- Overview

- Recommended Products

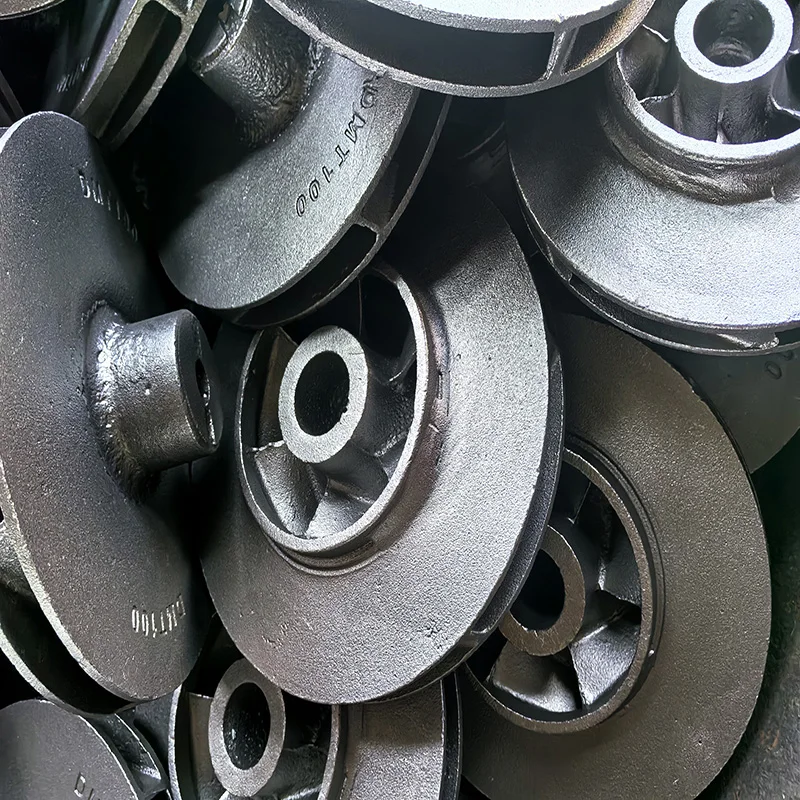

Our multifunctional electric sewing machine head casting services deliver superior components for the evolving textile industry. Utilizing advanced casting technologies and premium materials, we manufacture sewing machine heads that combine precision, durability, and operational excellence. These critical components form the foundation of modern sewing equipment, ensuring smooth operation and long-term reliability in demanding production environments.

Advanced Material Selection

We employ specialized aluminum and zinc alloys specifically engineered for sewing machine applications:

ADC12 Aluminum Alloy: Excellent fluidity and strength-to-weight ratio

ZA-8 Zinc Alloy: Superior dimensional stability and wear resistance

A380 Aluminum Alloy: Optimal balance of mechanical properties and castability

Custom Alloy Blends: Tailored compositions for specific performance requirements

Sophisticated Manufacturing Process

Our comprehensive production system integrates multiple advanced technologies:

High-Pressure Die Casting Process

Precision Mold Design: CAD/CAM engineered tooling with temperature control systems

Automated Injection: 800-1200 ton clamping force with controlled fill parameters

Rapid Solidification: Optimized cooling channels for consistent microstructure

Automated Trimming: Robotic flash removal and gate separation

Secondary Processing

CNC machining of critical bearing and shaft surfaces

Precision drilling and tapping for component mounting

Surface grinding for optimal flatness and alignment

Vibration finishing for smooth operation

Quality verification at each processing stage

Enhanced Performance Characteristics

Dimensional Accuracy: ±0.1mm tolerance on critical dimensions

Surface Quality: Ra 1.6-3.2μm achievable on functional surfaces

Mechanical Strength: 240-320 MPa tensile strength range

Vibration Resistance: Excellent damping characteristics for smooth operation

Weight Optimization: Balanced design for operator comfort and stability

Thermal Stability: Maintains precision under continuous operation

Quality Assurance Excellence

Material certification and traceability

X-ray inspection for internal integrity

CMM dimensional verification

Hardness testing and mechanical validation

Performance testing under simulated operating conditions

Statistical process control throughout manufacturing

Application Versatility

Our casting services support diverse sewing machine types:

Industrial Overlock Machines: High-speed production equipment

Household Sewing Machines: Compact and lightweight designs

Embroidery Machines: Precision components for intricate stitching

Specialty Stitching Equipment: Heavy-duty industrial applications

Computerized Sewing Systems: Integrated electronic component mounting

Technical Advantages

Reduced vibration transmission for smoother operation

Enhanced heat dissipation during continuous use

Superior wear resistance in high-movement areas

Optimal weight distribution for operator comfort

Excellent compatibility with modern drive systems

Long-term dimensional stability

Customization Capabilities

Size range from 150mm to 600mm main body dimensions

Multiple mounting configurations and interface options

Custom reinforcement for specific load requirements

Integrated component housing designs

Special surface treatments and finishes

Our multifunctional electric sewing machine head casting services represent the perfect fusion of traditional craftsmanship and modern manufacturing technology. With rigorous quality control and deep understanding of textile equipment requirements, we deliver components that ensure reliable performance, extended service life, and superior stitching quality for both industrial and domestic sewing applications.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |