- Overview

- Recommended Products

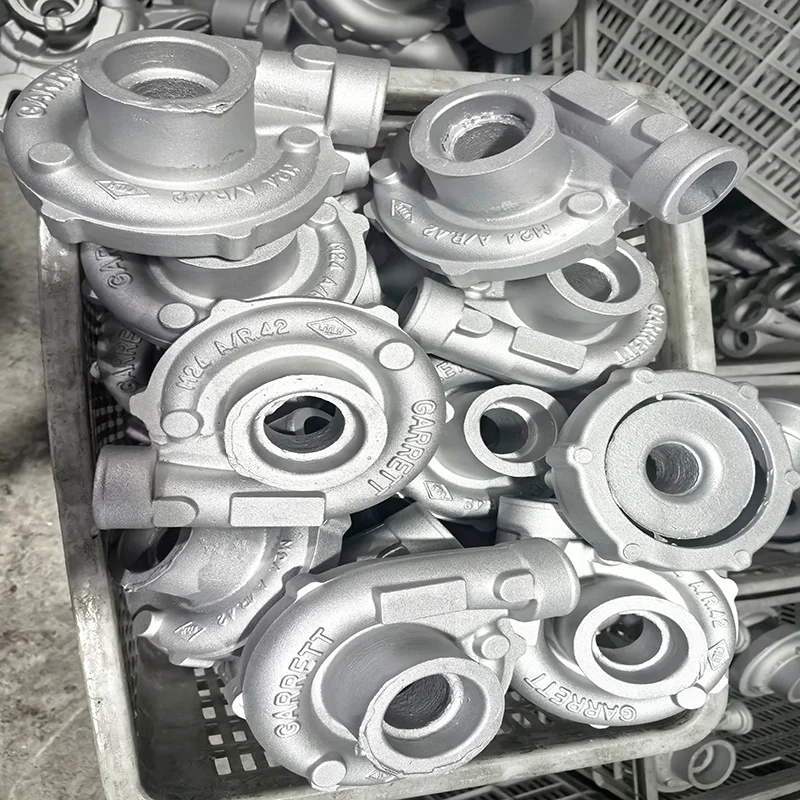

In the world of modern manufacturing, achieving the perfect balance of lightweight design, complex geometry, and high precision is a constant pursuit. As a central hub for integrated production, we specialize in aluminum components that merge the efficiency of die casting with the exacting accuracy of precision machining. This synergistic process delivers a final product that offers unparalleled structural integrity, dimensional consistency, and performance for the most demanding applications across automotive, aerospace, and consumer electronics.

Superior Material: Aluminum for Die Casting

The foundation of our product line is high-grade aluminum alloys, such as A380, ADC12, and A360. These specific alloys are selected for their ideal combination of properties for the die casting and machining processes:

Excellent Fluidity: Fills intricate mold cavities completely, enabling the production of complex, thin-walled geometries.

High Strength-to-Weight Ratio: Provides robust performance while minimizing component weight, a critical factor for fuel efficiency and portability.

Good Corrosion Resistance: Ensures long-term durability in various environmental conditions.

Superior Thermal and Electrical Conductivity: Makes it the material of choice for heat sinks and electronic enclosures.

Integrated Die Casting and Precision Machining Process

Our "central" approach means we control the entire workflow, ensuring seamless quality from molten metal to finished part:

High-Pressure Die Casting: The process begins with injecting molten aluminum into a precision-engineered steel mold under high pressure. This creates a near-net-shape part with excellent surface finish and a dense, fine-grained microstructure.

-

CNC Precision Machining: The die-cast part then moves to our precision machining centers. This is a critical value-added step where the part is transformed into a final, functional component. Our CNC milling, turning, and drilling operations:

Achieve critical tolerances on bearing bores and mounting holes.

Create precise threads and intricate features.

Machine flat sealing surfaces to ensure leak-proof assemblies.

Remove any minor casting artifacts for a flawless finish.

Key Performance Advantages of the Final Product

The synergy between die casting and machining results in a product with distinct benefits:

Design Freedom: Create complex, integrated parts that reduce assembly time and weight.

Cost-Effectiveness: Die casting is efficient for high volumes, while targeted machining minimizes material waste.

High Strength and Durability: The combination of a dense casting and machined, stress-relieved surfaces ensures reliability.

Exceptional Consistency and Quality: Every part is identical, guaranteeing performance and simplifying assembly.

Drive your innovation with components built for precision and performance. Contact us today to discuss your aluminum die casting and precision machining needs and experience the advantage of a centralized, integrated manufacturing solution.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |