Hot Selling New Truck Loading Stainless Steel Hydraulic Cylinders Double Acting Skip Loader Trailer Truck Lifting Ram

- Overview

- Recommended Products

In the demanding world of commercial transportation and material handling, efficiency and durability are paramount. Our hot-selling new Truck Loading Stainless Steel Hydraulic Cylinders, specifically designed as double-acting skip loader and trailer truck lifting rams, are engineered to meet these critical demands. This article delves into the professional aspects of these cylinders, exploring their superior material composition, exceptional performance, advanced manufacturing process, and broad applications.

Superior Material: Corrosion-Resistant Stainless Steel

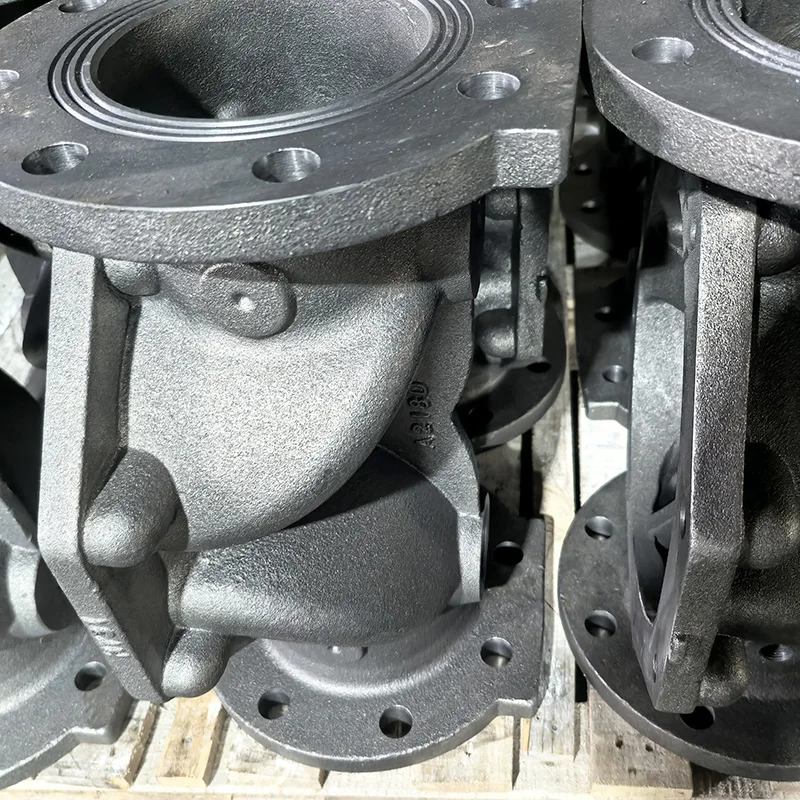

The core of these hydraulic cylinders is their construction from high-grade stainless steel. Unlike standard carbon steel cylinders, the stainless steel body and piston rod offer exceptional resistance to corrosion, rust, and pitting. This is crucial for equipment exposed to harsh weather conditions, road salts, and various chemicals, significantly extending the service life and reducing maintenance costs.

Exceptional Performance & Design

These are double-acting cylinders, meaning they generate powerful force in both extension and retraction strokes. This allows for precise control during both the lifting and lowering of skip loaders and trailer beds. Key performance features include:

High Load Capacity: Engineered to handle heavy loads with stability and safety.

Robust Sealing System: Integrated with high-quality seals to prevent hydraulic fluid leakage, ensuring consistent performance and environmental safety.

Smooth Operation: Precision machining ensures minimal friction, leading to smoother operation and reduced wear.

Advanced Manufacturing & Quality Control

Our cylinders are not just products; they are results of sophisticated production techniques. The manufacturing process involves Computer Numerical Control (CNC) machining for pinpoint accuracy on all components. Each cylinder undergoes rigorous heat treatment to enhance the material's strength and durability. Furthermore, a strict quality control protocol, including pressure testing at levels exceeding standard working pressure, guarantees reliability and safety in every unit.

Wide-Ranging Applications

Primarily designed for the trucking and waste management industries, these hydraulic lifting rams are the powerhouse behind:

Skip Loaders: For efficient lifting and unloading of construction debris and waste containers.

Trailer Trucks: For reliable tipping and dumping of goods in logistics and agriculture.

Various other applications in recycling equipment, agricultural machinery, and industrial lifting platforms.

Conclusion

For businesses seeking a reliable, long-lasting, and high-performance hydraulic solution, our stainless steel double-acting cylinders represent the optimal choice. Their robust construction, superior materials, and precise engineering ensure maximum uptime and productivity for your fleet. Upgrade your equipment with a hydraulic ram built to endure and perform.

Name |

Push pull double acting tie rod welded piston hydraulic cylinder |

Working Pressure |

5800PSI max. |

Bore Dia. |

2''2.5''3''3.5''4''5'' |

Heat Treatment |

Quenching |

Sealing Parts |

From USA Herculesus |

Quality Guarantee |

1 year |

Inspection |

100% inspection before shipping |

Sample |

For free |

Certificate |

ISO9001:2008 |

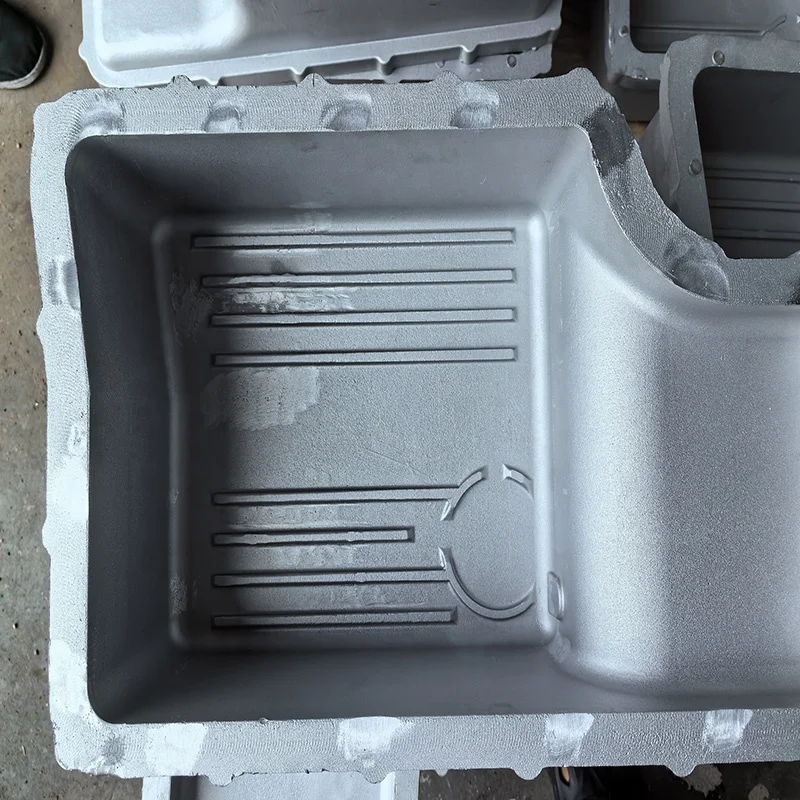

Packing |

Wooden Box |

Product Keywords |

one way hydraulic cylinder |