- Overview

- Recommended Products

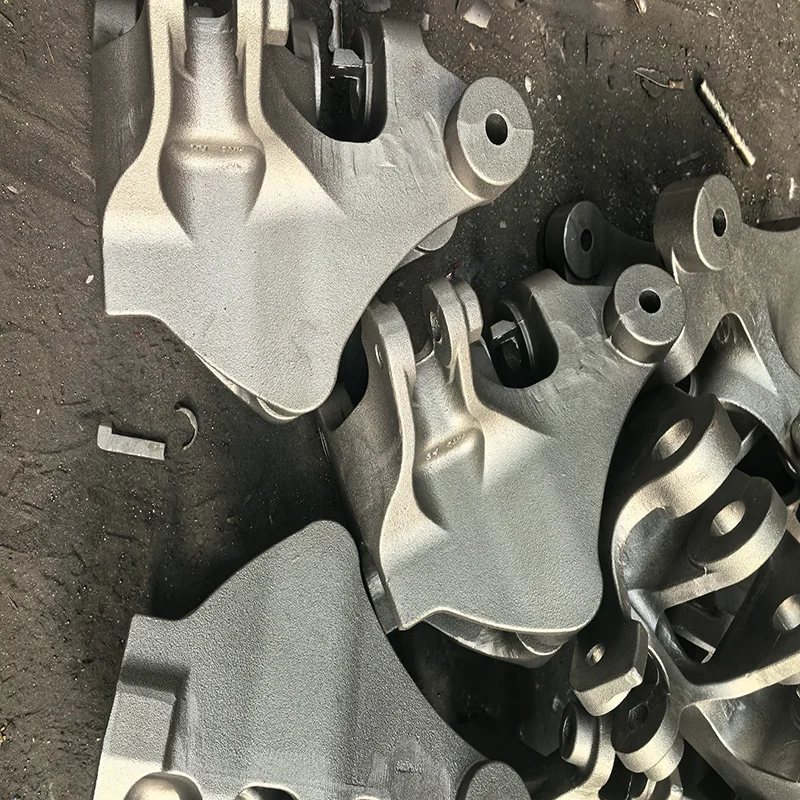

For industrial components requiring proven durability, cost-effectiveness, and reliable performance, grey iron remains a cornerstone material in metal casting. Our foundry specializes in High Quality Custom Sand Casting services, producing precision Grey Iron Casting components tailored to your exact specifications. We combine traditional foundry expertise with modern process control to deliver parts that meet the highest standards of integrity and performance.

Superior Material: The Strengths of Grey Iron

We utilize various grades of grey iron, known for its unique graphite flake microstructure. This structure provides a set of unmatched mechanical properties:

Excellent Vibration Damping: Grey iron absorbs and dissipates energy more effectively than steel and most other cast metals, making it ideal for machinery bases and engine components to reduce noise and fatigue.

Outstanding Wear Resistance: Its microstructure and ability to be hardened make it highly resistant to galling and abrasion.

Good Compressive Strength: Grey iron performs exceptionally well under high load-bearing applications.

Superior Machinability: It allows for faster machining speeds and longer tool life, significantly reducing secondary processing costs.

Controlled Sand Casting Production Process

Our sand casting process is optimized for flexibility, quality, and scalability, from prototype to high-volume production.

Pattern Making: We create precise wood, plastic, or metal patterns based on your CAD models, ensuring dimensional accuracy.

Mold and Core Creation: Chemically-bonded sand molds (such as resin shell or no-bake) are used to form the external and internal geometries of the part, allowing for complex shapes and hollow sections.

Melting and Pouring: We maintain strict control over the iron's chemistry and pouring temperature in our cupolas or electric furnaces to ensure consistent metallurgical properties.

Shakeout, Cleaning, and Inspection: After cooling, castings are cleaned, and critical quality checks—including dimensional verification and surface defect analysis—are performed.

Versatile Industrial Applications

Our custom grey iron castings are integral to numerous industries, including:

Automotive: Engine blocks, brake discs and drums, transmission cases.

Heavy Machinery: Pump housings, valve bodies, compressor frames, gearboxes.

Agricultural Equipment: Tractor components, implement housings.

General Industrial: Machine tool bases, hydraulic manifolds, counterweights.

Partner with our expert cast iron foundry for your next project. We provide the technical support and manufacturing excellence to deliver high-quality grey iron casting solutions that enhance your product's reliability and value.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |