- Overview

- Recommended Products

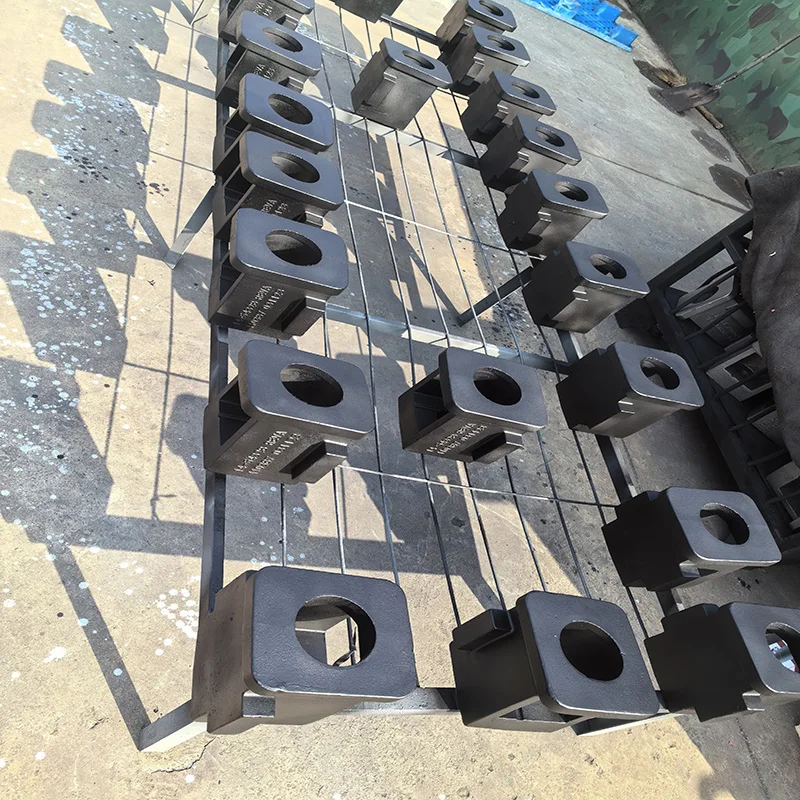

In the automotive industry, engine brackets play a critical role in maintaining stability and reducing vibrations. Our Custom QT450 Serpentine Engine Brackets, manufactured through advanced Iron Casting Services, deliver unmatched durability and precision for modern engine systems. Combining the superior material properties of QT450 with specialized casting techniques, these brackets ensure reliability in high-stress environments.

Advanced Material: QT450 Ductile Iron

QT450 ductile iron is a ferritic-type nodular iron renowned for its exceptional balance of strength and flexibility. Key properties include:

High Tensile Strength (450 MPa) and Yield Strength (250 MPa) , ensuring resistance to mechanical loads -9.

Elongation (10–15%) , providing superior ductility to withstand cyclic stresses without cracking -6-9.

Excellent Damping Capacity , reducing noise and vibrations in engine assemblies -2-9.

Good Machinability , allowing for precise post-casting modifications to meet tight tolerances -9.

These properties make QT450 ideal for serpentine engine brackets, which require fatigue resistance and dimensional stability under thermal and dynamic loads.

Precision Manufacturing Process

Our casting services integrate rigorous quality control with state-of-the-art production:

Sand Casting : Resin-bonded sand molds create complex bracket geometries with high dimensional accuracy -1-4.

Melting and Inoculation : Medium-frequency induction furnaces (e.g., 6-ton capacity) melt iron, while magnesium inoculation spheroidizes graphite for enhanced toughness -1-3.

Heat Treatment : Stress-relief annealing minimizes internal stresses, improving bracket stability -9.

CNC Machining : Critical mounting surfaces and holes are machined to ensure exact fitment -4-7.

This process guarantees brackets with uniform microstructures, pressure tightness, and compliance with ISO 9001/TS 16949 standards -4.

Performance Advantages

Lightweight Yet Robust : Optimized designs reduce weight without compromising strength.

Thermal Fatigue Resistance : Suitable for temperatures ranging from -20°C to 350°C -2.

Corrosion Resistance : Withstands exposure to engine oils and coolants -9.

Applications in Automotive Systems

QT450 serpentine brackets are essential for:

Engine Mounting Systems : Stabilizing main and auxiliary components -5.

Serpentine Belt Drive Assemblies : Supporting tensioners and idlers in powertrains -5.

Heavy-Duty Vehicles : Used in commercial trucks and machinery due to their impact resilience -6.

Quality Assurance

Every bracket undergoes:

Spectroscopic Analysis to verify chemical composition -4.

X-Ray Inspection for detecting internal defects -4.

Dimensional Checks via CMM and 3D scanners -4.

Conclusion

Our Custom QT450 Serpentine Engine Brackets exemplify engineering excellence, merging material superiority with precision casting. By leveraging QT450’s mechanical advantages and rigorous manufacturing protocols, we deliver components that enhance engine performance, reduce lifecycle costs, and meet global automotive standards. Partner with us for reliable, high-performance casting solutions tailored to your design requirements.

Product Description

| item | value |

| Place of Origin | China |

| - | Liaoning |

| Brand Name | Peng Xin |

| Model Number | Cast Iron Handwheel |

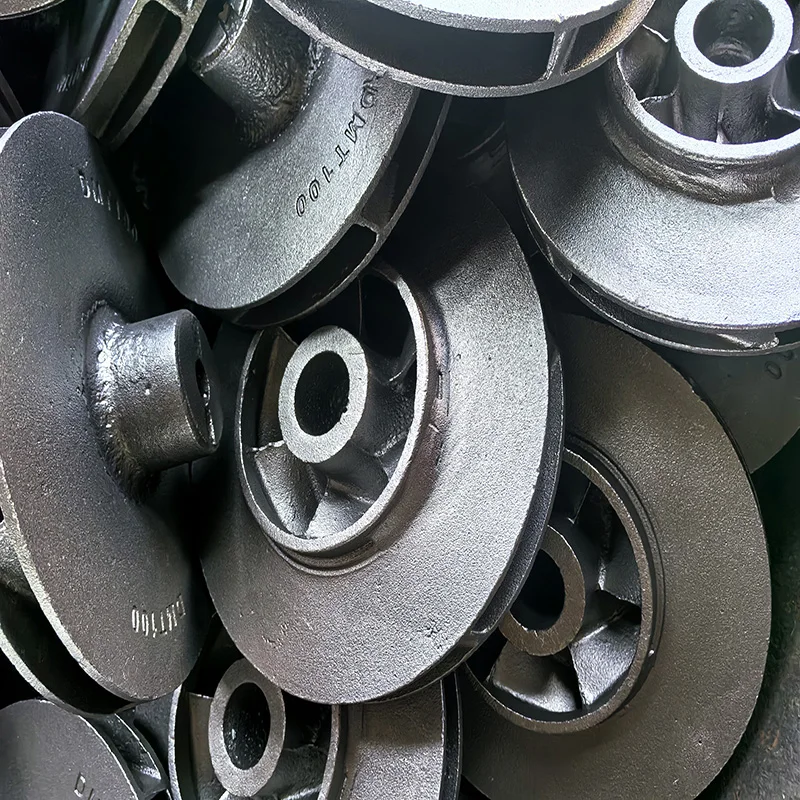

1.Product is a cast iron threaded hand wheel designed specifically for CNC milling machines. It features a high-quality appearance and is made of durable cast iron material, perfectly suitable for industrial and machinery applications. Approved with ISO9001 CE ROHS certifications, this hand wheel meets international quality standards.

2.Composed of premium cast iron and backed by a 3-month warranty, the product uses advanced casting processes and surface treatments, such as chromium electroplating, for exceptional durability and corrosion resistance. It offers optimal performance and is compatible with various brands, making it an excellent choice for CNC machining centers.

3.The customizable product comes with different color options (black, silvery white, bright chrome, and OEM) to match different machinery requirements. Offered at an attractive price, this hand wheel is competitively priced while maintaining a high standard of quality.

4.The company provides thorough documentation, including video outgoing-inspection and machinery test reports, ensuring customers receive a product in perfect condition. This transparency builds confidence in the quality and reliability of the product.

5.Through its extensive application across various industries, such as manufacturing plants and machinery repair shops, it has proven to perform reliably and effectively in demanding environments. The hand wheel's versatility and robust design make it adaptable for various CNC machine tool applications.

Dandong City Pengxin Machinery Co., Ltd. was founded in 1998 as a private enterprise specializing in casting, machining, and assembly. With a 66,000 square meters plant area and a production capacity of nearly 100,000 tons, the company employs 330 staff, including 46 technical and management personnel. The firm has strong partnerships with Dahua Kyrgyzstan, Changchun Yidong Clutch Co. Ltd., and SG Automotive Group, among others.

Equipped with advanced machinery such as the AMF-07L/R modeling lines, five sets of 1.5 tons electric furnaces, spectrometers, and CMMs, the company delivers quality, tailored products to European markets. Its network of machining centers, CNCs, drilling equipment, and boring machines make for efficient, in-house production.

The company is ISO9001 compliant and currently holds IATF 16949-2016 and AD2000-Merkblatt W0 certifications for quality and safety. It adopts state-of-the-art technology, including ISO14001 and OHSAS18001 certifications, emphasizing rigorous quality controls. With diverse clients like John Deere, Binotto, Mercedes-Benz, and Wilo, the company is primed for long-term, high-quality partnerships.

1. who are we?

We are based in Liaoning, China, start from 2020,sell to North America(42.00%),Western Europe(25.00%),Northern Europe(14.00%),Eastern Europe(11.00%),Southeast Asia(8.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Sand Casting,Shell Casting,Investment Casting,Gravity Casting,Machining Parts

4. why should you buy from us not from other suppliers?

Dandong City Pengxin Machinery Co., Ltd (PX-Casting) is a professional manufacture focusing on forging, casting and machinery. We produce forging & casting parts according to your own specifications via our highly-control production process. Our customiz

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency: USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken: English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian