OEM Customized Cast Iron Ductile Iron Sand Casting Foundry High Quality Casting Services Product

- Overview

- Recommended Products

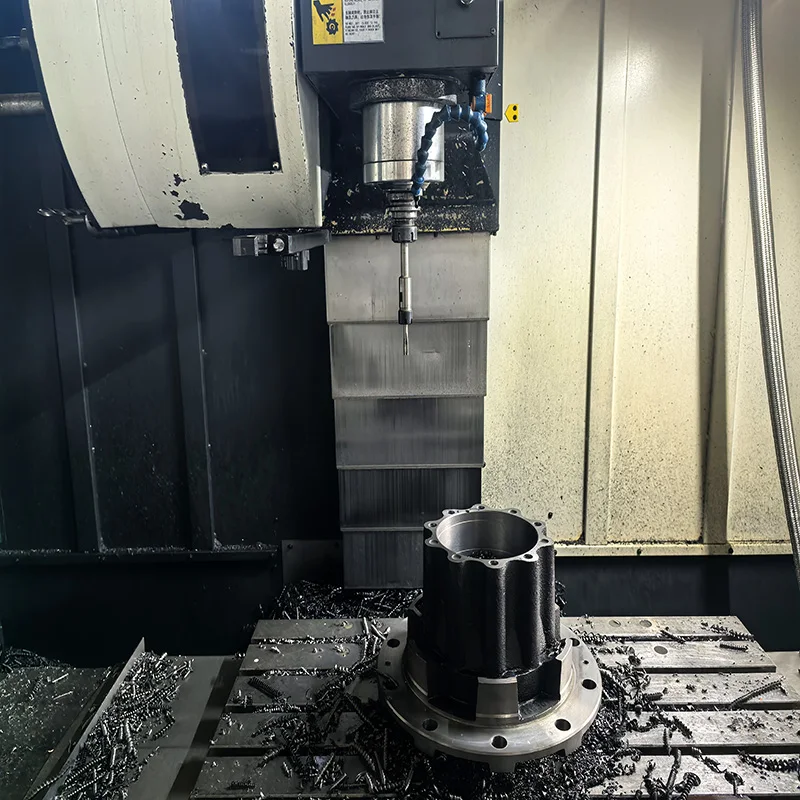

As a specialized OEM sand casting foundry, we deliver high-quality customized castings in gray iron and ductile iron for diverse industrial applications. Our expertise combines traditional foundry craftsmanship with modern technology to produce components that meet precise specifications while ensuring optimal performance, durability, and cost-efficiency for volume production.

Material Excellence and Metallurgical Precision

We specialize in engineering-grade iron castings with certified material properties:

Gray Iron Castings (ASTM A48 Class 25B-40B): Delivering excellent vibration damping, machinability, and compressive strength for structural applications

Ductile Iron Castings (ASTM A536 60-40-18, 65-45-12, 80-55-06): Providing superior tensile strength, impact resistance, and elongation characteristics through controlled nodularization treatment

Alloyed Iron Variations: Special grades with nickel, chromium, or molybdenum additions for enhanced wear/corrosion resistance or elevated temperature performance

All melts are controlled through spectral analysis with full material certification and mechanical property verification.

Advanced Sand Casting Manufacturing Process

Our comprehensive production capabilities ensure consistent quality:

-

Pattern Manufacturing

CNC-machined wood, epoxy, or metal patterns

3D printed prototypes for design validation

Custom core box design and fabrication

-

Molding Technology

Automated green sand molding lines for high-volume production

Resin sand molding for complex geometries and improved surface finish

Shell molding for thin-walled components requiring dimensional precision

-

Casting & Finishing

Controlled pouring with degassing and inoculation treatment

Shakeout, cutting, and shot blasting operations

Heat treatment: annealing, normalizing, quenching, and tempering

-

Quality Assurance

Dimensional inspection with CMM and layout equipment

Ultrasonic and mechanical property testing

Microstructural analysis and hardness testing

Pressure testing and non-destructive examination

Performance Advantages

Design Flexibility: Accommodating complex geometries and custom requirements

Cost-Effective Production: Competitive pricing for medium to high-volume orders

Superior Mechanical Properties: Consistent strength, hardness, and wear characteristics

Reliable Performance: Proven durability in demanding applications

Technical Support: Engineering assistance from design to production

Industry Applications

Automotive and commercial vehicle components

Agricultural and construction machinery parts

Pump and valve bodies for fluid handling systems

Heavy equipment and industrial machinery

General engineering and custom applications

Our OEM-focused approach ensures seamless integration with your supply chain, supported by comprehensive quality documentation and on-time delivery performance. We maintain IATF 16949 and ISO 9001 quality systems with full material traceability. Contact our technical team to discuss your specific casting requirements and benefit from our foundry expertise for your next project.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |