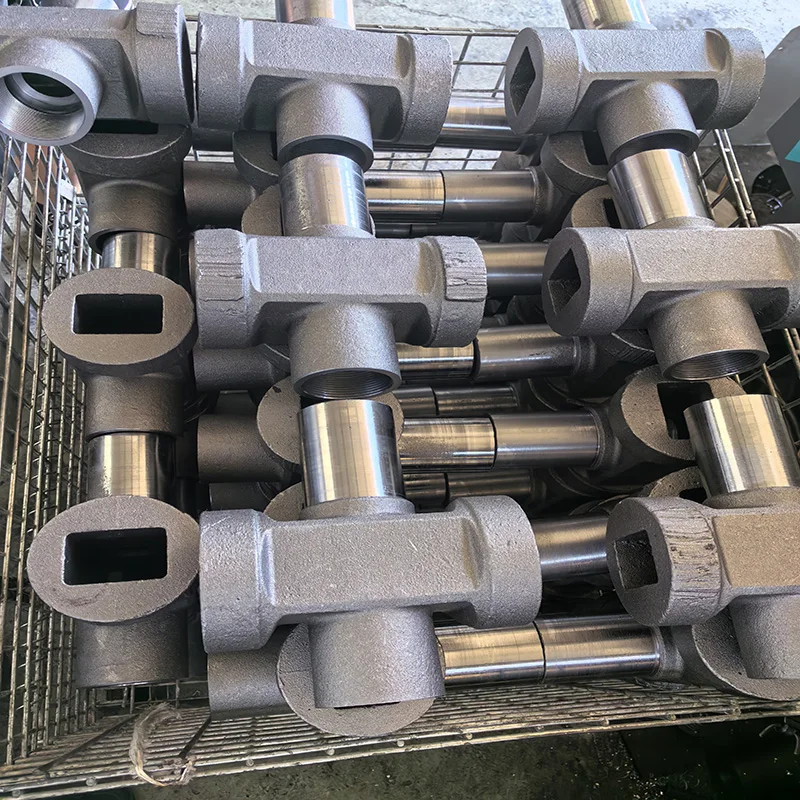

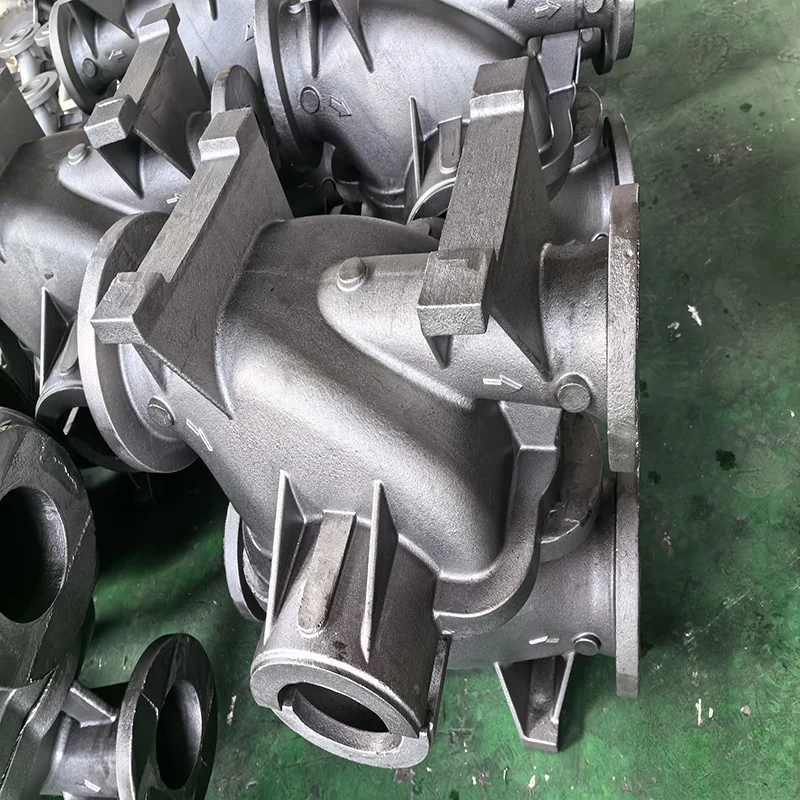

Premium Casting Solutions Direct from Chinese Manufacturing Hub

As a leading OEM manufacturer based in China, we provide comprehensive stainless steel and gray iron casting services delivered directly from our state-of-the-art production facility. Our factory-direct approach ensures competitive pricing while maintaining international quality standards, offering global clients reliable casting solutions with complete supply chain control.

Advanced Material Selection and Properties

We specialize in high-performance materials for diverse industrial applications:

Stainless Steel Casting Grades:

304/L Stainless Steel: Excellent general corrosion resistance and good mechanical properties

316/L Stainless Steel: Superior chloride resistance and enhanced strength at elevated temperatures

410 Stainless Steel: Good wear resistance and mechanical properties with heat treatment capability

Duplex Stainless Steel: Combined strength and corrosion resistance for demanding environments

Gray Iron Casting Grades:

Grade G2500: Tensile strength 250 MPa, ideal for general machinery components

Grade G3000: Tensile strength 300 MPa, suitable for automotive and hydraulic applications

Grade G3500: Enhanced strength (350 MPa) for pressure-containing parts

Grade G4000: Premium grade (400 MPa) for high-stress applications

Manufacturing Excellence and Process Innovation

Our integrated manufacturing processes ensure superior quality:

Pattern Making:

CAD/CAM designed patterns with precision machining

Rapid prototyping using 3D printing technology

Modular pattern systems for flexible production

Quality verification using CMM inspection

Casting Processes:

Resin sand casting for complex geometries and superior surface finish

Shell molding technology for high-volume production

Green sand casting for cost-effective manufacturing

Investment casting for intricate stainless steel components

Quality Control:

Spectrochemical analysis for precise composition control

Real-time process monitoring throughout production

Non-destructive testing including RT, UT, and MT

Dimensional verification per customer specifications

Enhanced Performance Characteristics

Our cast components deliver exceptional operational benefits:

Corrosion resistance suitable for various industrial environments

Excellent mechanical properties with consistent performance

Superior surface finish reducing machining requirements

Pressure tightness for fluid handling applications

Good machinability and weldability for secondary processing

Thermal stability across wide temperature ranges

Technical Specifications and Capabilities

Component weight range: 1 kg to 2000 kg

Dimensional tolerance: CT8 to CT12 per ISO 8062

Surface finish: Ra 12.5 to 50 μm as-cast

Annual production capacity: 10,000 tons

Lead time: 4-8 weeks for production orders

Global Applications and Industry Served

Automotive components and transportation systems

Industrial machinery and equipment manufacturing

Valve and pump manufacturing for various industries

Construction and mining equipment components

Food processing and pharmaceutical machinery

Quality Assurance and Certification

ISO 9001:2015 Quality Management System

ISO 14001 Environmental Management System

Material certifications per ASTM/EN standards

Complete traceability from raw material to finished product

Third-party inspection acceptance

Competitive Advantages

Direct factory pricing with no intermediary margins

20+ years of specialized casting experience

Comprehensive engineering and technical support

Flexible order quantities from prototypes to mass production

Reliable delivery performance with global logistics support

Our factory-direct OEM services combine advanced manufacturing capabilities with stringent quality control, delivering stainless steel and gray iron castings that meet the most demanding international standards. By maintaining complete control over our production processes and supply chain, we ensure consistent quality, competitive pricing, and reliable delivery for global clients across multiple industries.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |