- Overview

- Recommended Products

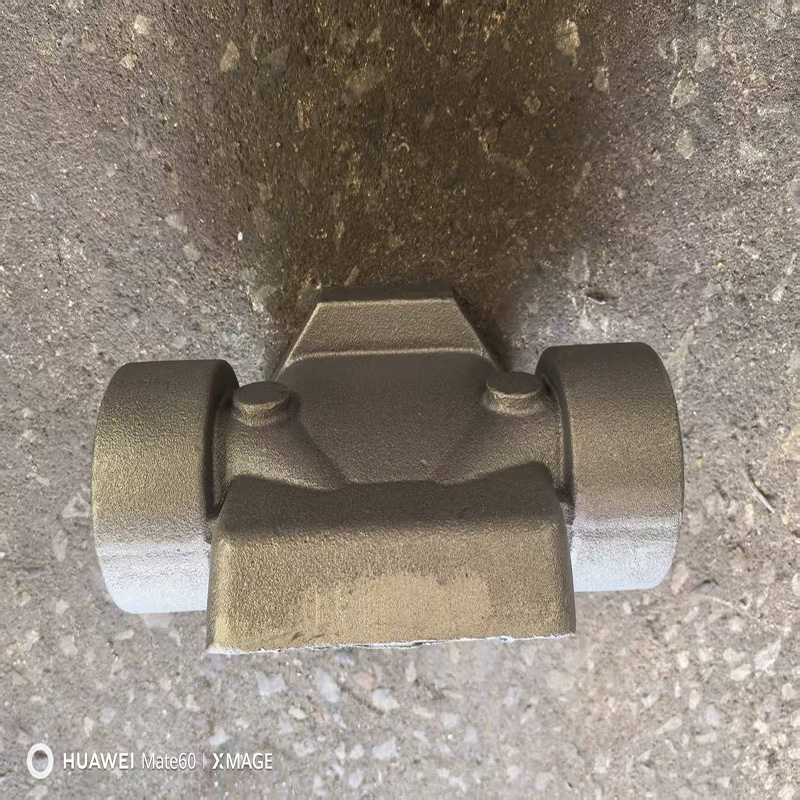

Comprehensive Automotive Casting Solutions

As a specialized manufacturer of automotive components, our factory provides complete metal casting services for auto parts production. We combine advanced foundry technologies with automotive industry expertise to deliver precision-cast components that meet rigorous quality standards and performance requirements for modern vehicle systems.

Advanced Material Selection

We utilize specialized alloys engineered for automotive applications:

Aluminum Alloys (A380, A356-T6): Optimal strength-to-weight ratio for fuel efficiency

Ductile Iron (65-45-12, 80-55-06): Superior strength and impact resistance

Gray Iron (Class 35-40): Excellent vibration damping characteristics

Stainless Steels (304, 410): Corrosion resistance for exhaust and exterior components

All materials comply with automotive industry standards and undergo rigorous chemical analysis and certification.

Enhanced Performance Characteristics

Our auto parts casting services deliver components with exceptional properties:

High strength-to-weight ratio supporting vehicle lightweighting initiatives

Excellent thermal conductivity for engine and transmission components

Superior corrosion resistance meeting automotive salt spray requirements

Consistent mechanical properties across production volumes

Reliable performance under extreme temperature variations

Enhanced durability exceeding 200,000-mile service life requirements

Integrated Manufacturing Process

Our automotive-focused production system ensures quality and consistency:

Casting Technologies:

High-pressure die casting for thin-wall components

Precision sand casting for complex geometries

Permanent mold casting for high-volume production

Lost foam casting for intricate designs

Quality Assurance:

IATF 16949 certified quality management system

Statistical process control throughout manufacturing

100% dimensional verification for critical components

Material traceability from raw material to finished part

Secondary Processing:

CNC machining maintaining ±0.01mm tolerances

Heat treatment for enhanced mechanical properties

Surface treatment and coating applications

Automated assembly and testing capabilities

Automotive Applications

Our casting services support all major vehicle systems:

Engine components: blocks, heads, manifolds

Transmission parts: housings, converters, cases

Suspension systems: knuckles, control arms, brackets

Braking components: calipers, drums, supports

Structural elements: crossmembers, frame components

Technical Capabilities

Component weight range: 0.5-50 kg

Annual production capacity: 15,000 tons

Dimensional tolerance: CT6-9 per ISO 8062

Surface finish: Ra 3.2-12.5 μm machined

Lead time: 4-8 weeks for production orders

Industry Compliance

IATF 16949:2016 Quality Management

ISO 14001 Environmental Management

RoHS and REACH compliance

Material certifications per customer requirements

Competitive Advantages

Automotive industry expertise and experience

Comprehensive engineering support

Cost-effective manufacturing solutions

Reliable delivery performance

Continuous quality improvement programs

By leveraging our specialized automotive casting capabilities and quality systems, we deliver components that meet the stringent requirements of modern vehicle manufacturing. Our technical expertise ensures optimal solutions for weight reduction, performance enhancement, and cost efficiency while maintaining the highest standards of quality and reliability expected by automotive manufacturers worldwide.

Our Services |

CNC Precision Milling Machining,CNC Precision Turning Machining, Rapid Prototyping Plastic Injection Mould Metal Stamping, Die Casting, Silicone And Rubber Mould, Aluminum Extrusion, Mould Fabrication,etc |

Material |

Aluminum Alloy:5052/6061/6063/7075 etc Brass Alloy: 3602/2604/h59/h62/etc Stainless Steel Alloy: 303/304/316/412/etc Steel Alloy: Carbon/Die Steel/etc Other Special Materials: Lucite/Nylon/Bakelite/etc Plastic, Wood, Silicone, Rubber,Or as per the customers’ requirements |

Surface Treatment |

Anodizing, Sandblasting, Painting, Powder coating, Electroplating, Silk Printing, Brushing, Polishing, Laser Engraving... |

Drawing Format |

X_T/jpg/pdf/dxf/dwg/igs/stp/step/stl,etc |

Service Project |

To provide project design, production and technical service, mould development and fabrication, etc |

Testing Machine |

Digital Height Gauge, caliper, Three Coordinate measuring machine, projection machine, roughness tester, hardness tester and so on |

Quality Assurance |

ISO9001:2015 Certified TUV |

Packing |

Foam, Carton, Wooden boxes, or as per the customer’s requirements |

Deliver |

DHL, FEDEX, UPS, TNT, EMS, SF Or according to customers′ requirement |