Custom Agricultural Harvesting Finger Roller Star Wheel Screening Metal Products Factory Price Casting Services

- Overview

- Recommended Products

Maximizing agricultural efficiency and minimizing downtime are paramount for modern farming operations. Our specialized foundry provides Custom Agricultural Harvesting Components, including fingers, rollers, star wheels, and screening products, through high-performance casting services offered at competitive factory prices. We deliver durable, precision-made parts that are essential for the smooth functioning of combine harvesters and other critical machinery.

High-Performance Materials for Demanding Conditions

We understand that agricultural components face extreme abrasion, impact, and environmental stress. Our products are cast from specialized wear-resistant materials to meet these challenges. For high-impact parts like star wheels and rollers, we utilize high-carbon steel or ductile iron, which provide superior strength and excellent shock resistance. For components requiring extreme abrasion resistance, such as screening panels and harvesting fingers, we offer high-chromium white iron or manganese steel alloys. These materials develop exceptional hardness, significantly outlasting standard components and reducing the frequency of replacement, thereby lowering the total cost of ownership for our farming clients.

Precision-Oriented Production Process

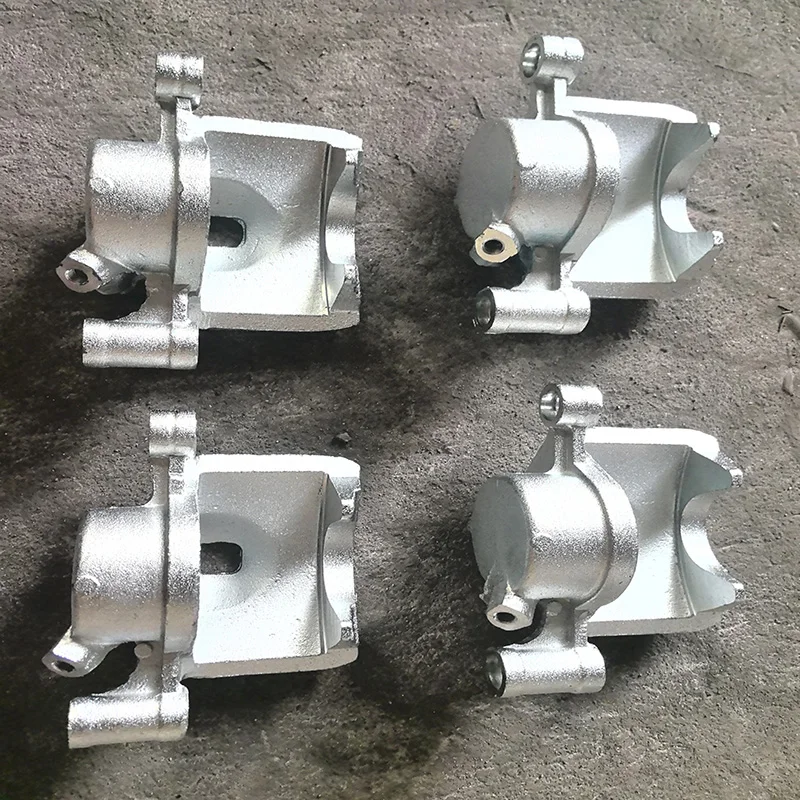

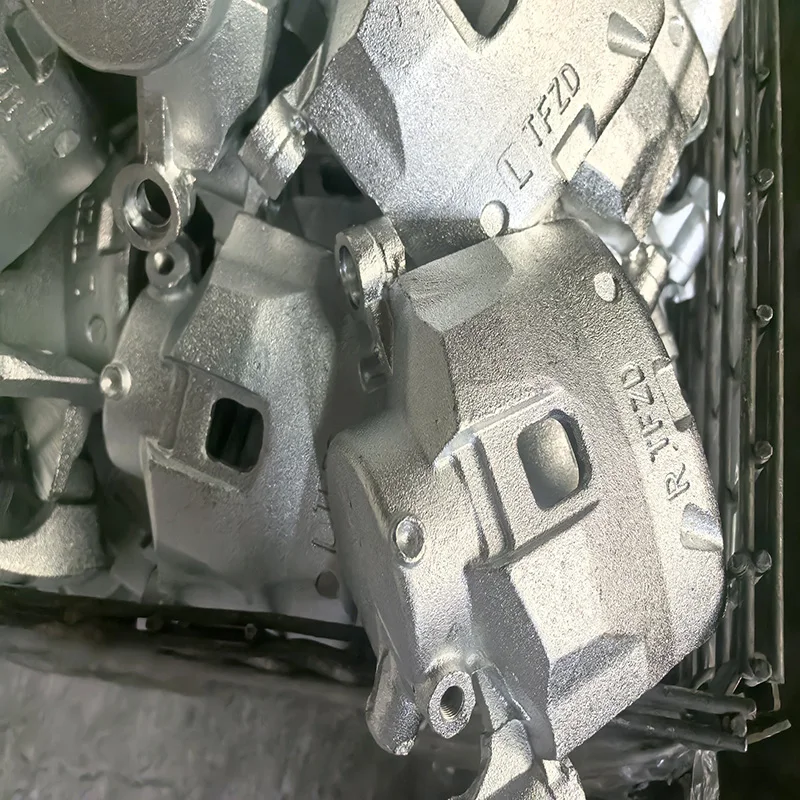

Our manufacturing process is tailored to produce complex agricultural parts with high dimensional accuracy and consistent quality. We primarily employ the Shell Molding Process (a type of sand casting) for producing these components. This technique uses a resin-coated sand to form a thin-walled, rigid mold, which results in a superior surface finish and tighter dimensional tolerances compared to conventional green sand casting. This is critical for parts like harvesting fingers, which require precise geometry to effectively separate grain from stalk. The process allows for high repeatability, ensuring every finger, roller, and star wheel performs identically. Post-casting, parts often undergo precise heat treatment to achieve the desired hardness and toughness, followed by machining on critical surfaces to ensure perfect fit and function within the harvester assembly.

Critical Applications in Agricultural Machinery

Our custom-cast metal products are integral to the performance of various harvesting implements:

Harvesting Fingers and Rollers: Central to the gathering and feeding mechanisms in combine headers, ensuring smooth crop flow.

Star Wheels: Guide crops into the header and assist in reel operation, requiring both durability and precise shape.

Screening Panels and Sieves: Used in the cleaning shoe of combines to separate grain from chaff, demanding high abrasion resistance and consistent perforation size.

By leveraging our specialized casting expertise and direct factory pricing, we provide the agricultural industry with reliable, high-wear parts that enhance harvesting efficiency, extend machinery life, and protect your bottom line.

Product Name |

casting parts/Die Casting Parts/sand casting part/aluminum die casting parts |

Casting Service |

Die Casting, Sand Casting, Gravity Casting, etc. |

Material |

QT200, 250,HT250, Aluminum ADC12, etc (Aupon your requirements.) |

Tooling Design |

We have own R&D team to make customized tooling, usually 7-15days can be ready. |

Standard |

China GB high precision standard. |

Surface Finish |

Mill Finishing, Anodizing, Powder coating, Wood grain, Polishing, Brushing, Electrophoresis. |

Drawing |

3D Drawing: .step / .stp, 2D Drawing: .dxf/ .dwg / .pdf |