- Overview

- Recommended Products

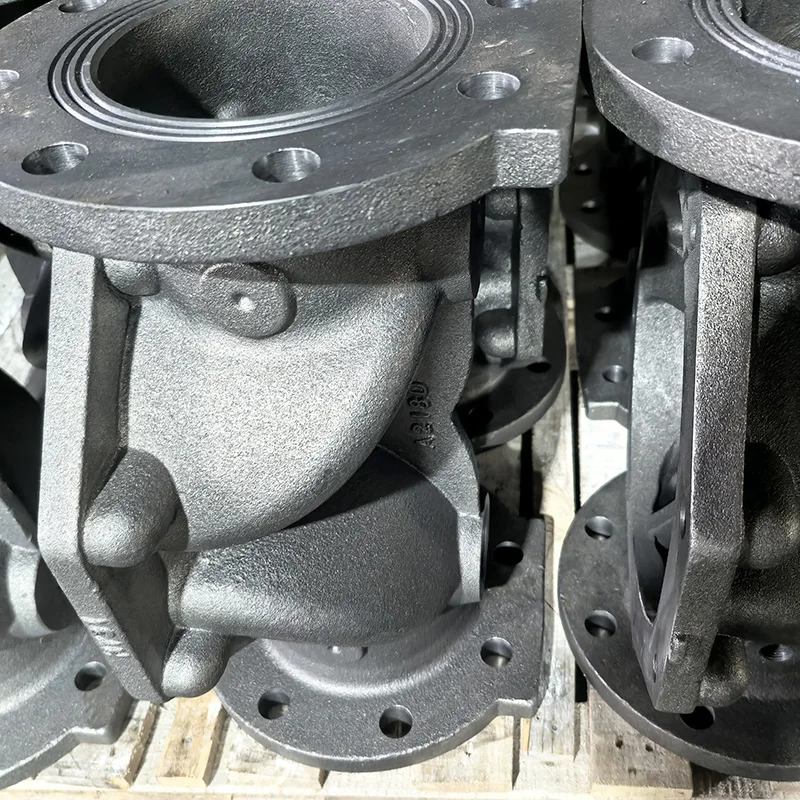

In demanding industrial applications, the integrity of core components is non-negotiable. Our Custom Cast Iron Cylinder Body Rod Premium Casting Services are engineered to deliver unparalleled performance, reliability, and longevity for hydraulic and pneumatic systems. We specialize in producing high-precision cylinder bodies and rods that form the backbone of heavy-duty machinery across various sectors.

Superior Material and Inherent Performance

We utilize high-grade cast iron, primarily gray iron (GG25/GG30) and ductile iron (GGG40/GGG50), chosen for their exceptional properties. Cast iron offers superior compressive strength, excellent wear resistance, and outstanding vibration damping capabilities. This is crucial for cylinder bodies that must withstand constant high pressure and pulsating loads without deformation or premature failure. The inherent graphite microstructure in our castings provides self-lubricating properties, further reducing wear on seals and extending the service life of the entire assembly.

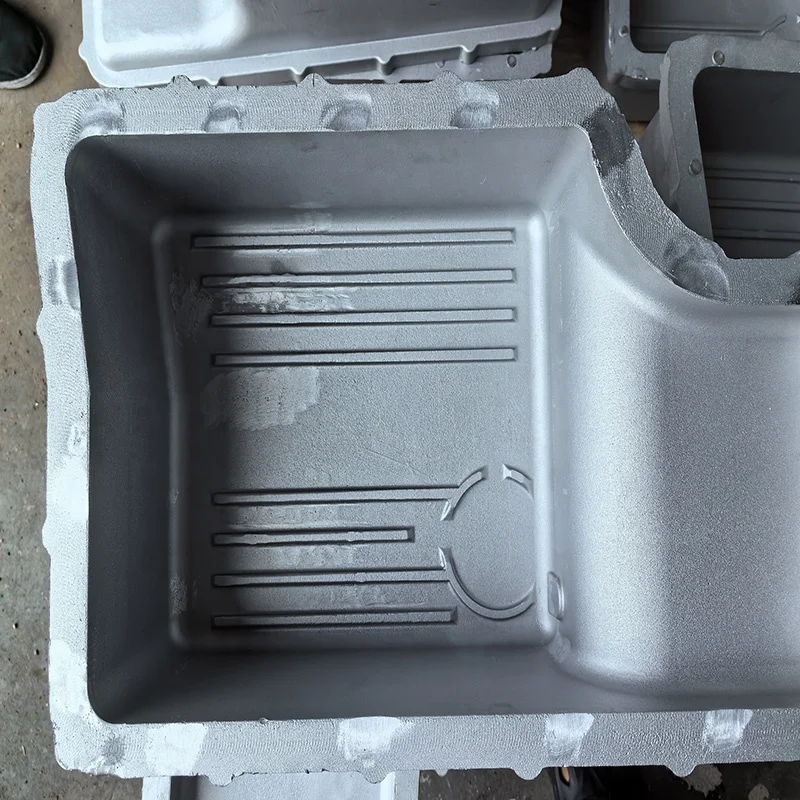

Advanced Production Process: Sand Casting and Beyond

Our premium service leverages advanced sand casting techniques, including resin sand casting and furan sand molding. These processes allow for the creation of complex internal passages and intricate geometries with exceptional dimensional accuracy and superior surface finish. The mold rigidity minimizes casting defects, ensuring a dense and homogeneous microstructure. Every casting undergoes rigorous quality control, including non-destructive testing (NDT) methods like magnetic particle or ultrasonic inspection, to guarantee internal soundness and freedom from flaws. Post-casting, we offer a full suite of machining services, including precision boring, honing, and threading, to achieve the exact tolerances and surface finishes required for a perfect seal and smooth piston rod operation.

Wide-Ranging Industrial Applications

Custom cast iron cylinder bodies and rods are critical components in numerous high-stakes industries. They are the power center of hydraulic presses, injection molding machines, and construction equipment like excavators and bulldozers. You will find our components in agricultural machinery, metal forming equipment, and marine applications, where their durability and resistance to harsh environments are paramount.

Partner with us for your next project. We provide end-to-end solutions from design consultation and prototyping to high-volume production, ensuring you receive a custom-engineered cylinder body rod that delivers maximum efficiency and reliability.

Material |

steel, stainless steel, aluminum,iron, carbon steel,copper, brass, alloy, etc. |

Thickness |

0.1mm to 12mm, as your request |

Sizes |

1) According to customers' drawings 2) According to customers' samples |

Surface treatment |

Anodizing, galvanized, zinc, nickle, chrome plating, powder coating, painting, etc. |

Drawing format |

DWG, DXF, STEP, STP, STL, AI,PDF, JPG, Draft. |

Packing |

Polybag+Carton box+Wooden case/Pallet, according to customer's request |

Shipment |

1) By courier, like DHL, TNT, Fedex, etc, usually 5-7 days to arrive |

2) By air to air port, usually, 3-4 days to arrive |

|

3) By Sea port, usually 15-30 days to arrive |

|

Delivery Time |

depend on the quantities, usually around 20 days. |

Payment Term |

T/T, Paypal, Trade Assurance |

Certification |

ISO |

Logo service |

provided |

Application |

widely used on construction, industry, automobile industry. |