- Overview

- Recommended Products

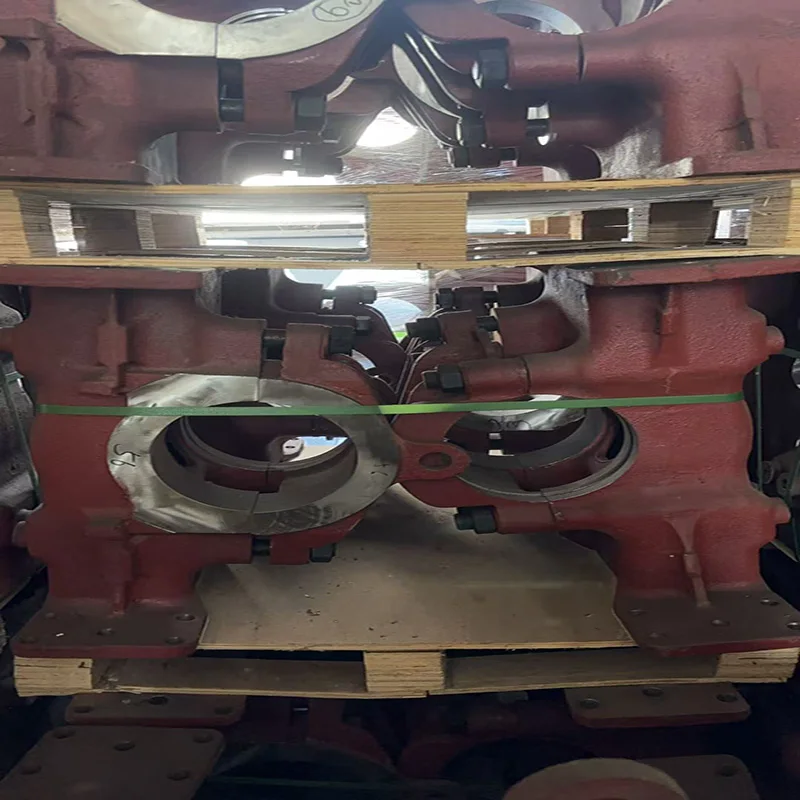

As a trusted manufacturer of automotive components, we specialize in producing OEM 4806826070 and 4806826071 suspension parts through advanced casting technologies. These critical suspension components are engineered to meet rigorous quality standards, ensuring optimal performance and durability for modern vehicles.

Advanced Materials and Superior Performance

Our suspension parts are manufactured using high-grade materials, including:

Ductile iron (65-45-12 grade) for exceptional strength and impact resistance

A356-T6 aluminum alloy for optimal strength-to-weight ratio

4140 alloy steel for high fatigue strength and durability

These materials undergo specialized heat treatment processes to enhance their mechanical properties. The resulting components demonstrate:

Yield strength exceeding 275 MPa

Excellent corrosion resistance

Superior fatigue life under cyclic loading conditions

Maintained dimensional stability across temperature variations

Precision Manufacturing Process

We employ sophisticated casting techniques to ensure component integrity:

Pattern Design: Utilization of CAD/CAM systems for precision mold creation

Sand Casting Process: Employing resin-bonded sand molds for complex geometries

Investment Casting: For components requiring superior surface finish

Quality Control: Implementation of X-ray inspection and magnetic particle testing

Our production process includes:

Controlled melting in induction furnaces

Automated pouring systems for consistency

CNC machining for critical tolerances

Comprehensive material certification

Critical Automotive Applications

These suspension parts serve essential functions in:

Front suspension control arms

Steering knuckles and mounting brackets

Wheel hub connectors

Shock absorber mounting points

Industry Compliance and Certification

All components are manufactured according to:

IATF 16949 quality standards

ISO 9001:2015 requirements

RoHS compliance for environmental safety

Our suspension parts undergo rigorous testing, including:

Salt spray testing (500+ hours)

Fatigue testing (1 million+ cycles)

Dimensional validation with CMM

Technical Advantages

Weight reduction up to 30% compared to conventional components

Improved vibration damping characteristics

Enhanced corrosion protection

Consistent performance in extreme conditions

By combining advanced metallurgy with precision casting techniques, we deliver suspension components that exceed OEM specifications while providing reliable performance throughout the vehicle's service life. Our commitment to quality ensures these parts maintain structural integrity under the most demanding operating conditions, contributing to enhanced vehicle safety and driving dynamics.

Our Services |

CNC Precision Milling Machining,CNC Precision Turning Machining, Rapid Prototyping Plastic Injection Mould Metal Stamping, Die Casting, Silicone And Rubber Mould, Aluminum Extrusion, Mould Fabrication,etc |

Material |

Aluminum Alloy:5052/6061/6063/7075 etc Brass Alloy: 3602/2604/h59/h62/etc Stainless Steel Alloy: 303/304/316/412/etc Steel Alloy: Carbon/Die Steel/etc Other Special Materials: Lucite/Nylon/Bakelite/etc Plastic, Wood, Silicone, Rubber,Or as per the customers’ requirements |

Surface Treatment |

Anodizing, Sandblasting, Painting, Powder coating, Electroplating, Silk Printing, Brushing, Polishing, Laser Engraving... |

Drawing Format |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl,etc |

Service Project |

To provide project design, production and technical service, mould development and fabrication, etc |

Testing Machine |

Digital Height Gauge, caliper, Three Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

Quality Assurance |

ISO9001:2015 Certified TUV |

Packing |

Foam, Carton, Wooden boxes, or as per the customer’s requirements |

Deliver |

DHL, FEDEX, UPS, TNT, EMS, SF Or according to customers′ requirement |