- Overview

- Recommended Products

Material Excellence and Performance Characteristics

GGG40 (also designated as EN-GJS-400-15) offers an optimal balance of tensile strength (400 MPa minimum), elongation (15% minimum), and impact resistance. The spherical graphite microstructure within the iron matrix provides exceptional mechanical properties that bridge the gap between cast steel and traditional cast iron. This material demonstrates excellent yield strength (250 MPa minimum) and maintains good toughness at low temperatures, along with superior vibration damping capacity and wear resistance. The inherent pressure tightness and machinability of GGG40 make it suitable for components subject to dynamic loading and hydraulic pressure requirements.

Advanced Sand Casting Manufacturing Process

Our foundry employs precision sand casting techniques specifically optimized for GGG40 ductile iron production. We utilize resin-bonded sand molding systems that maintain dimensional stability while accommodating complex geometries and varying wall thicknesses. The process includes controlled magnesium treatment to ensure proper nodularization of the graphite structure, followed by post-inoculation to achieve the required microstructure. Each casting undergoes rigorous quality control including ultrasonic testing, spectrographic analysis, and mechanical property verification. Our CNC machining capabilities then finish critical surfaces to tolerances within ±0.005 inches, ensuring perfect compatibility with mating components.

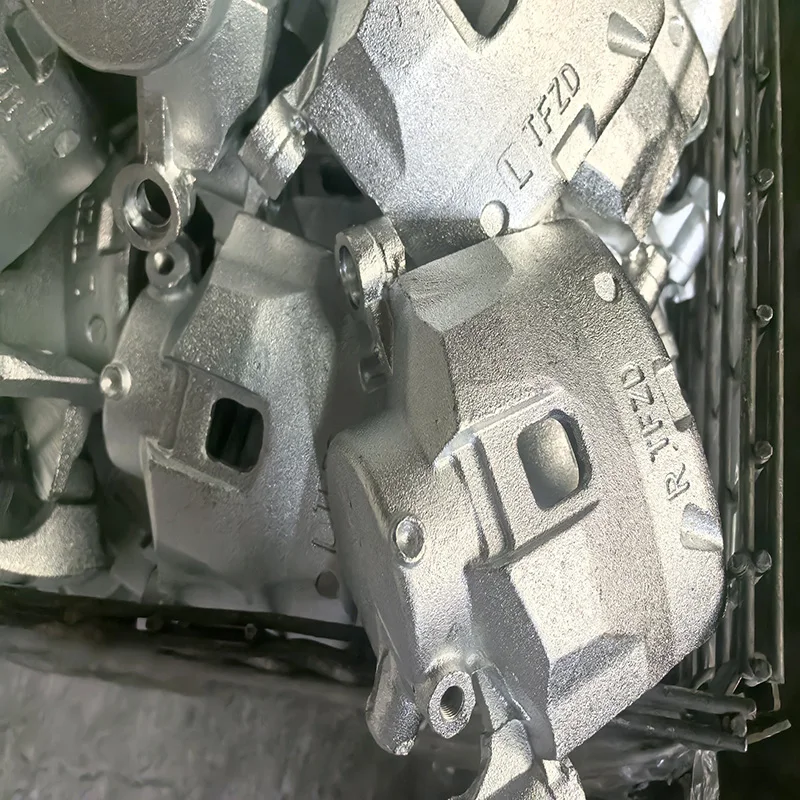

Comprehensive Industrial Applications

Our GGG40 sand cast components serve critical functions across multiple sectors. The automotive industry utilizes our castings for brake calipers, suspension components, and steering knuckles. In fluid handling applications, we produce pump housings, valve bodies, and pipe fittings that require pressure integrity. The construction and agricultural machinery sectors rely on our components for gearbox cases, axle supports, and structural frames. Additionally, wind energy, mining equipment, and heavy machinery manufacturers specify GGG40 for components subject to high dynamic stresses and demanding service conditions.

Partner with our foundry for GGG40 iron casting services that deliver uncompromising quality and performance. Our technical expertise in ductile iron metallurgy combined with precision sand casting capabilities ensures components that enhance product reliability, reduce weight compared to steel alternatives, and provide exceptional value across numerous industrial applications.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |