- Overview

- Recommended Products

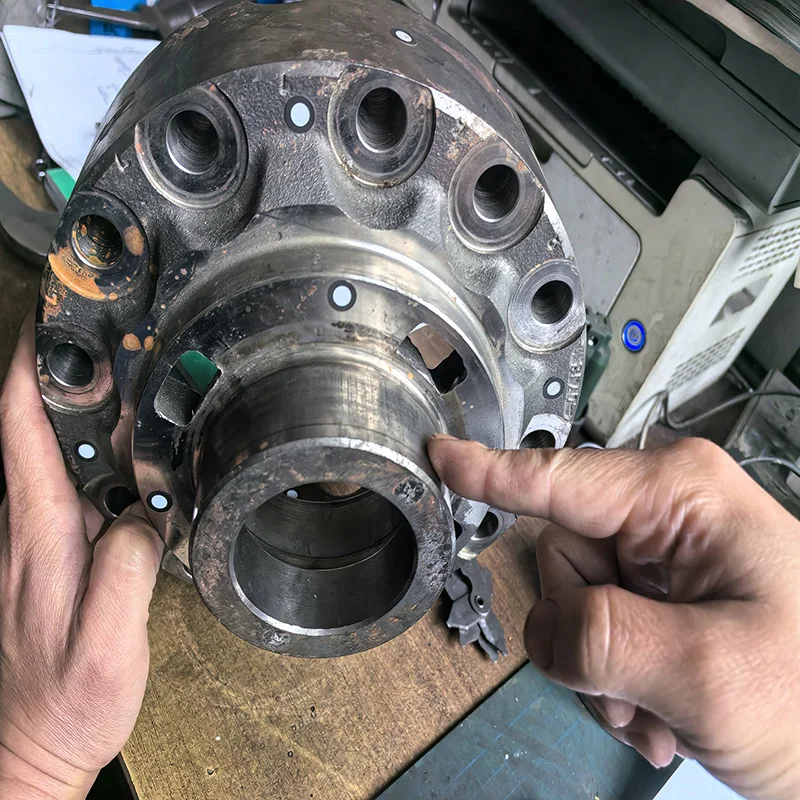

For industrial components demanding superior corrosion resistance and long-term durability, our custom metalworking services for galvanized iron casting parts deliver exceptional value. We specialize in high-quality sand casting production, combining metallurgical expertise with precision manufacturing to create components that withstand the test of time in even the most challenging environments.

Material Excellence: Galvanized Iron

Galvanized iron represents a significant advancement over standard iron castings through the application of a protective zinc coating. This galvanization process creates a metallurgically-bonded layer that serves as both a physical barrier and a sacrificial protector. The zinc coating actively prevents rust formation by corroding before the underlying iron, providing exceptional protection even when the surface becomes scratched or damaged. This dual-protection system ensures extended service life while maintaining the inherent strength and castability of iron.

Advanced Manufacturing Process

Our integrated manufacturing approach begins with precision sand casting, utilizing chemically-bonded sand molds to create complex geometries with excellent dimensional accuracy. The process encompasses pattern design, mold preparation, molten iron pouring, and controlled solidification. Following casting, we perform comprehensive metalworking operations including precision machining, surface grinding, and quality verification.

The critical galvanization phase employs both hot-dip galvanizing for heavy-duty applications and electro-galvanizing for components requiring tighter tolerances. Hot-dip galvanizing creates a thick, durable zinc-iron alloy layer that provides decades of protection, while electro-galvanizing offers a smoother, more uniform coating for precision components.

Performance Advantages & Applications

Galvanized iron castings deliver outstanding performance characteristics including:

Superior corrosion resistance in moist, acidic, or alkaline environments

Enhanced surface durability and wear resistance

Excellent mechanical strength and impact resistance

Long-term maintenance-free service life

These properties make our galvanized iron casting parts ideal for:

Marine & Offshore Equipment: Pump housings, valve bodies, and structural components

Infrastructure Applications: Bridge fittings, drainage components, and utility hardware

Agricultural Machinery: Equipment frames, bearing housings, and implement parts

Industrial Processing: Material handling components, conveyor parts, and machinery bases

By integrating expert sand casting with precision metalworking and protective galvanizing, we provide comprehensive manufacturing solutions that ensure component reliability and extended service life across diverse industrial applications.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |