- Overview

- Recommended Products

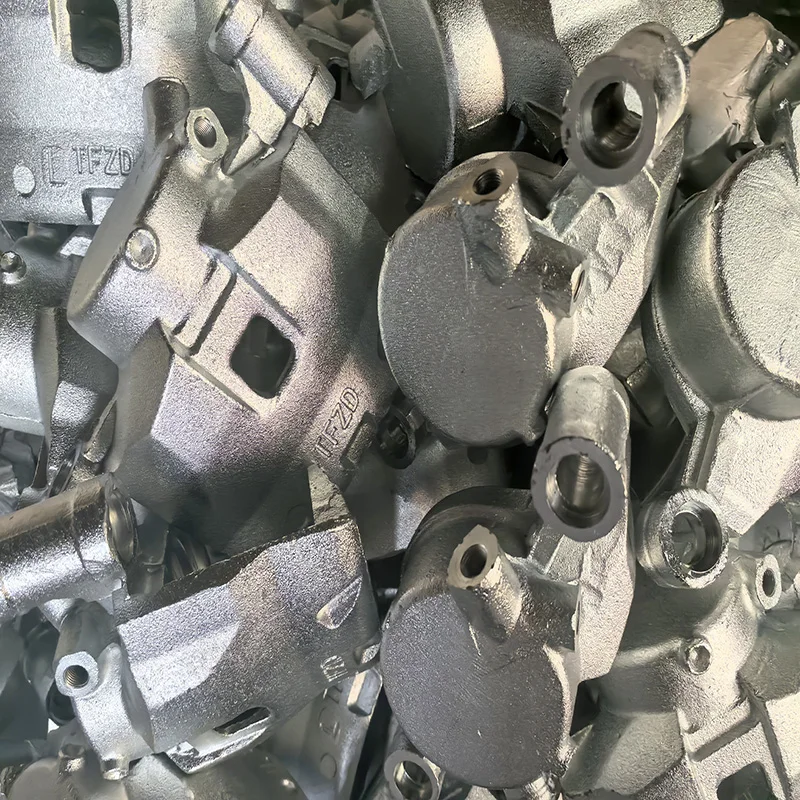

In the realm of robust and reliable industrial components, Customized Cast Ductile Iron Parts stand as a testament to modern metallurgical achievement. Manufactured primarily through the versatile sand casting process, these parts are engineered to meet the most demanding specifications for a wide array of machinery and infrastructure applications. For OEMs seeking a perfect blend of strength, durability, and design flexibility, custom ductile iron offers a superior solution.

The Superiority of Ductile Iron Material

Ductile Iron, also known as nodular or spheroidal graphite iron, is a ferrous alloy characterized by the presence of graphite in the form of spherical nodules. This unique microstructure is the source of its exceptional mechanical properties, which far surpass those of standard gray iron:

High Strength & Durability: Exhibiting tensile strength and yield strength comparable to many grades of steel.

Excellent Impact Resistance & Toughness: The nodular graphite structure gives ductile iron remarkable ductility, allowing it to absorb energy and deform without fracturing—a key advantage for parts subject to shock loads.

Good Wear Resistance: Suitable for applications involving friction and abrasion.

Superior Machinability: Despite its high strength, it can be efficiently machined to precise tolerances.

The Versatility of the Sand Casting Process

The sand casting method is ideally suited for producing customized ductile iron parts. This foundry process involves creating a mold from a sand aggregate, into which molten ductile iron is poured. Its key advantages for customization include:

Design Freedom: Capable of producing large, complex, and heavy parts that would be difficult or costly to make with other methods.

Cost-Effectiveness for Low to High Volumes: Especially economical for small batch production and large, one-off components like specialized pipe machine parts.

Rapid Prototyping: Allows for relatively quick iteration and production of prototype parts for testing and validation.

Performance and Application Excellence

The combination of ductile iron's inherent properties and the flexibility of sand casting results in components that deliver unparalleled performance in critical applications. These customized parts are indispensable in:

Water and Sewage Systems: As pressure pipes, valves, and fittings, leveraging the material's corrosion resistance and strength.

Heavy Machinery & Equipment: Components for construction, mining, and agricultural machinery requiring high strength-to-weight ratio and impact resistance.

Pipe Machines and Pump Housings: Where pressure integrity and durability are non-negotiable.

Power Generation and Automotive Industries: For crankshafts, gears, and other high-stress components.

Invest in the resilience and performance of customized sand-cast ductile iron. Contact us today to discuss your specific component requirements, receive expert design for manufacturability (DFM) feedback, and obtain a competitive quote for your project.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |