- Overview

- Recommended Products

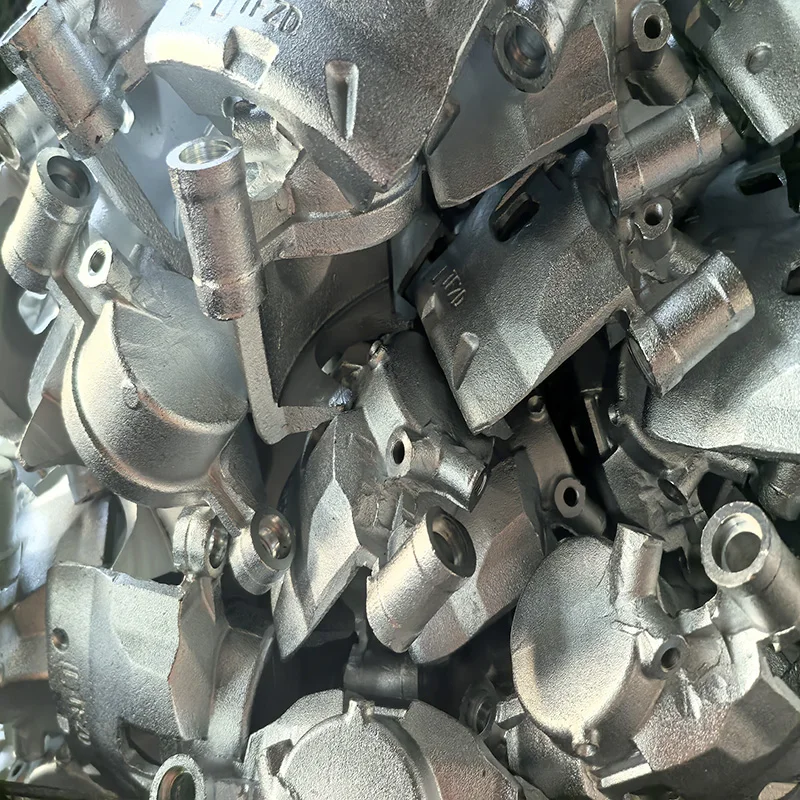

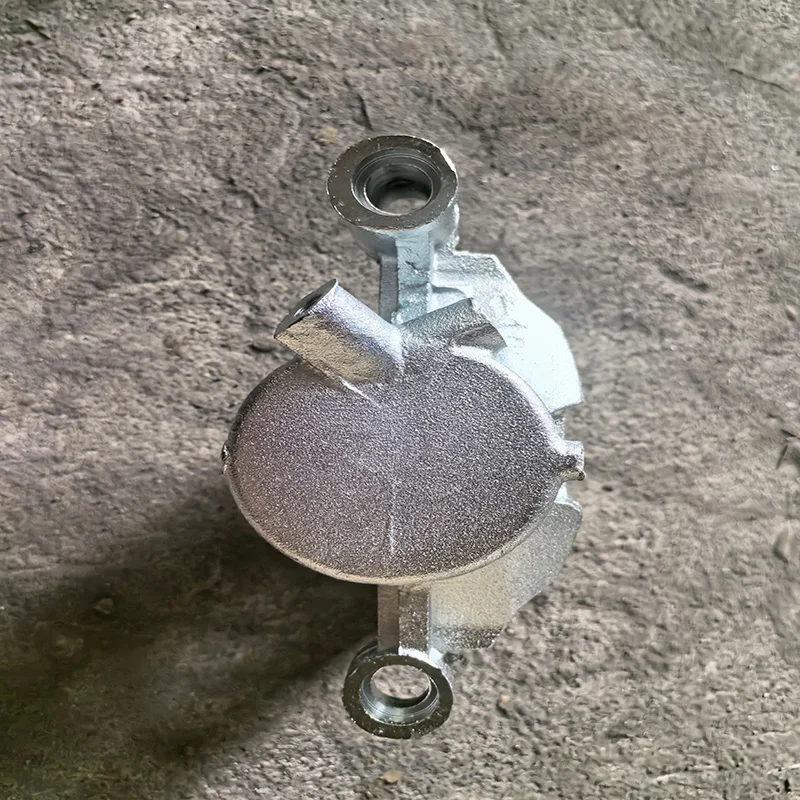

In the electrical industry, where electromagnetic properties, durability, and cost-efficiency are paramount, Custom Gray Cast Iron Electrical Components offer an optimal solution. Our Premium Casting Services specialize in producing these essential parts, enhanced with protective Zinc Plating to ensure long-term performance in diverse operating environments. We deliver components that combine the inherent advantages of gray iron with superior corrosion protection, meeting stringent requirements for electrical enclosures, motor housings, and power distribution equipment.

Superior Material: Engineered Gray Cast Iron

We utilize high-grade gray cast iron (ASTM Class 25-35), specifically selected for electrical applications due to its unique properties:

Excellent Damping Capacity: Effectively absorbs and dissipates electromagnetic vibrations and noise, leading to quieter operation and reduced stress on sensitive electrical connections.

Good Machinability: Allows for precision finishing of mounting surfaces, threaded holes, and complex geometries, ensuring perfect fit and assembly with other electrical system components.

High Compressive Strength: Provides robust structural support and protection for internal electrical parts, safeguarding them from physical impact and environmental stresses.

Outstanding Thermal Conductivity: Helps dissipate heat generated by electrical currents, preventing overheating and contributing to the overall stability and longevity of the electrical system.

Precision-Controlled Sand Casting Process

Our manufacturing relies on advanced sand casting techniques to ensure the integrity and dimensional accuracy of complex electrical parts:

Furan No-Bake Sand Molding: This modern molding process uses chemically-bonded sand to create molds with exceptional dimensional stability and a superior surface finish, ideal for the precise features required in electrical components.

Process Simulation: We employ casting simulation software to predict and prevent potential defects like shrinkage porosity, ensuring a sound and dense microstructure that is crucial for the component's structural and protective functions.

Rigorous Quality Control: Each casting undergoes thorough inspection to verify its integrity and dimensional conformity before proceeding to the plating stage.

Enhanced Protection with Zinc Plating

The application of zinc plating is a critical value-added step that significantly extends the service life of our gray iron components:

Electrolytic Galvanizing: We apply a uniform zinc coating through an electrochemical process, creating a robust sacrificial layer that protects the underlying iron from oxidation and rust, even if the coating is slightly scratched.

Corrosion Resistance: This plating is essential for components used in humid, industrial, or outdoor environments, providing effective protection against atmospheric corrosion.

Improved Surface Properties: The zinc coating also offers a cleaner, more aesthetically pleasing finish and can serve as a effective base for paint or additional coatings if required.

Proven Applications in Electrical Systems

Our custom zinc-plated, gray cast iron components are vital in:

Electrical Enclosures and Cabinets: Housing circuit breakers, contactors, and control systems.

Motor and Generator Housings: Providing structural frames and protective covers.

Transformer Bases and Brackets: Offering stable, vibration-damping support.

Power Distribution Equipment: Components for switchgear and busbar supports.

Partner with us for electrical components that guarantee durability, performance, and value. Our premium casting and plating services deliver parts that provide reliable electromagnetic shielding, structural support, and long-term corrosion resistance for your critical electrical infrastructure.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |