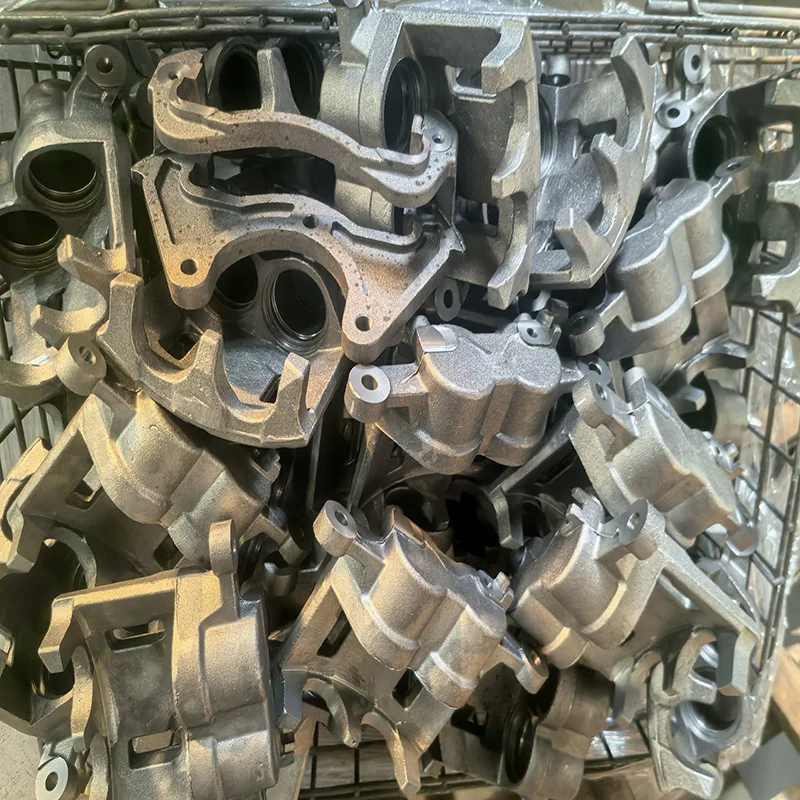

Factory-Direct Customized Iron Water Pump Machinery Parts High Quality Casting Services From China

- Overview

- Recommended Products

Sourcing durable and reliable water pump parts is critical for industrial and agricultural operations worldwide. China has emerged as a leading global provider of factory-direct, customized iron casting services, offering an unbeatable combination of quality, cost-effectiveness, and technical expertise. This capability is particularly evident in the production of high-performance iron water pump machinery parts, engineered to meet demanding specifications.

Robust Materials for Demanding Applications

The primary materials used are high-grade cast irons, selected for their exceptional mechanical properties and suitability for water applications. The most common types are:

Gray Iron (Gray Cast Iron): Celebrated for its excellent damping capacity, good machinability, and high compressive strength. It is ideal for pump housings, volutes, and brackets where vibration resistance is key.

Ductile Iron (Nodular Iron): Offers superior tensile strength, toughness, and impact resistance compared to gray iron, thanks to its spherical graphite nodules. It is the preferred choice for high-pressure pump impellers, shafts, and components subject to dynamic stresses.

These materials inherently provide excellent wear resistance and corrosion resistance, which are crucial for handling various water types, including fresh, saline, and abrasive-laden fluids.

Advanced and Precise Production Processes

Chinese foundries utilize sophisticated casting processes to ensure part integrity and dimensional accuracy:

Sand Casting: The most prevalent method for iron water pump parts, particularly for medium to high volumes and larger components. It allows for great flexibility in design and size. The use of resin sand molds ensures a superior surface finish and precise dimensional control.

Shell Molding: Often employed for smaller, more complex parts requiring a finer finish and higher accuracy than conventional sand casting.

CNC Machining: As a critical secondary operation, CNC machining guarantees that sealing surfaces, bolt holes, and mounting interfaces are finished to exact tolerances, ensuring perfect assembly and operation.

Wide-Ranging Applications

Customized iron cast parts are essential across numerous sectors:

Centrifugal Pumps: Housings, impellers, and wear rings.

Submersible Pumps: Motor enclosures and diffusers.

Irrigation and Agricultural Pumps: Volutes and bearing housings.

Industrial Cooling Systems: Various pump components and valve bodies.

By leveraging advanced metallurgy, proven casting techniques, and integrated machining, Chinese manufacturers provide factory-direct, high-quality iron casting solutions that ensure the longevity and efficiency of water pump systems globally.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |