- Overview

- Recommended Products

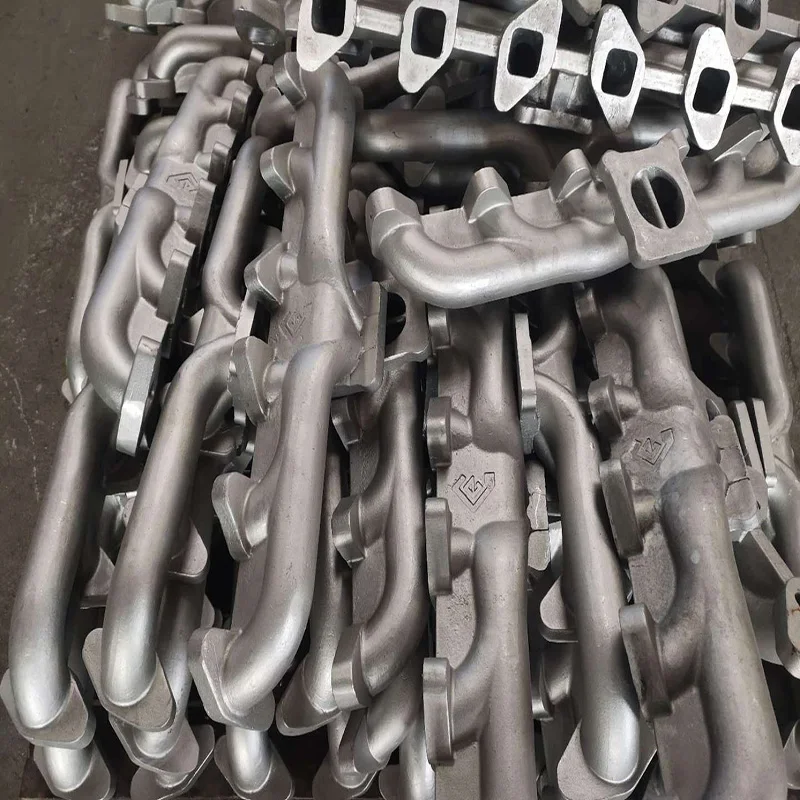

China's manufacturing expertise in producing high-quality cast steel bearing housings represents a pinnacle of industrial component manufacturing, combining advanced metallurgical knowledge with precision engineering to deliver products that meet global standards for reliability and performance in demanding applications.

Advanced Material Technology

Our bearing housings are manufactured using premium cast steel grades, primarily carbon steels (ASTM A216 WCB) and low-alloy steels, selected for their superior mechanical properties. These materials demonstrate:

Exceptional Tensile Strength: Ranging from 485-655 MPa, ensuring structural integrity under extreme loads

Superior Impact Resistance: Charpy V-notch values exceeding 27J at -29°C, guaranteeing performance in low-temperature environments

Excellent Wear Resistance: Hardness levels of 160-220 HB, providing longevity in abrasive conditions

Good Weldability: Facilitating easy repair and modification when necessary

Precision Manufacturing Processes

The production incorporates state-of-the-art foundry techniques:

Sand Casting Process: Utilizing resin sand molds for superior dimensional accuracy and surface finish

Computer-Aided Engineering: Implementing simulation software to optimize casting parameters and prevent defects

Controlled Heat Treatment: Normalizing and tempering processes to achieve desired mechanical properties

Advanced Machining: 5-axis CNC machining centers ensuring precise tolerances within ±0.05mm

Stringent Quality Assurance

Each housing undergoes comprehensive testing protocols:

Non-Destructive Testing: Magnetic particle and ultrasonic inspections detecting surface and subsurface defects

Dimensional Verification: Coordinate measuring machine (CMM) inspection ensuring geometric accuracy

Material Certification: Full traceability of chemical composition and mechanical properties

Pressure Testing: Hydrostatic testing validating housing integrity under operational pressures

Diverse Industrial Applications

These premium cast steel bearing housings serve critical functions across multiple sectors:

Heavy Machinery: Supporting rotating equipment in mining and construction applications

Power Generation: Housing bearings in turbines, generators, and pump systems

Marine Industry: Withstanding corrosive seawater environments in propulsion systems

Industrial Processing: Maintaining precision in conveyor systems and production machinery

China's cast steel bearing housing manufacturing combines traditional foundry expertise with modern technological innovations, delivering components that excel in durability, precision, and reliability for global industrial applications.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |