- Overview

- Recommended Products

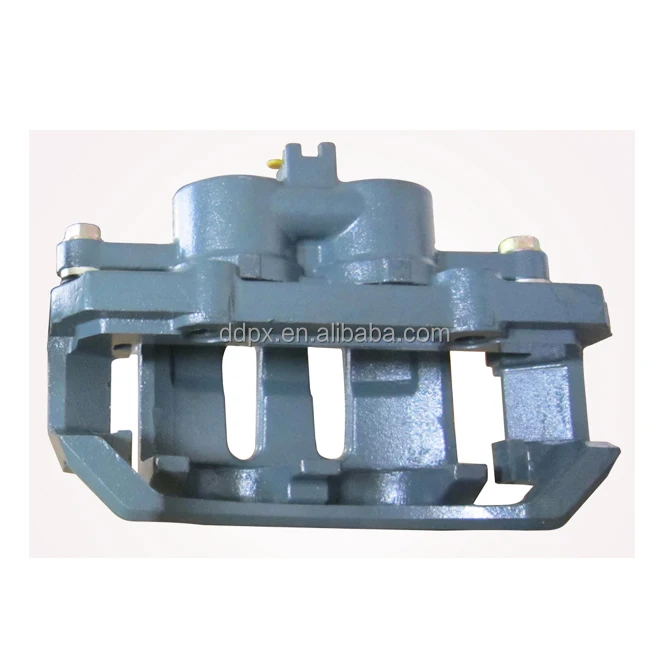

In automotive safety systems, brake calipers play a crucial role in ensuring reliable stopping power and vehicle control. The OEM 4101110G01 brake caliper represents precision engineering at its finest, designed to meet strict original equipment manufacturer standards for performance, durability, and safety. This critical braking component combines advanced materials with sophisticated manufacturing processes to deliver exceptional performance under diverse driving conditions, making it the ideal choice for vehicle maintenance and repair.

Material Excellence and Construction

High-Strength Gray Cast Iron: Provides excellent vibration damping and thermal stability

Premium Aluminum Alloy: Used in specific models for weight reduction and corrosion resistance

Heat-Treated Piston: Hardened to 45-50 HRC for wear resistance

Anti-Corrosion Coating: Multi-layer surface protection for extended service life

Advanced Manufacturing Process

-

Precision Casting Technology

Automated molding systems ensuring consistent dimensional accuracy

Controlled solidification process preventing internal defects

Real-time quality monitoring during production

-

CNC Machining Operations

5-axis machining centers maintaining tolerances within ±0.02mm

Precision boring of piston cylinders and sliding pin holes

Automated threading for bleed screws and fluid ports

-

Quality Validation

Hydrostatic pressure testing at 3000 PSI

100% functional testing of piston movement

Dimensional verification using optical measurement systems

Performance Characteristics

Thermal Management: Withstands continuous operation temperatures up to 300°C

Structural Integrity: Tested to withstand 1.5 million pressure cycles

Corrosion Resistance: Salt spray testing exceeding 500 hours

Sealing Performance: Zero leakage under extreme pressure conditions

Technical Specifications

Piston Diameter: Precision-matched to vehicle requirements

Mounting Configuration: Direct OEM replacement

Fluid Compatibility: Suitable for DOT 3, DOT 4, and DOT 5.1

Surface Finish: Powder-coated or electroplated per OEM specification

Applications and Compatibility

Original Equipment Replacement

Commercial Vehicle Applications

Aftermarket Service and Repair

Fleet Maintenance Operations

Ensure your vehicle's braking system performance with the OEM 4101110G01 brake caliper. Manufactured to exacting standards and backed by comprehensive quality assurance, it delivers the reliability and safety that modern vehicles demand. Contact us for technical specifications and availability information.

Our Services |

CNC Precision Milling Machining,CNC Precision Turning Machining, Rapid Prototyping Plastic Injection Mould Metal Stamping, Die Casting, Silicone And Rubber Mould, Aluminum Extrusion, Mould Fabrication,etc |

Material |

Aluminum Alloy:5052/6061/6063/7075 etc Brass Alloy: 3602/2604/h59/h62/etc Stainless Steel Alloy: 303/304/316/412/etc Steel Alloy: Carbon/Die Steel/etc Other Special Materials: Lucite/Nylon/Bakelite/etc Plastic, Wood, Silicone, Rubber,Or as per the customers’ requirements |

Surface Treatment |

Anodizing, Sandblasting, Painting, Powder coating, Electroplating, Silk Printing, Brushing, Polishing, Laser Engraving... |

Drawing Format |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl,etc |

Service Project |

To provide project design, production and technical service, mould development and fabrication, etc |

Testing Machine |

Digital Height Gauge, caliper, Three Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

Quality Assurance |

ISO9001:2015 Certified TUV |

Packing |

Foam, Carton, Wooden boxes, or as per the customer’s requirements |

Deliver |

DHL, FEDEX, UPS, TNT, EMS, SF Or according to customers′ requirement |